نوفمبر . 07, 2024 03:23 Back to list

custom rubber strips

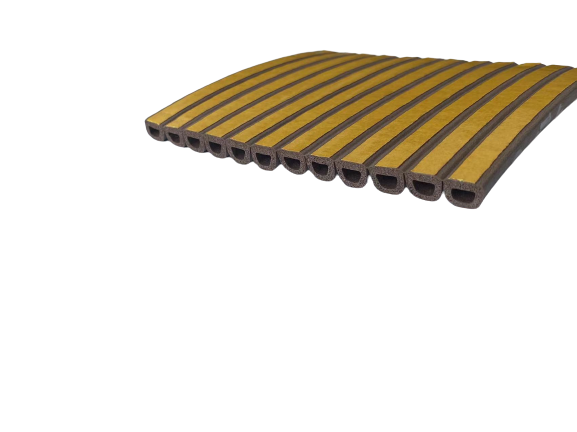

The Versatility of Custom Rubber Strips

In today's manufacturing and construction industries, the need for specialized components is more pressing than ever. Among the many solutions available, custom rubber strips stand out due to their versatility, durability, and effectiveness across a range of applications. Whether for sealing, insulation, or cushioning, these tailored solutions can enhance product performance and longevity.

What Are Custom Rubber Strips?

Custom rubber strips are specially designed and manufactured rubber components tailored to the specific needs of a project. They can be produced in various sizes, shapes, and rubber formulations to suit different environmental conditions and mechanical requirements. The customization aspect allows manufacturers to optimize the functionality and fit of these strips, addressing unique challenges that standard products might not resolve.

Applications Across Industries

1. Construction In construction, custom rubber strips are often used for sealing windows, doors, and structural joints, preventing water, dust, and noise intrusion. They can also provide thermal insulation, which is critical in energy-efficient building designs.

2. Automotive The automotive industry relies heavily on custom rubber strips for a variety of purposes, from weather stripping that enhances vehicle aerodynamics to gaskets that ensure tight seals in engines and transmissions. Their resilience to weathering and temperature variations makes them ideal for automotive applications.

custom rubber strips

3. Manufacturing In manufacturing environments, these rubber strips play a significant role in machine protection and vibration dampening. By absorbing shocks and vibrations, they help to maintain equipment integrity and prolong the life of machinery.

4. Electronics In the electronics sector, custom rubber strips can be used to create seals for electronic enclosures, protecting sensitive components from dust, moisture, and electrostatic discharge.

Benefits of Customization

The key advantage of custom rubber strips is the ability to tailor materials and dimensions to meet specific needs. Depending on the application, manufacturers can choose from various rubber compounds, such as neoprene, silicone, or EPDM, each offering distinct advantages in terms of temperature resistance, flexibility, and chemical compatibility.

Additionally, customization enables companies to optimize production processes, reduce waste, and lower costs by ensuring that only precisely what is needed is produced. This not only enhances efficiency but also contributes to sustainability efforts.

Conclusion

As industries continue to evolve, the demand for custom rubber strips will only grow. Their ability to meet specific requirements makes them an indispensable component in a variety of applications. By investing in custom solutions, businesses can enhance their product offerings, improve performance, and ultimately achieve greater customer satisfaction. Whether in construction, automotive, manufacturing, or electronics, custom rubber strips will undoubtedly play a crucial role in supporting innovative designs and efficient operations.