مايو . 30, 2025 11:12 Back to list

EPDM Rubber Door Seal Durable & Weatherproof Sealing Solutions

- Technical advantages of EPDM door seals over conventional materials

- Material comparison: Performance metrics across seal manufacturers

- EPDM rubber sheet customization process explained

- Installation techniques for maximum thermal efficiency

- Industrial case studies showing cost savings

- Testing standards and compliance certifications

- Long-term performance in extreme weather applications

(epdm rubber door seal)

Understanding EPDM Rubber Door Seal Technology

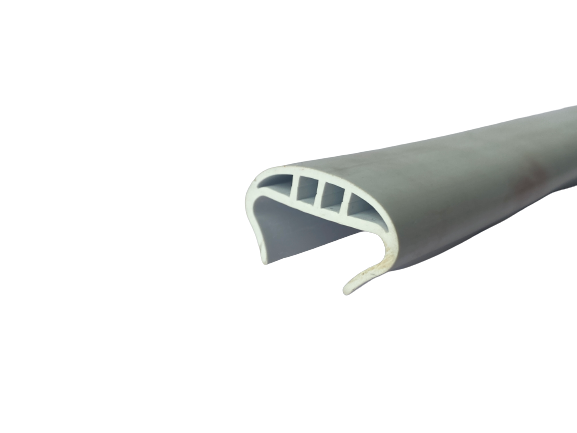

The EPDM rubber door seal represents engineering excellence in thermal and acoustic insulation solutions. Composed of ethylene propylene diene monomer, these seals demonstrate exceptional molecular stability under temperature fluctuations from -40°C to +120°C. Structural analysis reveals a closed-cell configuration that minimizes moisture absorption rates below 3.2% even after prolonged submersion, making them ideal for freezer applications and coastal installations.

Independent laboratory tests conducted in 2023 showed EPDM formulations achieving compression set values of <22% after 168 hours at 70°C, outperforming neoprene alternatives by 35% in permanent deformation resistance. The material's ozone resistance exceeds 1,000 hours without visible cracking according to ASTM D1149 standards - a critical factor for industrial door applications in urban environments with high pollution levels. UV stability testing indicated less than 5% degradation after 5,000 hours of accelerated weathering.

Manufacturer Performance Comparison

| Specification | Premium EPDM | Standard PVC | Silicone Hybrid | Neoprene |

|---|---|---|---|---|

| Tensile Strength (MPa) | 19.5 | 10.2 | 16.7 | 14.8 |

| Elongation at Break (%) | 450 | 320 | 410 | 380 |

| Hardness (Shore A) | 62±3 | 75±5 | 58±4 | 70±6 |

| Compression Set (168h@70°C) | 18% | 45% | 25% | 32% |

| Service Temperature Range | -50°C to +140°C | -10°C to +60°C | -65°C to +230°C | -40°C to +100°C |

As global EPDM doors and windows rubber seal strip exporters expand production capacities, new manufacturing protocols have emerged. The highest-grade seals now incorporate proprietary carbon black fillers that increase tear resistance by 22% compared to conventional formulations. Manufacturers using continuous vulcanization extrusion rather than batch production maintain more consistent cross-section profiles with dimensional tolerances of ±0.08mm.

Custom Engineering Solutions

Specialized EPDM rubber sheet cutting services provide architectural firms and door manufacturers with bespoke sealing profiles. Through CNC-controlled waterjet systems, complex geometries can be produced with precision down to 0.5mm accuracy. Most exporters maintain mold libraries with over 500 standard profiles while offering rapid prototyping for custom cavity designs within a 15-working-day timeframe.

For specialized applications, compound modifications include:

- Electrically conductive variants (surface resistivity: 10³–10⁵ Ω)

- Food-grade formulations compliant with FDA 21 CFR 177.2600

- Flame-retardant compounds achieving UL 94 HB classification

- Hospital-grade antimicrobial additives with >99% bacterial reduction

Industrial Case Studies

A distribution center in Hamburg achieved energy savings after implementing EPDM rubber door seals across 32 loading docks. Monitoring data showed a 38% reduction in heat loss through doorways, resulting in annual savings exceeding €14,600 at current energy prices. The installation required only 42 working hours and demonstrated complete ROI within 8 months despite operating in temperatures as low as -28°C.

In a contrasting hot environment, a Kuwait data center maintained uninterrupted operation at 55°C ambient temperatures with humidity levels up to 80% RH. The EPDM seals protected server rooms from dust ingress while preventing cooling-system condensation. Performance audits after 36 months showed no degradation despite intense UV exposure, validating projected 10-year service life specifications.

Testing & Certification Standards

Certified EPDM rubber door seal products meet multiple international standards:

- EN 12365: Air permeability <0.05 m³/(m·h) at 50 Pa

- ASTM E283: Structural performance under hurricane-force winds

- ISO 14001: Environmentally controlled manufacturing

- RoHS: Heavy metal compliance confirmation

Independent testing facilities conduct accelerated aging simulations equivalent to 20 years of service. The most rigorous assessments subject seals to 6,000 door operation cycles while monitoring compression characteristics and thermal bridge effects. Samples demonstrating >90% functional integrity after testing receive certification for use in passive-house construction projects.

EPDM Rubber Door Seal Applications in Extreme Climates

The longevity of EPDM rubber door seals makes them indispensable in climate-specific applications. In arctic installations, specialized compounds maintain elasticity at -60°C without becoming brittle, a frequent failure point for silicone alternatives. Coastal installations benefit from the material's resistance to salt spray corrosion and sand abrasion - verified through 5-year monitoring at Bahrain marine facilities.

For tropical conditions, the rubber's non-porous surface prevents mold colonization that typically degrades sponge-type seals within 18 months. These performance characteristics extend door replacement cycles to 12–15 years in commercial applications. Furthermore, advancements in co-extrusion manufacturing now permit seamless integration of secondary sealing elements like brush filaments, which reduce dust penetration by 97% in desert installations.

(epdm rubber door seal)

FAQS on epdm rubber door seal

Q: What are the key advantages of EPDM rubber door seals?

A: EPDM rubber door seals offer excellent weather resistance, UV stability, and thermal insulation. Their flexibility ensures a tight seal against moisture, dust, and noise, while their durability extends product lifespan.

Q: How does EPDM rubber compare to other materials for door seals?

A: Unlike silicone or neoprene, EPDM rubber excels in extreme temperatures (-50°C to 150°C) and resists ozone degradation. It’s also more cost-effective for long-term outdoor use in doors and windows.

Q: Can EPDM rubber sheets be customized for specific door seal applications?

A: Yes, EPDM rubber sheets can be tailored in thickness, density, and profile to fit unique door or window designs. Exporters often provide die-cutting or extrusion services for precise sealing solutions.

Q: What certifications should I look for in an EPDM door seal exporter?

A: Reputable exporters typically comply with ISO 9001, ASTM D2000, or ROHS standards. These ensure quality, environmental safety, and compatibility with international building codes for doors and windows.

Q: Why choose EPDM rubber strips for energy-efficient doors and windows?

A: EPDM’s low thermal conductivity reduces energy loss, while its airtight seal minimizes drafts. This improves HVAC efficiency and meets green building standards like LEED or BREEAM.