ديسمبر . 21, 2024 09:52 Back to list

Factory Manufacturing Marine Sealing Strips for Enhanced Waterproof Solutions in Nautical Applications

Marine Sealing Strip Factory Ensuring Quality and Durability in Marine Applications

In the maritime industry, where equipment and structures are exposed to harsh environments, the importance of reliable sealing solutions cannot be overstated. This is where marine sealing strip factories come into play. These specialized manufacturers are dedicated to producing high-quality sealing strips designed to withstand the rigors of marine applications, ensuring that vessels maintain their integrity and performance under challenging conditions.

Understanding Marine Sealing Strips

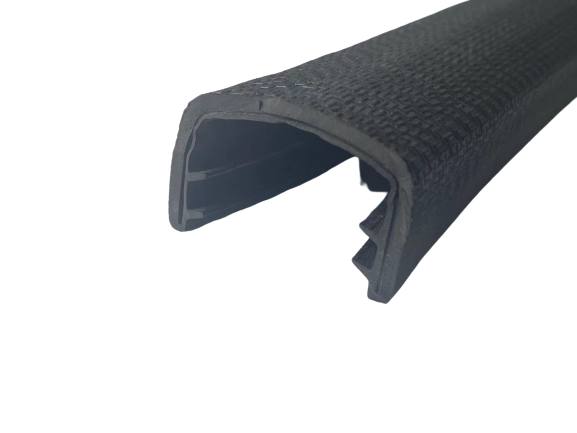

Marine sealing strips serve a critical function in various applications, including boats, ships, underwater equipment, and coastal infrastructures. They are utilized to create airtight and watertight seals that prevent the ingress of water, salt, and other corrosive elements. This is crucial not only for the protection of the equipment but also for the safety of the crew and passengers. High-quality sealing strips are designed to endure extreme temperatures, UV exposure, and mechanical wear, ensuring long-lasting performance in demanding environments.

Manufacturing Process

The manufacturing of marine sealing strips involves several steps, each requiring precision and attention to detail. The process typically begins with the selection of high-grade materials that possess excellent resistance to corrosion and degradation. Common materials used in marine sealing strips include EPDM (Ethylene Propylene Diene Monomer), silicone, and PVC (Polyvinyl Chloride), all known for their durability and strength.

Once materials are selected, the manufacturing process includes extrusion, molding, or die-cutting techniques to create the desired shapes and sizes of the sealing strips. Advanced machinery is employed to ensure that each product meets the specified dimensions and tolerances, as even the slightest deviation can compromise the sealing effectiveness.

After molding or extrusion, sealing strips undergo rigorous quality control tests. These tests may include pressure, temperature stability, and flexibility assessments to ensure that the final product adheres to industry standards and regulations. Factories often adhere to strict ISO certification processes to guarantee quality, reliability, and customer satisfaction.

marine sealing strip factory

Customization for Diverse Needs

One of the standout features of marine sealing strip factories is their ability to provide customized solutions. Every marine application has unique requirements, so manufacturers often work closely with clients to create tailored sealing solutions that meet specific dimensions, environmental conditions, and performance standards. Customization may also extend to color, shape, and material composition, allowing vessels and equipment to not only perform effectively but also look aesthetic.

Sustainability and Environmental Considerations

In recent years, the emphasis on sustainability has led marine sealing strip factories to adopt eco-friendly materials and production methodologies. Manufacturers are increasingly focused on reducing their carbon footprint by utilizing recyclable materials, minimizing waste during production, and implementing energy-efficient processes. By prioritizing sustainability, marine sealing strip factories contribute to the broader objectives of environmental conservation and green manufacturing.

Conclusion

The role of marine sealing strip factories in the maritime industry cannot be understated. By providing quality sealing solutions that ensure the durability and efficiency of marine applications, these manufacturers play a vital part in maintaining vessels and equipment in optimal condition. The intricate processes involved in the production of marine sealing strips showcase a commitment to excellence, innovation, and customization in meeting diverse client needs.

As the maritime industry continues to grow and evolve, so too will the technologies and methodologies employed by marine sealing strip factories. The focus on quality, sustainability, and customer-centric solutions will ensure that these manufacturers remain at the forefront of the industry, delivering sealing products that meet the demands of modern marine applications while protecting the environment. Whether it’s a small boat or a large naval vessel, the assurance of quality sealing strips can significantly enhance performance, safety, and longevity, underscoring the essential role of marine sealing strip factories in the maritime ecosystem.