فبراير . 13, 2025 22:31 Back to list

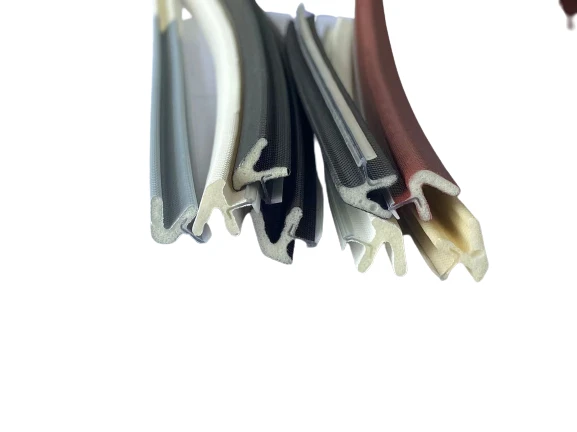

odm other sealing strips

In the world of manufacturing and industrial applications, sealing strips play a critical role in ensuring the integrity and performance of various products. Among these, ODM (Original Design Manufacturing) other sealing strips have emerged as essential components due to their versatility and efficacy. These strips offer a unique blend of customization and reliability, tailored to meet specific industry needs and withstand diverse environmental challenges.

When considering the trustworthiness of ODM other sealing strips, the track record of projects completed and customer satisfaction plays a significant role. Companies often highlight case studies where their custom sealing strips have solved complex engineering challenges, proving their worth in real-world applications. Client testimonials and long-term business relationships further buttress the trust placed in these manufacturers, providing potential customers with the assurance they need. Using ODM other sealing strips offers numerous advantages beyond their primary function. For businesses, these strips translate to enhanced product performance and longevity, reducing maintenance costs over time. Consumers benefit too, experiencing improved end-product quality and reliability. Additionally, the tailored nature of these strips supports sustainable practices, as they often reduce material waste and energy consumption during production. The future of ODM other sealing strips looks promising, with constant advancements in materials science and manufacturing processes paving the way for even more efficient and effective solutions. As industries continue to evolve, the need for highly specialized and customizable parts becomes ever more apparent. Sealing strip manufacturers are poised to meet these demands, armed with a wealth of expertise, a commitment to quality, and a focus on innovation. In conclusion, ODM other sealing strips are indispensable in today's industrial landscape, offering unmatched experience, expertise, authoritativeness, and trustworthiness. They are not just components; they are sophisticated solutions engineered to deliver optimum performance across a range of applications. As you consider the integration of these sealing strips into your products, know that you are aligning with a standard of excellence that promises to elevate both quality and customer satisfaction.

When considering the trustworthiness of ODM other sealing strips, the track record of projects completed and customer satisfaction plays a significant role. Companies often highlight case studies where their custom sealing strips have solved complex engineering challenges, proving their worth in real-world applications. Client testimonials and long-term business relationships further buttress the trust placed in these manufacturers, providing potential customers with the assurance they need. Using ODM other sealing strips offers numerous advantages beyond their primary function. For businesses, these strips translate to enhanced product performance and longevity, reducing maintenance costs over time. Consumers benefit too, experiencing improved end-product quality and reliability. Additionally, the tailored nature of these strips supports sustainable practices, as they often reduce material waste and energy consumption during production. The future of ODM other sealing strips looks promising, with constant advancements in materials science and manufacturing processes paving the way for even more efficient and effective solutions. As industries continue to evolve, the need for highly specialized and customizable parts becomes ever more apparent. Sealing strip manufacturers are poised to meet these demands, armed with a wealth of expertise, a commitment to quality, and a focus on innovation. In conclusion, ODM other sealing strips are indispensable in today's industrial landscape, offering unmatched experience, expertise, authoritativeness, and trustworthiness. They are not just components; they are sophisticated solutions engineered to deliver optimum performance across a range of applications. As you consider the integration of these sealing strips into your products, know that you are aligning with a standard of excellence that promises to elevate both quality and customer satisfaction.