نوفمبر . 11, 2024 06:13 Back to list

ship anti-collision rubber sealing strip factories

The Importance of Ship Anti-Collision Rubber Sealing Strips

In the maritime industry, safety is paramount. One of the vital components in ensuring the protection of vessels and their crews is the effective use of anti-collision rubber sealing strips. These specialized products play a critical role in preventing damage during docking and collision scenarios, thereby safeguarding both ships and ports. Understanding their importance, manufacturing processes, and applications can help reinforce maritime safety standards.

What Are Anti-Collision Rubber Sealing Strips?

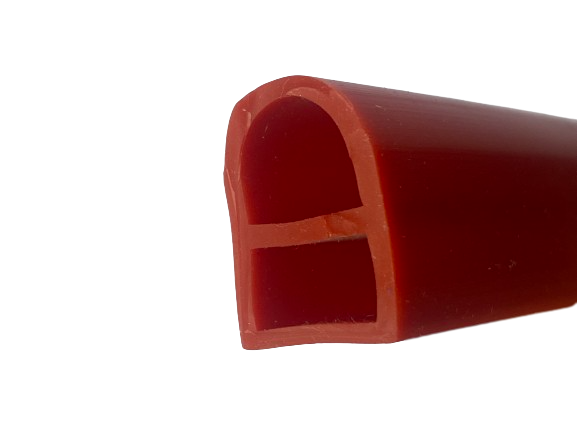

Anti-collision rubber sealing strips are flexible, durable materials designed to absorb impact and reduce the risk of damage. They are typically installed on the edges of ships and docking structures, such as piers and jetties, to provide a cushioning effect during contact. Made from high-quality rubber compounds, these strips are resistant to wear, environmental factors, and temperature fluctuations, ensuring longevity and reliability.

Manufacturing Process

The production of anti-collision rubber sealing strips involves several key steps

1. Material Selection The manufacturing process begins with the selection of high-grade rubber compounds. These materials are chosen for their resilience, durability, and ability to withstand harsh marine environments.

2. Compounding Raw rubber is mixed with various additives, such as fillers, accelerators, and curing agents, to enhance its properties. This step is crucial as it determines the performance characteristics of the final product.

3. Molding The compounded rubber is then shaped into strips using various molding techniques, such as extrusion or compression molding. This allows manufacturers to create strips of different sizes and profiles to suit specific vessel designs and docking requirements.

4. Curing After molding, the rubber undergoes a curing process (vulcanization) to enhance its strength and elasticity. This process is key to ensuring that the sealing strips can effectively absorb impacts and resist deformation over time.

ship anti-collision rubber sealing strip factories

5. Quality Control Finished products undergo rigorous testing to ensure they meet safety and performance standards. This includes flexibility tests, tensile strength tests, and environmental resistance assessments.

Applications in Maritime Industry

Anti-collision rubber sealing strips are crucial in various maritime contexts

- Maritime Transport Ships often face risks while docking or navigating narrow waterways. Installing these strips along the hull of vessels or at the edges of docking facilities minimizes the chances of serious damage during these critical maneuvers.

- Harbor Facilities Ports are bustling environments where multiple vessels operate simultaneously. Sealing strips protect piers, fenders, and other structures from impacts that can occur during berthing or due to waves and current action.

- Recreational Boating Smaller boats and yachts also benefit from the installation of anti-collision rubber sealing strips. These components provide peace of mind to boat owners, reducing the likelihood of costly repairs due to accidental collisions.

Conclusion

The production and use of ship anti-collision rubber sealing strips are integral to enhancing safety in the maritime industry. As the demand for maritime transport increases, investing in high-quality sealing strips becomes essential not only for protecting vessels but also for ensuring the safety of crew members and port infrastructure. Factories specializing in these rubber products play a pivotal role in this ecosystem, employing advanced manufacturing techniques and stringent quality control measures to deliver reliable solutions.

In summary, the importance of anti-collision rubber sealing strips cannot be overstated. They are a fundamental component in the maritime industry that contributes to safety, efficiency, and long-term sustainability. Properly manufactured and installed, these strips are key to mitigating the risks associated with maritime operations, playing a critical role in the continuing evolution of marine safety standards.