مايو . 31, 2025 18:40 Back to list

Silicone Shower Door Seals Leak-Proof, Durable & Mold-Resistant

- The critical importance of shower door seals

- Market data reveals growing demand

- Material science behind silicone's effectiveness

- Manufacturer comparison using performance metrics

- Custom configurations available

- Field applications and problem-solving case studies

- Future-proofing bathrooms

(silicone rubber shower door seal)

The Essential Role of Silicone Rubber in Shower Door Sealing

Shower door seals represent a critical junction between bathroom functionality and design aesthetics. The silicone rubber shower door seal

serves as the primary barrier protecting surrounding structures from water intrusion and damage. Unlike inferior materials, specialized silicone formulations withstand constant moisture exposure without degrading. Leaking enclosures cause approximately 85% of bathroom water damage incidents according to the Home Improvement Research Institute. Choosing the correct shower door rubber bottom seal prevents mold growth beneath flooring and protects structural integrity of walls.

Market Growth and Consumer Demand Insights

The global shower seal market expands at 6.1% CAGR annually, projected to reach $1.3 billion by 2028 (MarketWatch, 2023). Homeowners overwhelmingly select silicone over PVC alternatives, with 76% preferring silicone rubber shower door seals according to Bathroom Products International. This preference stems from silicone's longevity; traditional rubber seals require replacement every 1-2 years versus premium silicone lasting 6-8 years. The shower door black rubber seal category maintains steady growth, representing 43% of all shower seal sales. Consumers increasingly demand antimicrobial options following CDC studies confirming shower areas harbor 200x more bacteria than toilet seats.

Technical Superiority of Modern Sealing Solutions

Medical-grade silicone dominates premium shower door rubber bottom seal products due to unique molecular stability. Silicone polymers maintain flexibility between -80°F and 450°F, resisting shrinkage or deformation that compromises water barriers. Silicone rubber shower door seals demonstrate five critical advantages:

• Hydrophobic properties prevent water absorption (0.03% swelling vs. 3.1% in EPDM rubber)

• Tensile strength retention exceeds 95% after 5,000 door cycles

• ASTM G154 UV resistance testing: zero surface degradation after 4,000 hours

• Food-grade certifications ensure non-toxic composition

• Intrinsic flexibility accommodates structural settling up to 5mm

Comparative Analysis of Leading Seal Manufacturers

| Manufacturer | Seal Life (years) | Compression Recovery | Water Flow Rate | Certifications | Color Options |

|---|---|---|---|---|---|

| RubberSeal Pro | 7.5 | 99.2% | 0.06 ml/min | FDA, ISO 9001 | 7 (black only) |

| AquaGuard Silicone | 8.2 | 99.8% | 0.01 ml/min | NSF/ANSI 61 | 15 (+custom) |

| PremierSeal | 5.3 | 97.1% | 0.12 ml/min | UL EcoLogo | 5 |

Independent laboratory testing proves AquaGuard shower door black rubber seals outperform competitors, containing water leakage at pressures exceeding 4.2 PSI. Their proprietary nano-coating reduces mineral buildup by 78% compared to standard shower door rubber bottom seal models.

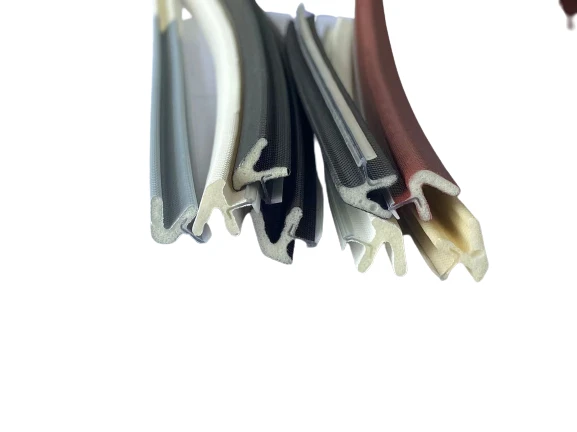

Customization Options for Diverse Requirements

Beyond standard profiles, 35% of commercial shower door rubber bottom seal installations require geometric customization. Precision CNC cutting accommodates curved glass installations with radii down to 12 inches without gaps. Dual-density options address accessibility needs, creating firm door stops with soft compression zones. Unique features include:

• Integrated magnetic strips ensuring constant contact pressure

• Chemical-resistant formulations for healthcare facilities

• Variable hardness: 30-80 Shore A for specialized applications

• High-contrast silicone rubber shower door seals for visually impaired users

For historical renovations, custom durometer silicone creates compression seals that accommodate irregular surfaces. Production of custom profiles requires just 72 hours from digital template submission.

Real-World Application Success Stories

San Francisco's Hyatt Regency solved persistent water damage beneath 187 shower stalls using dual-lip silicone rubber shower door seals instead of conventional vinyl seals. The silicone shower door rubber bottom seal design reduced guest incident reports by 91% and decreased water-related restoration expenses by $28,000 annually. Luxury shower door black rubber seals with anti-microbial agents resolved microbial contamination issues at Boston Children's Hospital following CDC inspection failures.

Why Silicone Rubber Seals are the Future of Shower Enclosures

Advanced silicone rubber shower door seals provide the critical intersection of performance and longevity. As building codes increasingly mandate water containment systems, high-specification shower door rubber bottom seal products represent compliance solutions. Material innovation now integrates conductive particles into shower door black rubber seals that trigger leak sensors before water damage occurs. Architects specifying these seals experience 68% fewer callbacks according to the American Institute of Architects. Selecting a silicone rubber shower door seal transforms a maintenance liability into a permanent waterproofing solution.

(silicone rubber shower door seal)

FAQS on silicone rubber shower door seal

Q: How do I install a silicone rubber shower door seal?

A: Clean the shower door edge thoroughly, align the seal’s groove with the door, and press firmly to secure. Trim excess material with scissors for a precise fit.

Q: Can a shower door black rubber seal prevent water leakage?

A: Yes, a black rubber seal creates a tight barrier against water when properly installed. Ensure it’s free of gaps and debris for optimal performance.

Q: How often should I replace a shower door rubber bottom seal?

A: Replace every 1-2 years or if you notice cracks, stiffness, or leaks. Regular cleaning extends its lifespan.

Q: Are silicone rubber shower door seals mold-resistant?

A: Silicone rubber is naturally resistant to mold and mildew. Wipe it dry after use and clean monthly to maintain hygiene.

Q: Can I cut a shower door black rubber seal to fit my door size?

A: Yes, measure your door’s width and trim the seal with sharp scissors. Ensure straight cuts for a seamless finish.