снеж . 10, 2024 20:27 Back to list

Custom Sealing Solutions for Gaps in Solar Photovoltaic Panels

Custom Sealing Strips for Gaps in Photovoltaic Solar Panels

As the world increasingly shifts toward sustainable energy, photovoltaic solar panels have emerged as a leading technology in harnessing solar energy. However, the efficiency of these systems can be significantly affected by small gaps and seams that can trap dust, dirt, and water, leading to reduced performance and potential long-term damage. To address these issues, custom sealing strips have become an essential component in the design and installation of solar panels, offering a practical solution to enhance their durability and effectiveness.

Importance of Sealing in Solar Panels

Solar panels are exposed to various environmental conditions, including rain, wind, dust, and temperature fluctuations. These factors can create gaps between the panel and mounting structure, leading to several concerns. First and foremost, gaps can allow moisture ingress, which may lead to corrosion of electrical components, reducing the lifespan of the panels. Additionally, dirt accumulation can hinder sunlight absorption, decreasing the panels' overall efficiency.

Sealing these gaps is, therefore, paramount. Traditional sealing methods may not adequately address the unique challenges posed by solar panels, especially considering the ever-evolving designs and sizes of these systems. This is where custom sealing strips play a critical role.

Advantages of Custom Sealing Strips

1. Tailored Fit One of the main advantages of custom sealing strips is their ability to provide a precise fit for specific solar panel configurations. Unlike standard sealing products, custom strips can be engineered to match the dimensions and profiles of individual solar panels, ensuring effective sealing without compromising performance.

2. Material Variability Custom sealing strips can be made from various materials, including elastomers, silicone, and foam, to suit different environmental conditions and performance requirements. For instance, silicone-based strips are excellent for extreme temperatures, while foam strips may offer better flexibility and cushioning.

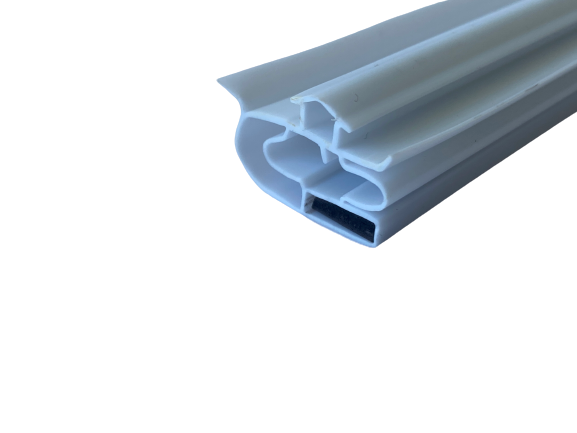

custom sealing strip for gaps in photovoltaic solar panels

3. Enhanced Durability Using high-quality materials in custom sealing strips enhances their lifespan and performance. They can resist UV radiation, extreme weather conditions, and chemical exposure, making them ideal for long-term use in outdoor environments.

4. Improved Energy Efficiency By preventing dust and moisture from entering the gaps, custom sealing strips help maintain optimal operating conditions for solar panels. This, in turn, maximizes energy output and fosters a more efficient overall solar energy system.

5. Ease of Installation Custom strips can be designed for easy application, allowing installers to quickly and efficiently seal gaps during installation. This is especially important in large-scale solar projects, where time and labor costs are critical factors.

Customization Process

The process of creating custom sealing strips begins with an assessment of the specific solar panel design and the environment in which it operates. Engineers work closely with installers and manufacturers to identify the required dimensions, materials, and performance characteristics. Prototypes may be developed and tested to ensure they meet the necessary standards before proceeding to mass production.

Conclusion

Custom sealing strips provide a vital solution to commonly overlooked issues in photovoltaic solar panel installations. By effectively sealing the gaps that can lead to performance loss and potential damage, these strips contribute significantly to the longevity and efficiency of solar energy systems. As the demand for renewable energy continues to grow, the importance of innovative solutions like custom sealing strips cannot be overstated. They not only enhance the performance of solar panels but also play a crucial role in the broader mission of achieving sustainable energy independence. Investing in tailored sealing solutions is a proactive step towards maximizing energy efficiency and ensuring the long-term success of solar projects.