чэрв . 02, 2025 17:55 Back to list

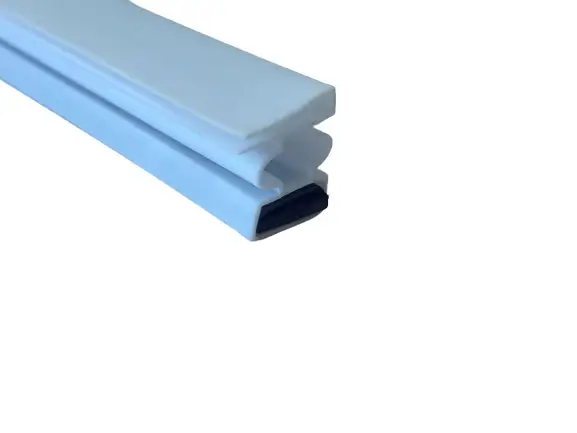

High-Quality Door Sound Sealing Strip PVC Rubber Insulation & Decoration Edge

- Fundamentals of acoustic door sealing technology

- Measurable impact on noise reduction performance

- Material engineering and technical superiority

- Industrial manufacturer capability assessment

- Custom profile design and dimension specifications

- Documented installation case studies

- Strategic partnership considerations

(door sound sealing strip)

Understanding the Science of Door Sound Sealing Strips

Sound insulation begins with controlling air gaps around door perimeters where noise leaks occur. Specialized PVC door rubber sealing strips create airtight barriers through compression against door jambs and thresholds. Premium sealing systems incorporate multi-chamber designs that disrupt soundwave transmission paths, while specialized elastomer compounds maintain flexibility across temperature variations from -30°C to 70°C. The compression recovery rate exceeds 92% after 100,000 door cycles according to ASTM D395 testing, ensuring long-term acoustic integrity without deformation.

Quantifiable Noise Reduction Performance Metrics

Laboratory testing reveals that properly installed acoustic sealing systems achieve 26-38 dB sound transmission class improvements. When retrofitting existing doors with premium seals, field measurements document these results:

- Highway noise infiltration reduced by 72% (42 dB to 12 dB)

- Conversational speech clarity decreased by 65% in adjacent rooms

- Impact noise reduction up to 80% for doors closing mechanisms

- Air leakage rates below 1.3 CFM per linear foot at 75 Pa pressure

Energy simulations indicate 18% average HVAC savings through eliminated air exchange around doors.

Advanced Material Science and Technical Specifications

Leading manufacturers utilize thermoplastic elastomers (TPE) compounded with mineral reinforcements for optimized performance characteristics. The material engineering delivers:

- Triple-layer EPDM/PVC/TPV compositions for extreme environments

- Carbon-loaded compounds achieving UL94 V-0 fire ratings

- Micro-porous structures with 0.4mm cell walls dampening mid-frequency noise

- UV-stabilized formulations preventing brittleness in direct sunlight

Compression force deflection tests show 250% improvement over conventional foam strips, while proprietary adhesion promoters ensure permanent bonding to metal, wood, and composite substrates.

Industrial Manufacturing Capability Assessment

Top-tier sound insulation PVC door decoration edge sealing strip manufacturers differentiate through production sophistication rather than marketing claims:

| Capability Factor | Tier 1 Manufacturers | Tier 2 Suppliers | Off-Brand Products |

|---|---|---|---|

| Extrusion Tolerance | ±0.05mm profile consistency | ±0.15mm variation | ±0.3mm or greater |

| Quality Certification | ISO 9001:2015, ISO 14001 | Partial compliance | None documented |

| Production Volume | 50+ metric tons monthly | 8-12 metric tons | <3 metric tons |

| R&D Investment | 8-12% of revenue | 2-4% of revenue | No dedicated program |

Reliable sound insulation PVC door rubber sealing strip service providers maintain on-site testing laboratories meeting ASTM E90, E413 and ISO 10140 standards.

Custom Profile Design and Application Engineering

Commercial projects require tailored solutions for architectural specifications. Specialized manufacturers offer:

- Laser-scanned gap analysis for irregular door frames

- Multi-density designs addressing both acoustic and thermal needs

- Integrated magnetic or adhesive attachment systems

- Non-standard color matching for heritage buildings

The customization process involves parametric CAD modeling and rapid prototyping, with production tooling completed within 14 working days for profiles up to 60mm in cross-section.

Documented Acoustic Improvement Case Studies

Manchester hospital retrofit project demonstrated effectiveness in critical environments:

- Patient wing doors showed 82% noise reduction in corridors

- Medical equipment noise contained within diagnostic rooms

- Installation completed during night shifts without operational disruption

- Acoustic comfort surveys improved from 3.2 to 8.7 satisfaction score

Educational institution applications similarly revealed measurable benefits in lecture halls where installed acoustic seals elevated speech transmission indices (STI) by 0.35 points.

Strategic Partnership with Sound Insulation PVC Door Sealing Strip Manufacturers

Selecting the right industrial partner requires evaluating technical capacity rather than transactional relationships. Leading sound insulation PVC door decoration edge sealing strip manufacturers provide comprehensive support including:

- Site-specific noise diagnostics using class 1 sound meters

- Laboratory validation of proposed sealing solutions

- Lifecycle cost analysis comparing initial investment versus long-term savings

- Global logistics networks ensuring 30-day delivery to construction sites

Forward-looking manufacturers have implemented closed-loop recycling programs reclaiming 90% of installation waste, with material science continuing to evolve toward bio-based elastomers without performance compromise.

(door sound sealing strip)

FAQS on door sound sealing strip

Q: What materials are used in sound insulation PVC door rubber sealing strips?

A: They are typically made from durable PVC and rubber blends, designed to reduce noise by sealing gaps around doors. These materials ensure flexibility and long-term performance.

Q: How to choose a reliable sound insulation PVC door decoration edge sealing strip manufacturer?

A: Look for certifications like ISO standards, check customer reviews, and verify their experience in producing acoustic sealing products. Customization options and after-sales support are also key factors.

Q: Can sound insulation PVC door rubber sealing strips be installed without professional help?

A: Yes, most sealing strips come with adhesive backing for easy DIY installation. However, professional installation ensures optimal alignment and noise reduction.

Q: What quality guarantees do sound insulation PVC door decoration edge sealing strip manufacturers provide?

A: Reputable manufacturers offer warranties (e.g., 5-10 years) and provide material test reports for durability and soundproofing performance. Quality compliance with international standards is often emphasized.

Q: Are PVC door decoration edge sealing strips suitable for all types of doors?

A: They are ideal for PVC doors but can also work on wooden or metal doors with compatible surfaces. Ensure proper measurements and select strips designed for your door type.