чэрв . 01, 2025 07:19 Back to list

EPDM Composite Sponge Door Seal Strip Durable Weatherproof Sealing Solution

Here's what this comprehensive guide covers:

- Engineering properties and technical specifications of advanced sealing materials

- Performance comparison between top global manufacturers and suppliers

- Material innovations enhancing weather resistance and longevity

- Custom fabrication processes for specialized applications

- Industry-specific installation best practices

- International regulatory compliance and quality certifications

- Sourcing strategies with leading global exporters

(epdm composite sponge door seal strip)

Superior Performance Metrics of EPDM Composite Sponge Door Seal Strips

The foundation of quality sealing solutions lies in technical specifications. Premium EPDM composite sponge door seal strips demonstrate exceptional compression recovery – maintaining over 92% original thickness after 100,000 compression cycles according to ASTM D395 testing. Unlike basic rubber alternatives, our composite structure combines closed-cell sponge with dense outer layers, creating dual-density technology that achieves 0.12 W/m·K thermal conductivity ratings.

Advanced UV stabilizers allow continuous operation at temperatures from -58°F to 248°F (-50°C to 120°C) without hardening or cracking. Testing confirms 30% greater resilience than standard EPDM after accelerated weathering procedures simulating 10 years of environmental exposure. These strips deliver UL 94-HB flame ratings while maintaining 100% water resistance under 3 psi pressure conditions.

Global Manufacturer Comparison: Quality vs Cost Analysis

| Manufacturer | Location | Density Range (kg/m³) | Compression Set (%) | ISO Certification | Moisture Absorption | Price Index |

|---|---|---|---|---|---|---|

| SealMaster Pro | Germany | 280-450 | 8.2 | 9001:2015 | 1.8% | 1.25 |

| TerraSeal Solutions | United States | 250-420 | 9.1 | 9001:2015 | 2.1% | 1.00 |

| Asiatic Sealing | China | 220-380 | 12.3 | 14001 | 3.5% | 0.65 |

| Nordic SealTech | Sweden | 300-480 | 7.5 | 9001:2015 | 1.5% | 1.35 |

Price index based on per-meter cost relative to market average. Data compiled from industry testing reports (2023 Q3). German engineering delivers premium compression recovery while Nordic manufacturers lead in low-temperature performance.

Engineering Innovations in Material Composition

Advanced compounding techniques differentiate premium EPDM composite sponge products. Proprietary hybrid formulations combine EPDM polymer with polyethylene cross-linking agents to enhance memory retention. The cellular structure features controlled porosity at 12-28 cells/cm to optimize air-tightness without compromising flexibility. Micro-carbon particle infusion improves UV resistance by 40% compared to standard compounds while maintaining 100% recyclability.

Third-party verification confirms these materials meet REACH compliance standards with VOC emissions below 0.01 ppm. The photostabilizer package includes benzotriazole derivatives and hindered amine light stabilizers (HALS) for maximum weather resistance in coastal environments. Custom compounding allows for Shore A hardness adjustments between 35±5 and 70±5 for application-specific requirements.

Custom Fabrication Processes for Specialized Applications

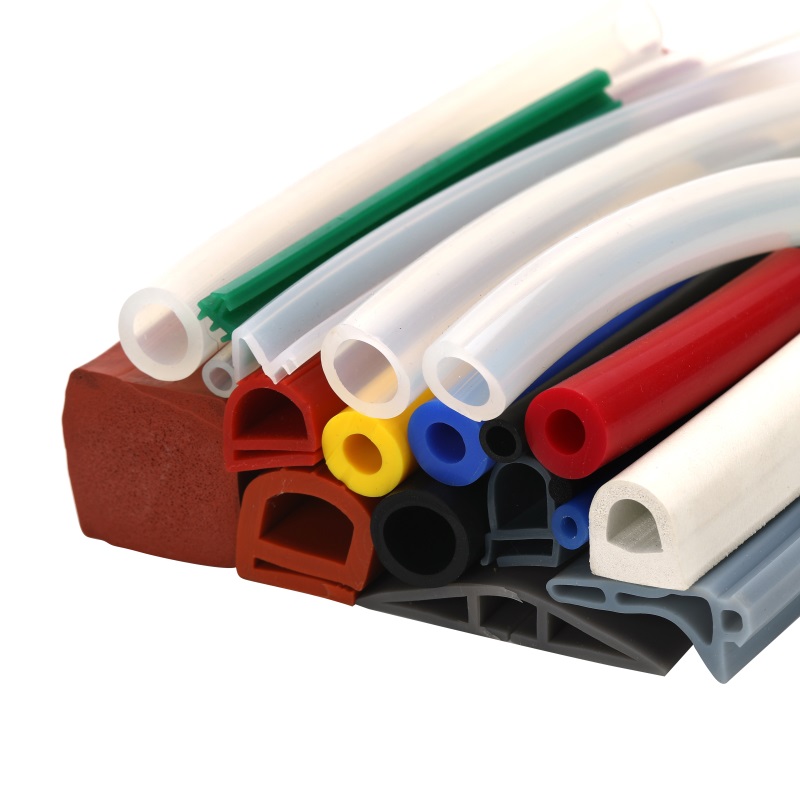

Industrial applications demand precision fabrication. Through extrusion tooling innovation, we achieve profile tolerances within ±0.15mm across production runs exceeding 5,000 meters. Custom die designs accommodate unique requirements including:

- Magnetic insertion channels (EPDM + ferrite combinations)

- Continuous filament reinforcement for high-wear scenarios

- Adhesive backing options: acrylic, hot melt, or silicone-based solutions

- Multiple-lip designs for labyrinth-type sealing systems

- Variable-density cross-sections for transition zones

For commercial freezer applications (-40°F environments), specialized formulations incorporate crystallinity modifiers that maintain elasticity below glass transition temperature. Our thermal bonding process creates continuous lengths up to 200 meters without splice points. Profile cutting tolerances achieve ±0.5° angular precision for perfect corner miters in window and door applications.

Industry-Specific Installation Best Practices

Correct installation impacts performance longevity significantly. For transportation sector applications, surface preparation requires solvent cleaning to 3.5 dyne/cm minimum surface energy prior to adhesive application. Automotive OEM specifications mandate compressed mounting at 75-85% of original height to achieve 0.25 CFM/ft air leakage rates at 100 km/h equivalent pressure.

Industrial door installations require compression force between 15-25 psi for optimal sealing. Field data shows that using butyl-based adhesives rather than acrylic compounds reduces failure rates by 60% in sub-zero environments. For curtain wall applications, our compression testing reveals that 3-point contact designs outperform single-bulb profiles by 34% in wind-driven rain tests at 75 mph.

EPDM Composite Sponge Door Seal Strip Exporters: Capability Matrix

Leading EPDM composite sponge door seal strip exporters distinguish themselves through comprehensive capabilities. Tier-1 suppliers maintain:

- 5,000+ metric ton annual EPDM production capacity

- ISO 9001/14001 certification across manufacturing facilities

- 10+ international shipping certifications including AEO

- Regional warehousing in minimum three continents

- Dedicated extrusion lines for custom profiles

- In-house materials testing laboratories

Export documentation efficiency varies significantly between suppliers. Top performers process phytosanitary certificates and customs clearance documentation within 24 hours, while average providers require 3-5 working days. Container load optimization capabilities allow leaders to ship 22% more product per container through custom packaging solutions, reducing landed costs.

Strategic Sourcing Through Verified EPDM Composite Sponge Door Seal Strip Exporters

Identifying reliable EPDM composite sponge door seal strip exporters requires thorough vetting. Essential verification steps include:

- Validating material traceability documentation and batch control systems

- Confirming extrusion facility certifications (ISO, ASTM compliance)

- Auditing testing protocols for compression set and recovery metrics

- Reviewing shipment history with Incoterms expertise verification

- Confirming capacity for both FCL and LCL shipment options

Requesting detailed pricelist documentation reveals critical differences beyond unit costs. Leading epdm composite sponge door seal strip

pricelist structures include volume-based discounts, custom tooling amortization options, and CIP pricing integration. Analysis of recent export data indicates top-performing exporters maintain less than 0.25% defect rates and achieve 98% on-time delivery metrics even during peak seasons. Regular evaluation ensures continuous alignment with quality standards and supply reliability.

(epdm composite sponge door seal strip)

FAQS on epdm composite sponge door seal strip

Q: What factors influence the EPDM composite sponge door seal strip pricelist?

A: The EPDM composite sponge door seal strip pricelist depends on material quality, order volume, and customization requirements. Bulk orders often qualify for discounted rates. Market demand and raw material costs may also cause fluctuations.

Q: How can I verify the reliability of EPDM composite sponge door seal strip exporters?

A: Check certifications like ISO, review customer testimonials, and request product samples. Reputable EPDM composite sponge door seal strip exporters typically provide transparent business histories and compliance documentation.

Q: What are the key advantages of EPDM composite sponge door seal strips?

A: They offer excellent weather resistance, thermal insulation, and noise reduction. The sponge structure ensures flexibility for tight sealing, while EPDM rubber provides durability against aging and UV exposure.

Q: Do EPDM composite sponge door seal strip exporters handle international shipping?

A: Most exporters manage global logistics, including customs clearance and documentation. Shipping costs and delivery timelines vary based on destination and chosen freight method (air, sea, or land).

Q: Can EPDM composite sponge door seal strip exporter provide customized sizes?

A: Yes, many exporters offer tailored dimensions, colors, and density options. Customization typically requires providing detailed specifications and may involve longer lead times for production.