Верас . 21, 2024 17:58 Back to list

epdm oil tank gasket company

The Importance of EPDM Oil Tank Gaskets in Industrial Applications

In the realm of industrial applications, the integrity of equipment is paramount to ensure safety, efficiency, and longevity. One often overlooked but crucial component in this regard is the gasket, particularly those made from EPDM (Ethylene Propylene Diene Monomer) rubber. EPDM gaskets are widely used in oil tanks, playing a significant role in preventing leaks, maintaining pressure, and ensuring reliable performance under various conditions.

What is EPDM?

EPDM is a type of synthetic rubber noted for its exceptional resistance to heat, ozone, and weathering. This makes it an excellent choice for applications that require durability and longevity. Unlike traditional rubber, EPDM does not degrade as quickly when exposed to harsh environmental conditions, making it ideal for outdoor installations or areas subject to temperature fluctuations. Its chemical resistance also enables it to handle various hydrocarbons, making it a preferred material for oil tank gaskets.

The Role of Gaskets in Oil Tanks

Gaskets serve as seals between two or more surfaces, preventing the escape of fluids or gases. In oil tanks, the gaskets are critical components that help contain the fluids and maintain the integrity of the tank system. Any failure in the gasket can lead to leaks, resulting in environmental hazards, safety risks, and financial losses. Therefore, the quality of gaskets must not be compromised.

Benefits of Using EPDM Gaskets

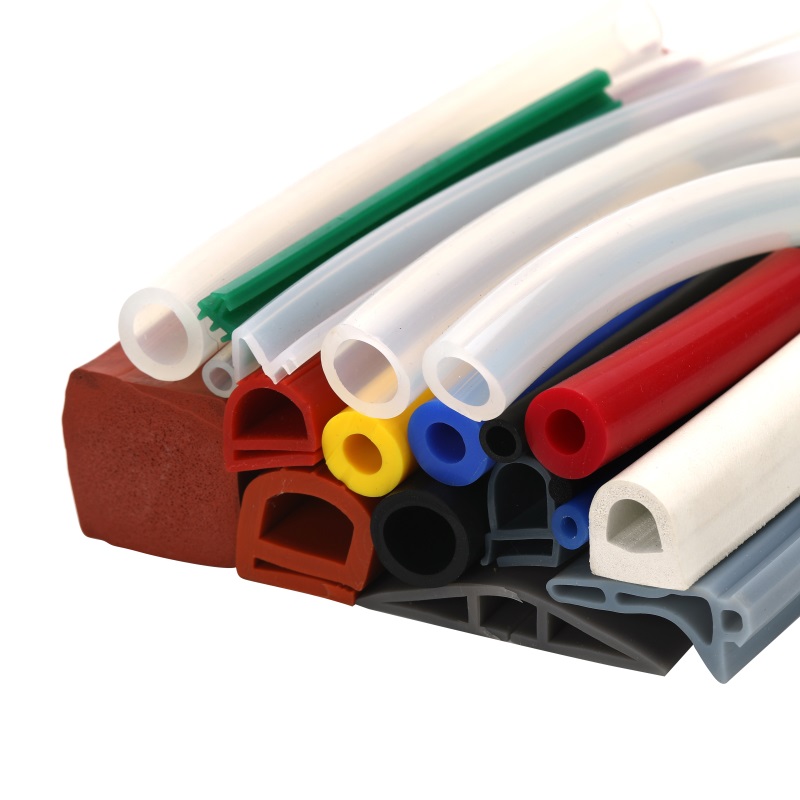

epdm oil tank gasket company

2. Temperature Stability With the ability to perform well in a wide temperature range, EPDM gaskets can maintain their sealing properties even in extreme heat or cold. This stability is crucial for oil tanks that may experience temperature fluctuations due to external weather conditions or the heating of stored products.

3. Durability The durability of EPDM results in longer-lasting gaskets that require less frequent replacement. This not only saves money in maintenance costs but also minimizes downtime, enhancing overall productivity.

4. Environmentally Friendly As industries become more conscious of their environmental impact, EPDM offers a more sustainable gasket option compared to traditional materials. Its long life and resistance to degradation mean less waste and fewer replacements over time.

Choosing the Right EPDM Gasket Company

When sourcing EPDM oil tank gaskets, it is essential to partner with a reputable gasket company. Look for manufacturers that specialize in custom gasket solutions and use high-quality materials. Certifications and industry standards should also be considered to ensure that the gaskets meet the necessary safety and performance requirements.

Conclusion

In conclusion, EPDM oil tank gaskets are vital components in industrial settings, ensuring the safe and efficient operation of storage systems. Their unique properties make them particularly suited for handling the challenges posed by oil and other chemicals. By choosing high-quality EPDM gaskets from a reliable supplier, industries can bolster their operational safety and sustainability while reducing costs associated with equipment failure and maintenance. As demand for safer and more efficient industrial solutions continues to grow, EPDM gaskets stand out as a trusted choice for oil tank applications.