Ліст . 24, 2024 05:55 Back to list

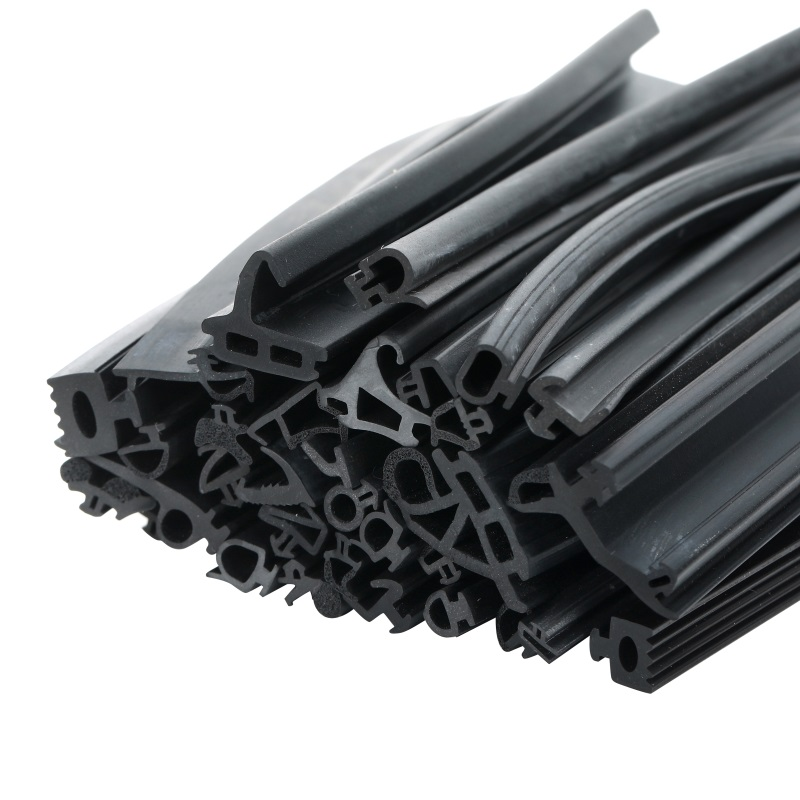

epdm reinforced rubber sheet

The Versatility of EPDM Reinforced Rubber Sheets

EPDM, or Ethylene Propylene Diene Monomer, is a type of synthetic rubber known for its remarkable resilience and durability. One of the most useful forms of EPDM is the reinforced rubber sheet, which has become a staple in various industrial applications, thanks to its impressive properties. This article explores the features, benefits, and applications of EPDM reinforced rubber sheets.

Understanding EPDM Rubber

EPDM rubber is highly regarded for its excellent resistance to weather, ozone, heat, and aging. Its unique molecular structure allows it to maintain flexibility and strength even in extreme temperatures, ranging from -40°F to over 250°F. The addition of reinforcement—typically in the form of fabric or other materials—enhances its mechanical strength, making it suitable for high-stress environments.

Key Properties of EPDM Reinforced Rubber Sheets

1. Weather Resistance One of the standout features of EPDM reinforced rubber sheets is their ability to withstand harsh weather conditions. They don’t suffer from cracking or degrading when exposed to UV rays or ozone, which makes them ideal for outdoor applications.

2. Enhanced Durability The reinforcement added to EPDM sheets provides improved tensile strength and durability. They can endure mechanical stress, making them perfect for uses involving heavy foot traffic or equipment.

3. Flexibility Despite their strength, EPDM reinforced rubber sheets retain significant flexibility, allowing them to be molded and cut to fit various shapes and sizes. This adaptability makes them suitable for a range of custom applications.

4. Chemical Resistance EPDM has a good resistance to various chemicals, including acids and alkalis, which extends its usability in industrial settings where exposure to harsh substances is common.

5. Noise Reduction Reinforced rubber sheets are also effective in dampening sound, making them a popular choice for applications requiring noise reduction, such as flooring in commercial and industrial environments.

epdm reinforced rubber sheet

Applications of EPDM Reinforced Rubber Sheets

EPDM reinforced rubber sheets are employed in a multitude of industries due to their versatile properties. Here are some notable applications

1. Construction These sheets are widely used as roofing membranes. Their weather-resistant nature ensures longevity and protection against leaks, making them a reliable choice for flat roofs. They are also used for sealing joints and gaps in building structures.

2. Automotive In the automotive industry, EPDM reinforced rubber sheets are used in vehicle door seals, window gaskets, and under-hood component protection. Their resistance to extreme temperatures and chemicals makes them well-suited for these applications.

3. Manufacturing Many manufacturing plants utilize EPDM sheets as padding or protective surfaces on equipment and machinery to prevent damage and reduce vibration.

4. Marine Applications The marine industry benefits from EPDM’s resistance to water and salt exposure. Reinforced sheets are used in boat seals, linings, and as gaskets, ensuring long-lasting performance in a challenging environment.

5. Flooring Solutions The noise-dampening properties of EPDM reinforced rubber sheets make them a popular choice for gym floors, playgrounds, and commercial spaces where noise reduction is essential.

Conclusion

In summary, EPDM reinforced rubber sheets epitomize versatility in material science. Their exceptional properties, combined with the ability to be tailored for specific applications, make them indispensable in various industries. As technology progresses and industries evolve, the demand for these resilient sheets is likely to grow, further solidifying their role as a vital component in modern manufacturing, construction, and design. Whether it’s protecting a building from the elements or cushioning machinery on a factory floor, EPDM reinforced rubber sheets are a reliable choice that continues to prove its worth across diverse applications.