снеж . 14, 2024 02:02 Back to list

Affordable EPDM Rubber Sheet Pricing and Quality Options Available Online

Understanding the Dynamics of EPDM Rubber Sheet Pricing

EPDM (Ethylene Propylene Diene Monomer) rubber is a highly durable synthetic rubber that has become a popular choice for a variety of applications, thanks to its excellent weather resistance, flexibility, and overall durability. As businesses and individuals look to procure EPDM rubber sheets, understanding the factors that influence the pricing of these materials is essential for making informed purchasing decisions.

Factors Influencing EPDM Rubber Sheet Prices

1. Raw Material Costs The primary factor that impacts the price of EPDM rubber sheets is the cost of the raw materials involved in its production. Fluctuations in the prices of ethylene and propylene—which are derived from petroleum—can significantly affect the cost structure. When oil prices increase, the cost of EPDM can also rise, impacting buyers.

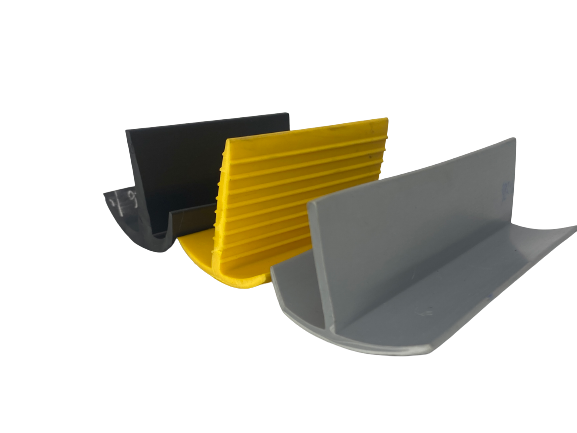

2. Thickness and Specifications EPDM rubber sheets come in various thicknesses, grades, and specifications. For instance, thicker sheets typically cost more due to the additional material required for production. Furthermore, specialized formulations that enhance specific properties—such as flame retardance, increased tensile strength, or added UV resistance—can also lead to higher prices.

Understanding the Dynamics of EPDM Rubber Sheet Pricing

4. Customization and Order Quantity Many businesses require customized EPDM rubber sheets tailored to specific applications. Customization can include unique dimensions, colors, or additional coatings. These tailored specifications can increase the price per sheet. Additionally, order quantity plays a significant role; larger bulk orders often result in discounts, reducing the price per unit.

epdm rubber sheet quotes

5. Geographic Location Location can also influence pricing due to shipping costs, local demand, and availability. For example, customers located closer to manufacturing facilities may incur lower shipping rates, while those farther away might pay higher prices reflective of shipping costs. Furthermore, regional market dynamics and demand fluctuations can also lead to price variations.

6. Vendor Relations and Industry Competition The competitive landscape within the rubber sheet market can lead to price adjustments. When vendors compete for market share, they may lower prices or offer promotions to attract customers. Establishing strong relationships with suppliers can also lead to better pricing and terms over time.

Conclusion

When considering the purchase of EPDM rubber sheets, it’s vital to evaluate these influencing factors to understand the pricing dynamics. Customers should conduct thorough market research, comparing quotes from various suppliers to ensure they are getting the best value for their investment. Additionally, understanding the specific requirements of their applications will help businesses select the right quality and specifications without overspending.

By considering elements such as raw material costs, customization needs, production techniques, and geographical factors, buyers can navigate the complexities of pricing in the EPDM rubber sheet market. This informed approach will lead to more strategic purchasing decisions, ultimately benefiting both their immediate needs and long-term project goals.

As the demand for high-performance materials continues to rise in various industries, understanding the nuances behind pricing will enable buyers to make sound decisions that not only meet their operational requirements but also align with their budgetary constraints. With the right information and strategies in place, acquiring EPDM rubber sheets can be a straightforward component of any project requiring reliable and durable materials.