лют . 11, 2025 00:44 Back to list

3m multi-function silicone sealing strip

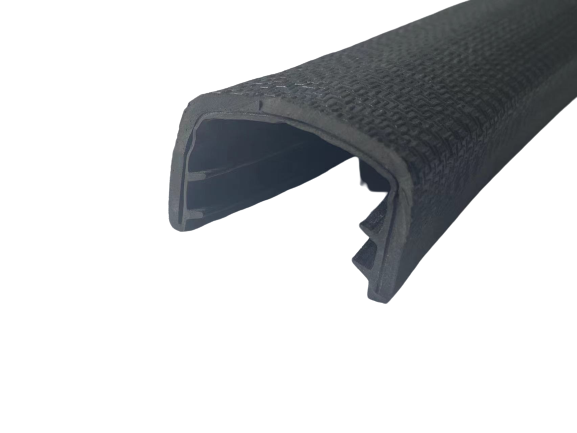

In the dynamic and demanding realm of marine engineering, the significance of high-quality OEM marine sealing strips cannot be overstated. These pivotal components ensure the impeccable performance and longevity of marine vessels by providing the crucial barrier against water ingress, corrosion, and environmental damage. Leveraging years of hands-on experience within the maritime industry, it has been evident that the right sealing solution can dramatically enhance the efficiency and reliability of marine operations.

Building trust with customers transcends beyond product quality and extends to after-sales service. Providing comprehensive installation guides, ongoing technical support, and maintenance advice demonstrates a commitment to ensuring that customers not only receive a product but a holistic solution tailored to their unique marine challenges. Testimonials and case studies illustrating successful applications of OEM marine sealing strips across various vessel types amplify credibility and assure potential clients of consistent reliability. Moreover, an authoritative online presence underscores the significance of these sealing solutions by educating stakeholders—engineers, procurement specialists, and vessel operators—on the critical role that effective sealing plays in maritime safety and efficiency. Rich content fueled by years of maritime expertise, covering installation procedures, troubleshooting tips, and technological advancements, helps bridge potential knowledge gaps while emphasizing the importance of utilizing certified OEM products. In conclusion, drawing from a wealth of professional experience, OEM marine sealing strips are far more than tangible goods; they embody the commitment to maritime excellence and safety. Embracing a comprehensive approach that combines engineering expertise, industry authority, and unwavering customer support not only fortifies the vessel's defenses against the elements but also fortifies the provider’s standing in the marketplace.

Building trust with customers transcends beyond product quality and extends to after-sales service. Providing comprehensive installation guides, ongoing technical support, and maintenance advice demonstrates a commitment to ensuring that customers not only receive a product but a holistic solution tailored to their unique marine challenges. Testimonials and case studies illustrating successful applications of OEM marine sealing strips across various vessel types amplify credibility and assure potential clients of consistent reliability. Moreover, an authoritative online presence underscores the significance of these sealing solutions by educating stakeholders—engineers, procurement specialists, and vessel operators—on the critical role that effective sealing plays in maritime safety and efficiency. Rich content fueled by years of maritime expertise, covering installation procedures, troubleshooting tips, and technological advancements, helps bridge potential knowledge gaps while emphasizing the importance of utilizing certified OEM products. In conclusion, drawing from a wealth of professional experience, OEM marine sealing strips are far more than tangible goods; they embody the commitment to maritime excellence and safety. Embracing a comprehensive approach that combines engineering expertise, industry authority, and unwavering customer support not only fortifies the vessel's defenses against the elements but also fortifies the provider’s standing in the marketplace.