снеж . 04, 2024 21:57 Back to list

self adhesive door bottom plug sealing strip factories

Understanding Self-Adhesive Door Bottom Plug Sealing Strip Factories

In today’s modern world, energy efficiency and noise reduction have become critical considerations for both residential and commercial properties. One popular solution to address these concerns is the use of self-adhesive door bottom plug sealing strips. These products serve as effective barriers against drafts, moisture, and noise, significantly improving indoor comfort. This article delves into the factories that manufacture these essential sealing strips, exploring their functions, materials, manufacturing processes, and benefits.

The Function of Door Bottom Sealing Strips

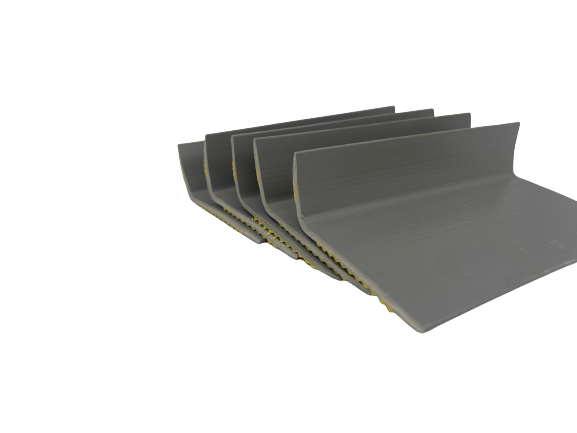

Door bottom sealing strips are designed to close the gap between the bottom of a door and the floor. This gap can lead to heat loss, increased energy bills, and infiltration of dust, dirt, and pests. Self-adhesive strips are particularly user-friendly as they can be easily attached to the door without the need for additional hardware or complicated installation processes. They are available in various sizes and materials, catering to diverse needs and preferences.

Materials Used in Manufacturing

The materials used in the production of self-adhesive door bottom plug sealing strips vary widely. Common materials include

1. Rubber This material is favored for its durability and flexibility. Rubber strips effectively seal gaps while retaining their shape over time.

2. Foam Foam sealing strips offer excellent thermal insulation and are lightweight, making them easy to handle and install.

3. Vinyl Vinyl strips are moisture-resistant and can withstand various weather conditions, making them ideal for exterior doors.

4. Plastic Some sealing strips are made from high-quality plastics, which can offer good insulation properties as well as resistance to wear and tear.

In addition to these core materials, manufacturers often incorporate adhesives that are specially formulated for strong, lasting adhesion. The choice of materials not only affects the performance but also the pricing and availability of the sealing strips in the market.

The Manufacturing Process

The production of self-adhesive door bottom plug sealing strips involves several steps

self adhesive door bottom plug sealing strip factories

1. Material Selection Factories begin by sourcing high-quality raw materials. The choice of materials heavily influences the final product’s effectiveness, durability, and suitability for different applications.

2. Cutting Raw materials are cut into specific lengths and shapes. This process requires precision to ensure that each piece fits standard door sizes.

3. Adhesive Application A strong adhesive layer is applied to one side of the sealing strip. Advanced technologies are often employed to ensure that the adhesive adheres properly and offers long-lasting performance.

4. Quality Control Rigorous testing is conducted throughout the manufacturing process. Factories must ensure that the sealing strips meet industry standards for quality, effectiveness, and durability.

5. Packaging and Distribution Once the sealing strips are approved, they are packaged for distribution. Manufacturers aim to present their products attractively while ensuring they are protected during transit.

The Benefits of Self-Adhesive Door Bottom Sealing Strips

1. Energy Efficiency By sealing gaps, these strips can significantly reduce heating and cooling costs. They help maintain a consistent indoor temperature, making homes and offices more energy-efficient.

2. Noise Reduction Self-adhesive sealing strips also aid in minimizing sound transmission between rooms or from outside. This feature is especially valuable in urban settings where noise pollution can be a concern.

3. Ease of Installation The self-adhesive feature means that anyone can install these strips quickly and easily, without requiring professional help or tools.

4. Versatility These sealing strips can be applied to various door types, including wooden, metal, and glass doors, making them a versatile choice for any property.

5. Cost-Effective Solution Investing in self-adhesive sealing strips can result in substantial savings, not only in energy bills but also in potential repairs caused by water damage or pests.

Conclusion

Self-adhesive door bottom plug sealing strips represent a simple yet effective solution to issues related to air leaks, noise, and moisture. The factories that produce these strips utilize state-of-the-art technology and high-quality materials to ensure that consumers receive the best products available. By understanding the manufacturing processes and benefits of these sealing strips, property owners can make informed decisions that enhance their comfort and energy efficiency. With their range of advantages and ease of use, self-adhesive sealing strips are certainly a valuable investment for any property.