снеж . 04, 2024 14:36 Back to list

PVC Seal Strip Manufacturers for Shower Doors and Related Accessories

The Essential Role of PVC Seal Strips in Shower Door Factories

In the realm of bathroom fixtures, shower doors are an essential component that combines functionality with aesthetic appeal. Among the various parts that contribute to the efficiency and effectiveness of shower doors, PVC seal strips play a pivotal role. This article will delve into the significance of PVC seal strips, explore their manufacturing process in factories, and highlight their contribution to the overall integrity and user experience of shower doors.

Understanding PVC Seal Strips

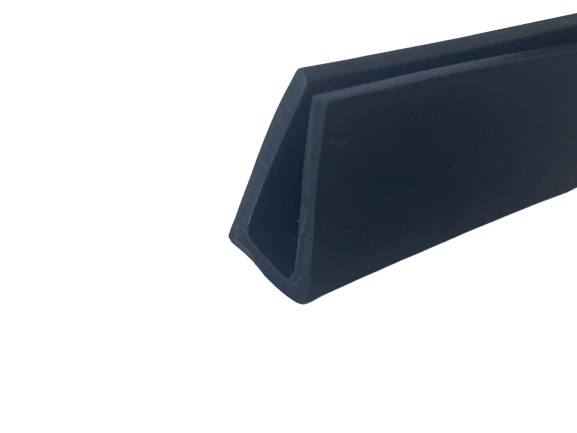

Polyvinyl Chloride (PVC) seal strips are flexible, durable, and water-resistant components used to create a secure seal between shower doors and the walls or thresholds. They prevent water leakage, keeping bathrooms dry and safe from moisture-related issues such as mold and mildew. Moreover, these seal strips enhance the thermal insulation of shower enclosures, ensuring a comfortable showering experience.

The Manufacturing Process in Shower Door Factories

The process of manufacturing PVC seal strips in shower door factories is both intricate and finely tuned

. It typically involves several stages, including material selection, extrusion, shaping, and quality control.1. Material Selection The quality of the PVC used is critical, as it directly affects the durability and performance of the seal strips. Manufacturers select high-grade PVC that can withstand exposure to moisture and temperatures typically found in bathrooms.

2. Extrusion In this phase, the selected PVC material is heated until it becomes malleable, allowing it to be shaped into strips. Once the PVC reaches the desired consistency, it is forced through a die that shapes it into the required profile for the seal strips. This method allows for mass production of uniform strips with particular dimensions.

shower door pvc seal strip factories

3. Shaping and Cutting After extrusion, the long strips are cooled and cut to specific lengths based on the design requirements of the shower doors they will serve. The shaping process may also include the addition of specific grooves or features that enhance the sealing capabilities of the strips.

4. Quality Control To ensure that the PVC seal strips meet industry standards and customer expectations, rigorous quality control measures are implemented. This includes inspecting the strips for defects, measuring dimensions, and conducting performance tests to ensure longevity and effectiveness in real-world conditions.

5. Packaging and Distribution Once the seal strips pass quality checks, they are packaged for distribution. Factories often collaborate with shower door manufacturers, providing these components as part of supply agreements that ensure timely and efficient delivery.

The Impact of Quality Seal Strips on User Experience

The importance of high-quality PVC seal strips cannot be overstated. Poorly manufactured seal strips can lead to water leaks, which not only cause damage to the bathroom but also create a slippery hazard for users. Conversely, high-quality seal strips ensure that water remains contained within the shower enclosure, providing peace of mind and safeguarding the integrity of the surrounding area.

Moreover, well-designed PVC seal strips can improve the overall look of shower doors. They can be available in various colors and finishes, allowing manufacturers to offer customizable options that align with diverse bathroom aesthetics. This aspect highlights the fact that functionality and design do not have to be mutually exclusive; rather, they can work in harmony to create products that satisfy consumer demands.

Conclusion

In summary, the role of PVC seal strips in shower door factories is crucial for ensuring the effectiveness, durability, and aesthetic appeal of shower enclosures. The meticulous manufacturing process that involves selecting high-quality materials, extrusion, shaping, and stringent quality control serves to produce seal strips that enhance the user experience and maintain bathroom safety. As bathroom fixtures continue to evolve, the significance of reliable and effective components such as PVC seal strips will remain paramount in meeting the needs of consumers and maintaining high standards in shower door manufacturing.