ডিসে. . 14, 2024 00:06 Back to list

Effective Solutions with Adhesive Sealing Strips for Various Applications and Needs

The Importance of Adhesive Sealing Strips in Modern Applications

In the realm of packaging, construction, and manufacturing, adhesive sealing strips have emerged as an essential tool for ensuring efficiency, durability, and safety. These strips, which consist of a layer of adhesive coated on one or both sides, serve multiple purposes and can be found in a variety of applications. This article delves into the significance of adhesive sealing strips, their composition, various types, and the benefits they offer.

What Are Adhesive Sealing Strips?

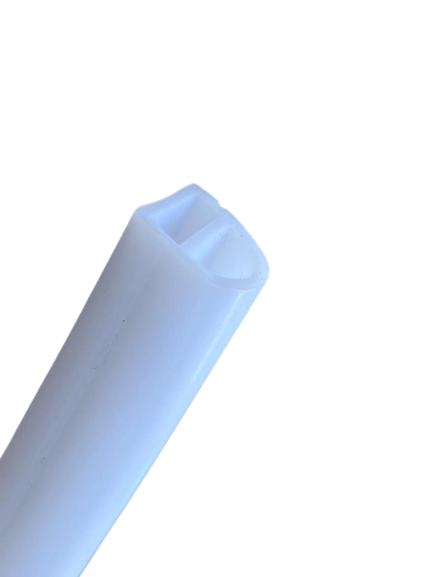

Adhesive sealing strips are manufactured from materials such as foam, rubber, or even plastic, and they come pre-coated with a special adhesive that provides a strong bond upon application. They are often used to create airtight and watertight seals, which are critical in safeguarding products from environmental factors and contamination. The versatility of adhesive sealing strips is one of the reasons they have become a staple in various industries.

Composition and Types

The composition of adhesive sealing strips can vary widely depending on the specific application requirements. Common materials include

1. Foam Often used for insulation and cushioning, foam sealing strips can absorb impact and provide an effective barrier against air and moisture. 2. Rubber Known for its elasticity and durability, rubber sealing strips are ideal for applications requiring flexibility and a robust seal.

3. Plastic Depending on the type, plastic adhesive strips can provide varying degrees of sealing capability and are often used in lightweight applications.

Adhesive sealing strips also come in different forms to cater to specific needs, including

- Double-sided strips These are particularly useful for mounting purposes, as they stick to both surfaces, providing a strong bond without the need for mechanical fasteners. - Single-sided strips Typically applied to one surface, these strips are ideal for sealing doors, windows, and gaps around appliances.

- Custom shapes Manufacturers often create tailored solutions to meet unique sealing challenges in specialized industries.

adhesive sealing strip

Benefits of Using Adhesive Sealing Strips

The advantages of using adhesive sealing strips are manifold, making them an attractive solution for various industries

1. Ease of Application One of the most significant benefits is their straightforward application process. Unlike traditional sealing methods that may require tools, adhesive strips can be applied quickly and efficiently, reducing labor time and costs.

2. Time and Cost Efficiency By eliminating the need for complex installation and the associated labor costs, adhesive sealing strips contribute to lower overall project expenses. Their quick application means faster turnaround times for products.

3. Versatility These strips can be used in multiple sectors, including automotive, electronics, construction, packaging, and even healthcare. Their adaptability makes them a go-to solution for diverse sealing needs.

4. Durability Many adhesive sealing strips are designed to withstand extreme temperatures, moisture, and other environmental factors. This resilience ensures long-lasting performance, reducing the need for frequent replacements.

5. Environmental Protection Proper sealing can significantly improve energy efficiency and reduce carbon footprints by preventing air leaks and moisture ingress, which can contribute to energy loss in buildings and vehicles.

6. Safety and Hygiene In industries like food processing and healthcare, adhesive sealing strips help maintain cleanliness and protect products from contamination, thereby ensuring safety for consumers.

Conclusion

Adhesive sealing strips are more than just a simple adhesive product; they play a critical role in enhancing the functionality and reliability of various applications across multiple industries. Their ease of use, versatility, and cost-effectiveness make them indispensable tools in modern manufacturing, construction, and packaging processes. As technology advances, the development of innovative adhesive sealing solutions will likely continue, further solidifying their place as essential components in numerous applications. Whether for sealing windows, packaging products, or ensuring the integrity of sensitive equipment, adhesive sealing strips are here to stay, contributing to safer, more efficient, and sustainable operations across the globe.

Next:

Prev: