ডিসে. . 02, 2024 07:48 Back to list

car window rubber seal factories

The Importance of Car Window Rubber Seal Factories in Automotive Manufacturing

In the automotive industry, attention to detail is paramount, and one of the crucial elements that contribute to the overall quality of a vehicle is its window seal. Car window rubber seals are essential components that ensure the structural integrity of a vehicle's windows, providing not only aesthetic appeal but also functional benefits such as noise reduction, weatherproofing, and security. This is where car window rubber seal factories come into play, playing a vital role in the manufacturing and supply chain of automotive components.

Manufacturing Process

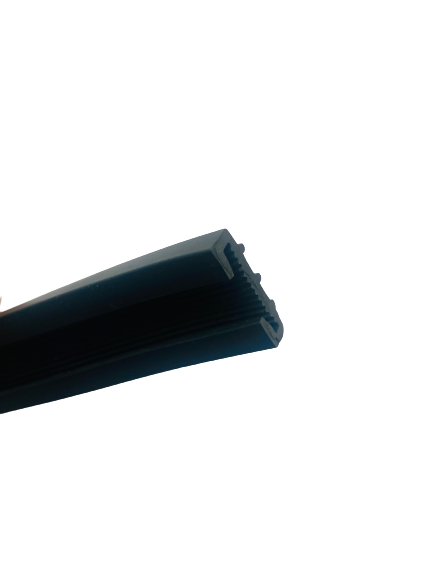

Car window rubber seal factories employ sophisticated manufacturing techniques to produce seals that meet stringent industry standards. These factories utilize advanced machinery and technology to extrude, mold, and cut rubber products to precise specifications. The process begins with the selection of high-quality raw materials, including synthetic rubber compounds that offer durability and resilience. These materials are then blended with various additives to enhance their properties, ensuring that the final product can withstand different weather conditions, resist UV degradation, and maintain flexibility over time.

Once the raw materials are prepared, they are subjected to a series of processes such as extrusion and molding. Extrusion involves forcing the rubber mixture through a die to create long, continuous lengths of seal, while molding involves shaping the rubber into specific profiles. Afterward, products undergo rigorous quality control tests to verify their performance, ensuring that they can effectively seal windows against water ingress and wind noise.

Types of Seals

Car window rubber seal factories produce various types of seals, each designed for specific applications within a vehicle. These seals include windshield seals, door window seals, quarter window seals, and rear window seals. Each type has its unique design and function, but all serve the common goal of providing a barrier against environmental elements and maintaining the vehicle's cabin comfort.

For example, windshield seals are designed to create a watertight seal between the windshield glass and the frame of the vehicle, preventing water leaks during heavy rain or car washes. Similarly, door window seals are critical for minimizing wind noise and ensuring that the windows can operate smoothly without hindrance. With the advancements in automotive technology, many car manufacturers are increasingly focused on reducing noise pollution and enhancing overall vehicle performance, thus placing greater emphasis on the quality of rubber seals.

car window rubber seal factories

Sustainability and Innovation

As the automotive industry embraces sustainability, car window rubber seal factories are also evolving to meet these challenges. Many manufacturers are exploring eco-friendly materials and production processes to reduce environmental impact. For instance, the use of recycled rubber and bio-based materials is gaining traction, which aligns with the broader goals of reducing carbon footprints and enhancing resource efficiency.

In addition to sustainability, innovation is a key focus for these factories. Engineers are continually researching and developing new formulas for rubber compounds that provide better performance, longevity, and resistance to extreme temperatures. This innovation not only benefits the manufacturers but also enhances the overall quality and safety of vehicles, providing consumers with a better driving experience.

The Global Supply Chain

Car window rubber seal factories play a crucial role in the global automotive supply chain. With the increasing globalization of manufacturing, many factories have expanded their reach across borders to meet the demands of automobile manufacturers worldwide. This interconnectedness helps ensure that vehicle producers have access to high-quality sealing solutions, regardless of their location.

Moreover, with advancements in logistics and distribution, these factories can efficiently manage inventory, reduce lead times, and ensure timely delivery of products. This responsiveness is essential in an industry where production schedules are tightly coordinated, and delays can have significant financial implications.

Conclusion

In conclusion, car window rubber seal factories are indispensable in the automotive manufacturing landscape. Their ability to produce high-quality, reliable seals contributes significantly to vehicle performance, safety, and comfort. As the industry moves towards greater sustainability and innovation, these factories will continue to adapt and evolve, ensuring that the automotive sector meets the changing needs of consumers and regulatory standards. Ultimately, the work done in these factories is integral to the driving experience, making them a vital component of the modern automotive industry.