ডিসে. . 04, 2024 16:33 Back to list

custom marine fender seals can be customized

Custom Marine Fender Seals Tailoring Solutions for Enhanced Protection

In the maritime industry, safeguarding vessels against the harsh realities of docking and mooring is paramount. One crucial component that helps protect boats, ships, and marine structures is the marine fender. Marine fender seals play an essential role in these systems by providing a cushioning barrier that absorbs the impact between moving vessels and docks. The importance of quality in marine fender seals cannot be overstated, and customization is often the key to meeting specific requirements.

Understanding Marine Fender Seals

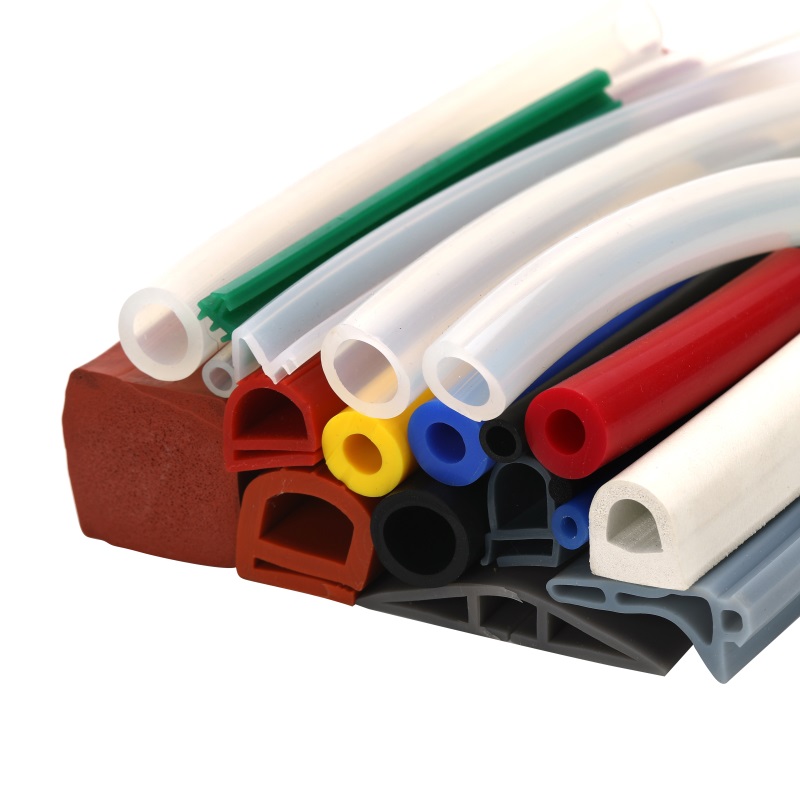

Marine fender seals are typically made from high-quality elastomeric materials that offer durability and resilience. They are designed to reduce shock and stress on vessels during docking maneuvers, which can significantly minimize the risk of structural damage. While standard fender seals are available, they may not meet the unique needs of every application or environment. This is where custom marine fender seals come into play.

The Importance of Customization

The maritime industry is diverse, encompassing everything from small recreational boats to large cargo ships and floating platforms. Each type of vessel has distinct requirements based on its size, weight, and intended use. Custom marine fender seals allow for tailored solutions that address specific challenges. For example, commercial vessels operating in rough seas may require fender seals with enhanced durability and resistance to wear, while yachts often need aesthetically appealing designs that do not compromise performance.

Customization extends beyond just the material; it can also involve the shape and size of the fenders. Traditional cylindrical fenders may not fit all docking scenarios. Custom designs can accommodate unique space configurations, ensuring maximum effectiveness in reducing impacts. By opting for custom fender seals, marine operators can achieve optimal safety and performance tailored precisely to their operational environment.

Material Selection

Choosing the right material for custom marine fender seals is critical. The material must not only withstand various environmental conditions—such as saltwater exposure, UV radiation, and temperature fluctuations—but also provide the necessary cushioning properties to absorb shocks effectively. Common materials used in manufacturing marine fender seals include polyurethane, rubber, and PVC. Each of these materials has specific qualities

custom marine fender seals can be customized

- Polyurethane Known for its superior abrasion resistance and elasticity, polyurethane is ideal for high-performance marine fender seals that undergo substantial stress

.- Rubber Often used for its excellent deformation characteristics, rubber provides a good balance of flexibility and strength, making it suitable for a range of marine applications.

- PVC While it’s less robust than rubber or polyurethane, PVC can be a cost-effective option for lighter-duty applications where extreme impact resistance is not as critical.

Businesses can work closely with manufacturers to choose the best material for their needs, ensuring that the final product meets safety and operational standards.

Tailored Design Process

The process of creating custom marine fender seals typically involves several stages, including consultation, design development, prototyping, and testing. During the consultation phase, engineers assess the specific needs of the vessel, including its size, operational environment, and expected usage patterns. With this information, engineers can create design specifications that optimize performance.

Prototyping is an essential part of this process. It allows for real-world testing of the fender seals before full-scale production. Feedback during this stage is critical, as it provides insights into how the seals perform under actual docking conditions. Any necessary adjustments can be made to ensure that the final product meets all expectations.

Conclusion

In a rapidly evolving maritime industry, where safety and efficiency are non-negotiable, the importance of high-quality marine fender seals cannot be overstated. Customization offers a valuable solution that caters to specific requirements, enhancing the protective capabilities of fender systems. By opting for custom marine fender seals, vessel operators can ensure that they are equipped to handle the rigors of their environments, safeguarding their investments while maintaining high operational efficiency. With advancements in material technology and manufacturing processes, the future looks promising for customized marine fender solutions, paving the way for safer and more effective maritime operations.

Next:

Prev: