নভে. . 04, 2024 17:08 Back to list

EPDM Gaskets for Oil Tank Applications to Ensure Leak Prevention and Durability

The Importance of EPDM Oil Tank Gaskets

In the world of industrial applications, the integrity of storage tanks is paramount, especially when dealing with volatile substances like oils and fuels. One critical component that ensures the reliable sealing of these tanks is the gasket, and when it comes to oil tank gaskets, Ethylene Propylene Diene Monomer (EPDM) has emerged as a leading choice. This article explores the properties, benefits, and applications of EPDM oil tank gaskets.

What is EPDM?

EPDM is a synthetic rubber known for its excellent resistance to heat, ozone, and weathering. This thermoset elastomer is composed of ethylene, propylene, and a diene monomer, which imparts various advantageous properties that make it suitable for demanding environments. Its robust structure not only contributes to its durability but also ensures flexibility, making it an ideal material for gaskets.

Key Properties of EPDM

1. Chemical Resistance One of the standout features of EPDM rubber is its resistance to various chemicals, making it particularly suitable for applications involving oils and fuels. This property minimizes the risk of degradation and ensures long-term performance.

2. Temperature Tolerance EPDM gaskets can withstand a wide range of temperatures, from -40°F to 300°F (-40°C to 150°C). This characteristic is crucial for oil tanks, which can experience fluctuations in temperature due to environmental conditions or changes in product states.

3. Ozone and UV Resistance EPDM is highly resistant to ozone and UV light, which can cause premature aging and cracking in other rubber materials. This feature is essential for outdoor installations where the gaskets may be exposed to harsh weather conditions.

4. Low Compressibility EPDM gaskets maintain their shape under compression, preventing failure due to material deformation. This property ensures a consistent seal, reducing the chances of leaks.

5. Good Elastic Properties The elasticity of EPDM allows it to expand and contract without losing its sealing capabilities, providing reliable performance across varied conditions.

Benefits of Using EPDM Oil Tank Gaskets

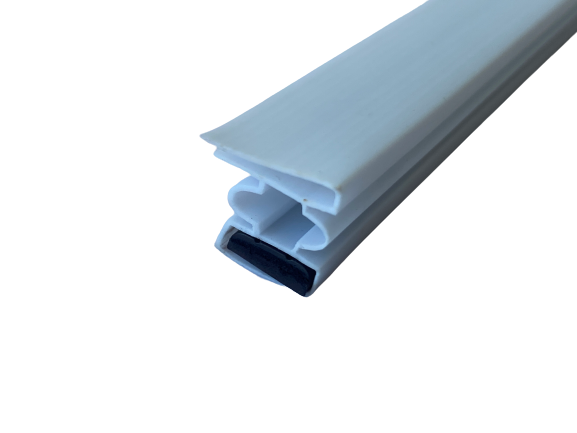

epdm oil tank gasket product

The use of EPDM gaskets in oil tanks offers numerous benefits

- Leak Prevention A well-designed EPDM gasket creates a tight seal, preventing leaks that could lead to environmental contamination and financial loss. - Longevity Due to their resistance to wear and tear, EPDM gaskets have a longer lifespan compared to other materials, reducing the need for frequent replacements and maintenance costs.

- Safety By minimizing leaks and maintaining a secure seal, EPDM gaskets contribute to overall safety in operations, protecting both personnel and the environment.

- Versatility EPDM can be formulated to meet specific operational needs, making it highly customizable for different applications and tank designs.

Applications of EPDM Oil Tank Gaskets

EPDM oil tank gaskets find application across various industries. They are predominantly used in

- Petrochemical Storage For bulk storage of fuels and oils, where sealing properties are crucial to prevent leaks. - Fuel Stations In gas pumps and tanks ensuring that fuel remains secure and uncontaminated.

- Industrial Oil Tanks Used in factories and production facilities where large volumes of oil are stored for machinery and equipment.

- Marine Applications In vessels and offshore rigs where oil is stored and transported under challenging conditions.

Conclusion

In conclusion, EPDM oil tank gaskets are vital components in ensuring the safety, efficiency, and reliability of fuel storage systems. Their unique properties provide excellent resistance to various environmental and chemical factors, making them an outstanding choice for industrial applications. As industries continue to evolve, the demand for high-performance sealing solutions like EPDM gaskets will undoubtedly grow, solidifying their position as a cornerstone in fuel management and storage technology. For operators in this sector, investing in quality EPDM gaskets represents a proactive approach to maintaining operational integrity and environmental stewardship.