অক্টো. . 15, 2024 03:19 Back to list

Optimizing Sealing Solutions for Refrigerated Truck Doors to Enhance Temperature Control

The Importance of Refrigerated Truck Door Seals

In the world of transportation, particularly when it comes to refrigerated trucks, maintaining the integrity of the cold chain is crucial. One often-overlooked element that plays a significant role in this process is the door seal of these trucks. Refrigerated trucks are designed to transport perishable goods, and the effectiveness of these vehicles largely depends on the quality of their door seals.

The primary function of refrigerated truck door seals is to create a barrier that prevents cold air from escaping the cargo area. This is vital for maintaining the proper temperature for sensitive items such as pharmaceuticals, dairy products, meats, and other perishables. The importance of consistent temperatures cannot be overstated; any fluctuations can lead to spoilage, compromising the safety and quality of the products being transported.

Over time, door seals can wear out due to constant opening and closing, exposure to harsh weather conditions, and the friction from loading and unloading goods. Therefore, regular inspection and maintenance of these seals are essential. A damaged or ineffective seal can lead to significant temperature loss, which not only risks the quality of the products but can also result in financial losses for businesses due to rejected shipments and wasted goods.

In addition to preventing temperature fluctuations, door seals contribute to the overall efficiency of the refrigerated truck. A well-sealed door means that the refrigeration unit doesn’t have to work as hard to maintain the desired temperature. This efficiency leads to lower fuel consumption, extending the lifespan of the refrigeration unit, and ultimately saving the company money.

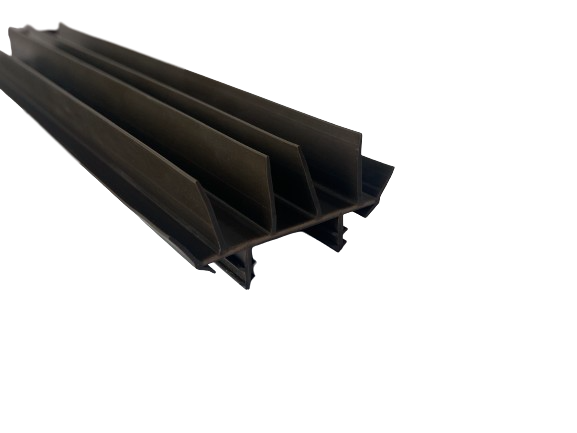

refrigerated truck door seals

There are various materials used for making refrigerated truck door seals, including rubber, silicone, and foam. Each material has its pros and cons in terms of durability, insulation properties, and cost. Rubber seals are commonly used due to their resilience and ability to retain flexibility even in cold temperatures, while silicone seals offer superior heat resistance and can last longer with less wear and tear. It is important for fleet managers to evaluate their specific needs and choose the right material for their refrigerated vehicles.

Additionally, advancements in technology have led to the development of specialized door seals that can further enhance the performance of refrigerated trucks. These modern seals are designed to improve airtightness, ensuring that cold air is retained and the internal environment remains stable. Some seals even come equipped with features that allow for easy installation and replacement, reducing downtime during maintenance.

Beyond the technical aspects, the impact of effective door seals reaches into the broader consumer market. Retailers and consumers are increasingly conscious of food safety and quality. As such, businesses that demonstrate their commitment to maintaining the cold chain through proper refrigerated shipping practices—including the use of high-quality door seals—can build trust and enhance their reputation in the marketplace.

In conclusion, refrigerated truck door seals play a vital role in the transportation of perishable goods. Their primary function is to maintain the internal temperature of the cargo area, ensuring that products arrive in optimal condition. Regular maintenance, material selection, and technological advancements contribute to the effectiveness of door seals, ultimately impacting operational efficiency and customer satisfaction. By prioritizing the integrity of door seals, businesses can safeguard their products, enhance their supply chain reliability, and sustain their reputation in the competitive market for perishable goods. Investing in high-quality door seals isn’t merely a maintenance issue; it’s a strategic move that can lead to long-term success in the logistics and transportation industry.