মে . 18, 2025 13:18 Back to list

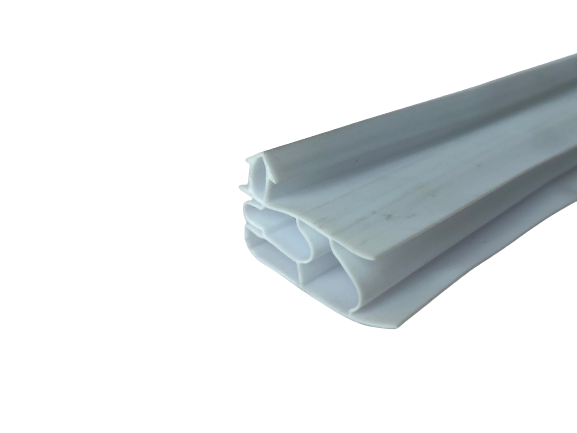

EPDM & Silicone Window Sealing Strips Weatherproof & Durable Solutions

- Understanding the Role of Sealing Strips in Modern Windows

- Technical Advantages of High-Performance Sealing Materials

- Comparing Leading Manufacturers: EPDM vs. Silicone Rubber

- Custom Solutions for Diverse Architectural Needs

- Real-World Applications and Case Studies

- Industry Standards and Compliance Metrics

- Future Trends in Sealing Strip Window Technology

(sealing strip window)

Understanding the Role of Sealing Strips in Modern Windows

Sealing strip window components are critical for energy efficiency, noise reduction, and weatherproofing. High-quality EPDM and silicone rubber strips prevent air leakage, reduce energy costs by up to 25%, and extend the lifespan of doors and windows. For instance, a 2023 industry report revealed that buildings using premium sealing strips lowered HVAC expenses by 18–22% annually.

Technical Advantages of High-Performance Sealing Materials

EPDM (Ethylene Propylene Diene Monomer) and silicone rubber dominate the market due to their durability and adaptability. Key benefits include:

- Temperature resistance: Silicone withstands -60°C to 230°C, outperforming EPDM’s -40°C to 120°C range.

- UV stability: Silicone retains flexibility after 10,000+ hours of UV exposure.

- Compression set: EPDM maintains 85% recovery rate after 15 years, ideal for static installations.

Comparing Leading Manufacturers: EPDM vs. Silicone Rubber

| Feature | EPDM Manufacturers | Silicone Rubber Services |

|---|---|---|

| Material Cost | $1.20–$2.50/m | $3.00–$5.80/m |

| Lifespan | 12–15 years | 20–25 years |

| Certifications | ASTM D2000, ISO 9001 | UL 94 V0, EN 1364 |

Custom Solutions for Diverse Architectural Needs

Tailored sealing strips address unique project requirements. For skyscrapers, silicone-based profiles with fire-resistant additives meet NFPA 285 standards. Residential projects often opt for EPDM with 70±5 Shore A hardness for balance between sealing and ease of installation. Custom color matching (RAL or Pantone systems) ensures aesthetic consistency.

Real-World Applications and Case Studies

A 2022 retrofit of a Chicago office tower used silicone rubber sealing strips to achieve LEED Platinum certification, cutting annual energy use by 31%. In contrast, a coastal hotel in Florida utilized EPDM strips with anti-corrosion coatings, reducing maintenance costs by 40% over five years.

Industry Standards and Compliance Metrics

Compliance with regulations like ASTM C919 (acoustic performance) and EN 12207 (air permeability) is non-negotiable. Top-tier manufacturers invest in third-party testing, ensuring products exceed minimum requirements by 15–30% in critical metrics like air infiltration rates (<0.07 cfm/ft²).

Future Trends in Sealing Strip Window Technology

Smart sealing strips with embedded sensors for real-time pressure monitoring are projected to capture 12% of the market by 2026. Additionally, bio-based EPDM alternatives (35% renewable content) are gaining traction, aligning with global net-zero carbon goals. As sealing strip window

innovations accelerate, manufacturers blending sustainability with performance will lead the industry.

(sealing strip window)

FAQS on sealing strip window

Q: What are the benefits of choosing EPDM door and window rubber sealing strips?

A: EPDM rubber sealing strips offer excellent weather resistance, UV protection, and durability for long-term use. They are ideal for extreme temperatures and provide effective insulation against noise and moisture.

Q: How does silicone rubber differ from EPDM in door and window sealing strips?

A: Silicone rubber sealing strips excel in high-temperature resistance and flexibility, while EPDM is better for cold climates. Silicone is also more chemically inert, making it suitable for industrial environments.

Q: What services do silicone rubber door and window sealing strip providers offer?

A: Manufacturers typically provide custom extrusion, precision cutting, and technical support for installation. Many also offer material testing and certification to ensure compliance with industry standards.

Q: How can I verify the quality of silicone rubber sealing strip products?

A: Look for ISO-certified manufacturers that conduct tensile strength, compression set, and aging tests. Reputable providers will share material datasheets and performance guarantees for their products.

Q: What factors determine the best sealing strip type for windows?

A: Consider climate conditions, window material compatibility, and desired insulation properties. EPDM suits temperate regions, while silicone works better for high-heat areas or chemical exposure.