ডিসে. . 05, 2024 15:47 Back to list

Ship Anti-Collision Rubber Sealing Strip Cost Estimates and Supplier Information

The Importance of Ship Anti-Collision Rubber Sealing Strips A Comprehensive Overview

In the maritime industry, safety is paramount. One critical aspect of ensuring safety on ships is the incorporation of anti-collision mechanisms, particularly rubber sealing strips. These innovative components are designed to provide both protection and longevity to the vessels, and their relevance cannot be overstated.

Understanding Anti-Collision Rubber Sealing Strips

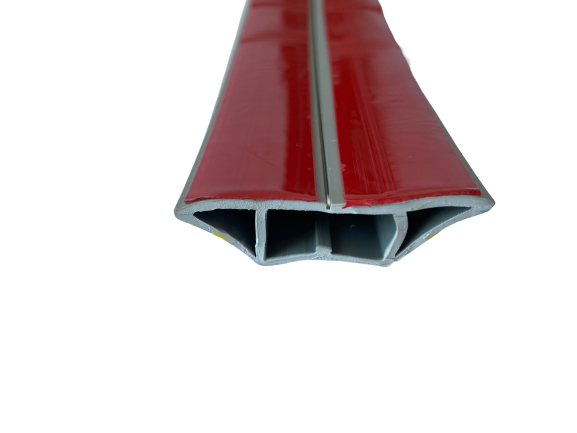

Anti-collision rubber sealing strips are engineered to bear the brunt of impacts that can occur during docking, berthing, or collisions with other vessels or obstacles in the water. These strips are usually made from high-quality rubber compounds that possess exceptional elasticity and resilience. They effectively absorb shock, reducing the risk of damage to the ship's hull and ensuring the safety of crew and cargo.

The primary function of these sealing strips is to create a cushioning barrier that minimizes the effects of impact. When a ship collides with the dock or another vessel, the rubber strips compress and then rebound. This unique property allows them to dissipate the energy released during a collision, safeguarding the structure of the ship and its contents.

Key Benefits of Using Anti-Collision Rubber Sealing Strips

1. Enhanced Protection By acting as a buffer between the ship and potential hazards, anti-collision rubber sealing strips significantly reduce the risk of hull damage. This protection not only extends the life of the vessel but also minimizes repair costs, making them a wise investment.

2. Improved Safety The presence of these sealing strips contributes to the overall safety of operations in ports and harbors. They provide an additional layer of security, helping to prevent accidents that may arise from collisions.

3. Cost Efficiency While the initial investment in high-quality rubber sealing strips may seem substantial, the long-term savings due to reduced maintenance and repair costs make them an economically viable choice. They help avoid downtime that could be detrimental to shipping schedules.

ship anti-collision rubber sealing strip quotes

4. Versatility Anti-collision rubber sealing strips can be tailored to fit various types of vessels, including ferries, cargo ships, and yachts. Their adaptability means they can be used across a wide range of marine applications, ensuring comprehensive protection.

5. Environmental Resistance These rubber strips are specifically formulated to withstand harsh marine environments. They are resistant to saltwater, UV radiation, and temperature variations, ensuring their durability despite exposure to the elements.

Selecting the Right Anti-Collision Rubber Sealing Strips

When choosing anti-collision rubber sealing strips, several factors must be considered to ensure optimal performance

- Material Quality The type of rubber used in the manufacturing of sealing strips significantly impacts their effectiveness. High-grade materials provide better shock absorption and longevity.

- Design and Size The design and dimensions of the strips should be suitable for the vessel’s specific needs. Consulting with marine engineers can help ensure a perfect fit.

- Manufacturer Reputation Always choose sealing strips from reputable manufacturers who guarantee quality and compliance with maritime safety standards.

Conclusion

In summary, the importance of ship anti-collision rubber sealing strips cannot be overlooked in the maritime industry. They serve as a critical component in safeguarding vessels against impacts, contributing to the overall safety and efficiency of marine operations. As shipping continues to grow, investing in quality anti-collision measures like rubber sealing strips will undoubtedly pay dividends in terms of protection, cost savings, and peace of mind. In an era where safety and cost efficiency are paramount, incorporating these critical components is not just an option; it is a necessity.