ডিসে. . 13, 2024 05:51 Back to list

solid neoprene rubber strips

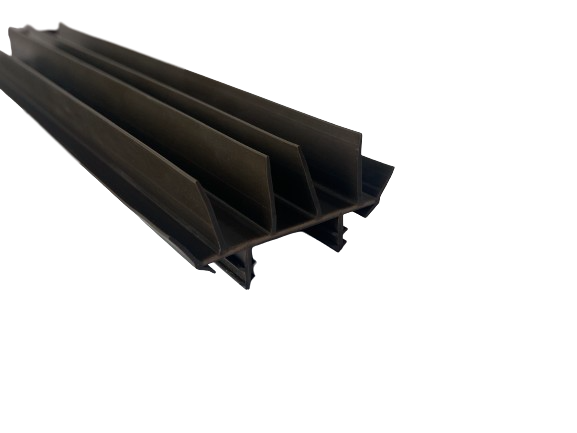

Solid Neoprene Rubber Strips Versatile Solutions for Various Applications

Neoprene, a synthetic rubber, is renowned for its remarkable durability, flexibility, and resistance to various environmental conditions. Among the various forms in which neoprene is available, solid neoprene rubber strips stand out due to their adaptability and wide range of uses across different industries. These strips offer unique properties that make them an essential choice for applications ranging from industrial manufacturing to home DIY projects.

What is Solid Neoprene?

Solid neoprene rubber is a closed-cell material that possesses excellent insulation and cushioning characteristics. Its composition gives it a unique ability to resist aging, ozone, and UV radiation, making it suitable for outdoor applications as well as indoor uses. Additionally, solid neoprene is resistant to common chemicals, oils, and fuels, which further enhances its functional capabilities in various settings.

Key Features and Benefits

1. Durability One of the most significant advantages of solid neoprene rubber strips is their high durability. They are designed to withstand mechanical stress, making them ideal for heavy-duty applications. Whether used in manufacturing or as a cushioning material, these strips retain their integrity over time.

2. Water Resistance Solid neoprene is inherently water-resistant, which makes it an excellent choice for applications that require moisture protection. This characteristic is particularly beneficial in marine environments or where exposure to water is frequent.

3. Temperature Stability These strips can perform well in a wide range of temperatures, from subzero conditions to high heat. This thermal stability makes solid neoprene rubber strips suitable for various industries, including automotive, construction, and aerospace.

solid neoprene rubber strips

4. Customization Solid neoprene rubber strips are highly customizable. They can be manufactured in various widths, lengths, and thicknesses to meet specific project requirements. This adaptability ensures that users can find the perfect fit for their unique applications.

Common Applications

1. Industrial Uses In manufacturing environments, solid neoprene rubber strips are often used as seals, gaskets, and spacers. Their ability to provide excellent cushioning and insulation makes them ideal for machinery and equipment, helping to minimize vibration and noise.

2. Marine Applications The marine industry benefits from solid neoprene rubber strips due to their water and UV resistance. They are commonly used in boat seals, fendering systems, and flooring mats, providing safety and protection against the elements.

3. Automotive Industry Solid neoprene strips are widely used in vehicles for weather stripping and insulation. They help maintain cabin temperature while reducing noise and vibration, enhancing the overall driving experience.

4. Soundproofing Due to their density and vibration-damping properties, solid neoprene rubber strips are also effective for soundproofing applications. They can be used in walls, ceilings, and floors to reduce noise transmission in residential and commercial buildings.

Conclusion

Solid neoprene rubber strips represent an invaluable resource across a multitude of industries. Their blend of durability, weather resistance, and customization options makes them a favored choice for engineers, builders, and hobbyists alike. As technology continues to advance and the demands for high-performance materials increase, solid neoprene rubber strips will undoubtedly remain a critical component in delivering solutions that meet both functional and aesthetic needs. Whether you are working on an industrial project or a home improvement task, these versatile strips can provide reliable performance and peace of mind.