okt . 19, 2024 04:56 Back to list

Customizable High-Quality Marine Fender Rubber Sealing Strip Solutions for Your Needs

High-Quality Customizable Marine Fender Rubber Sealing Strips

In the maritime industry, ensuring the safety and protection of vessels during docking and mooring is of utmost importance. One of the key components that play a crucial role in this process is marine fenders. These protective devices help absorb the kinetic energy of a ship during berthing, preventing damage to both the vessel and the dock. However, the effectiveness of marine fenders can be significantly enhanced through the use of high-quality customizable rubber sealing strips.

Understanding Marine Fender Rubber Sealing Strips

Marine fender rubber sealing strips are specially designed components that serve multiple purposes. They not only enhance the performance of marine fenders by providing an additional layer of protection but also contribute to the longevity of the fender itself. Made from robust and durable rubber materials, these strips are crafted to withstand harsh marine environments, including exposure to saltwater, UV rays, and extreme weather conditions.

The customization aspect of these sealing strips allows for a tailored fit to various fenders and berthing structures. Whether it’s a large commercial vessel or a smaller recreational boat, having the right sealing strip can make a significant difference in how well the fender functions. Customizable options can include different sizes, shapes, and rubber compounds to suit specific operational needs.

Benefits of High-Quality Customizable Sealing Strips

1. Enhanced Protection High-quality rubber sealing strips provide a barrier that absorbs impact energy, reducing the risk of damage to both the vessel and the dock. This protective layer ensures that vessels can dock safely, even in adverse weather conditions or strong currents.

2. Increased Durability The durability of marine fender rubber sealing strips is crucial for their long-term performance. Quality materials and manufacturing processes ensure that the strips resist wear and tear, extending the lifecycle of both the seal and the fender.

high quality customizable marine fender rubber sealing strip

3. Cost-Effectiveness By investing in customized rubber sealing strips, businesses can save money in the long run. Reducing damage to vessels and docks translates to fewer repairs and maintenance costs. Additionally, the longer lifespan of high-quality sealing strips means less frequent replacements.

4. Improved Performance Customizable sealing strips enhance the overall performance of marine fenders. When seals fit perfectly, they can provide optimal cushioning and support during the berthing process, which is especially important in busy ports where numerous vessels might be docking simultaneously.

5. Versatile Applications These sealing strips are applicable across a wide range of maritime sectors, from commercial shipping and fishing industries to recreational boating. Their versatility makes them an essential component in various marine operations.

Common Materials and Customization Options

Marine fender rubber sealing strips are typically made from several types of rubber, including EPDM, neoprene, and natural rubber. Each material offers distinct advantages, such as resistance to weathering, flexibility, and oil resistance, allowing for a choice that best meets the specific environmental demands of a project.

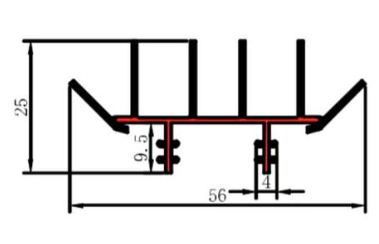

Customization can incorporate factors such as the thickness of the strip, the profile shape (like flat, round, or concave), and even bespoke lengths to accommodate unique fender shapes. These options ensure that users can find a solution that perfectly aligns with their operational requirements.

Conclusion

In conclusion, high-quality customizable marine fender rubber sealing strips are crucial for maintaining the safety and efficiency of maritime operations. With their ability to provide enhanced protection, increased durability, and cost-effectiveness, these strips are indispensable in the industry. By choosing the right materials and customization options, vessel operators can significantly improve their docking processes and ensure the longevity of their marine fenders, ultimately contributing to safer waterways and better marine practices.