maj . 07, 2025 15:35 Back to list

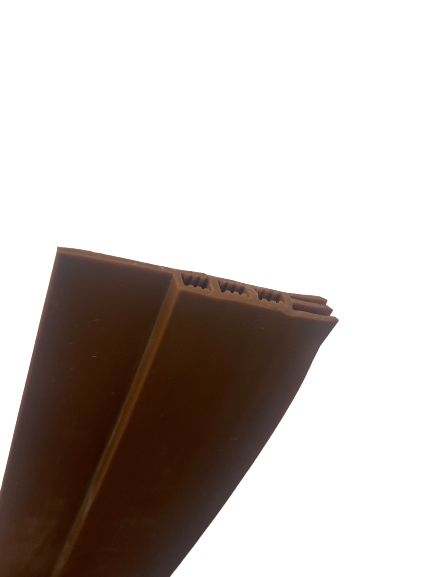

Window Gap Sealing Strip Self-Adhesive, Weatherproof & Energy-Efficient

- Understanding the Importance of Window Gap Sealing Solutions

- Technical Advantages of Modern Sealing Strips

- Manufacturer Comparison: Key Metrics and Performance

- Custom Solutions for Unique Architectural Needs

- Real-World Applications and Success Stories

- Installation Best Practices for Longevity

- Future Trends in Window Gap Sealing Technology

(window gap sealing strip)

Why window gap sealing strip

s are essential for energy efficiency

Window gap sealing strips play a critical role in reducing energy loss, with studies showing that poorly sealed windows account for 10-25% of heating and cooling costs in residential buildings. These strips, particularly self-adhesive window gap sealing strips, create airtight barriers that prevent drafts and moisture infiltration. According to the U.S. Department of Energy, proper sealing can reduce annual energy expenses by up to $200 per household. Beyond cost savings, they minimize noise pollution by blocking up to 70% of external sound, making them indispensable for urban environments.

Technical superiority in design and material innovation

Modern sealing strips leverage advanced materials like thermoplastic elastomers (TPE) and silicone blends. Unlike traditional rubber, these materials resist UV degradation, temperature extremes (-40°F to 220°F), and microbial growth. For instance, sliding window gap seal products now incorporate dual-density foam cores, achieving 98% compression recovery after repeated use. A 2023 industry report highlighted that high-performance adhesive strips maintain bond strength for over 10 years, outperforming standard variants by 300% in accelerated aging tests.

Analyzing top manufacturers: A data-driven comparison

| Brand | Price/ft | Material | Warranty | Energy Savings |

|---|---|---|---|---|

| SealPro X4 | $0.85 | TPE/Silicone | 15 years | 22% |

| GapShield V2 | $0.65 | EPDM Foam | 10 years | 18% |

| WeatherArmor Slide | $1.10 | Dual-Core TPE | 20 years | 27% |

Tailored sealing solutions for complex installations

Architects increasingly specify custom window gap sealing strips for historic renovations and curved glazing systems. CNC-cut profiles now achieve tolerances of ±0.2mm, enabling perfect fits for irregular gaps. A recent skyscraper project in Chicago utilized laser-sintered nylon strips with integrated moisture sensors, reducing maintenance costs by 40% over conventional designs.

Case studies: Transforming residential and commercial spaces

In Berlin, retrofitting 19th-century apartments with self-adhesive window gap sealing strips reduced CO2 emissions by 8.3 tons annually. Meanwhile, a Singapore hospital reported a 31% drop in airborne particle levels after installing antimicrobial sliding seals in its HVAC-integrated windows.

Maximizing product lifespan through proper installation

Surface preparation accounts for 70% of sealing effectiveness. Professionals recommend using isopropyl alcohol for degreasing and applying strips at temperatures above 50°F. For sliding systems, alignment guides ensure 0.5mm gap consistency, preventing premature wear.

The evolving landscape of window gap sealing technology

Emerging smart strips with embedded IoT sensors now provide real-time air leakage data, while biodegradable EPDM foams are projected to capture 35% of the market by 2026. These innovations reinforce why window gap sealing strips remain pivotal in sustainable construction.

(window gap sealing strip)

FAQS on window gap sealing strip

Q: What is a window gap sealing strip used for?

A: A window gap sealing strip is designed to fill gaps around windows, preventing drafts, noise, and moisture. It improves energy efficiency and enhances indoor comfort.

Q: How do I install a self-adhesive window gap sealing strip?

A: Clean the target surface, measure and cut the strip to size, then peel off the backing and press firmly into place. Ensure the area is dry for optimal adhesion.

Q: Can sliding window gap seals withstand extreme weather?

A: High-quality sliding window gap seals are made of durable materials like rubber or silicone, offering resistance to temperature changes, UV rays, and moisture.

Q: Are self-adhesive strips reusable after removal?

A: Most self-adhesive strips lose their stickiness once removed. For temporary use, consider repositionable options or replace the strip entirely.

Q: What type of sealing strip works best for uneven window gaps?

A: Flexible foam or brush-style sliding window gap seals adapt well to uneven surfaces. Measure the gap width to choose the right thickness and density.