Feb. . 20, 2025 12:00 Back to list

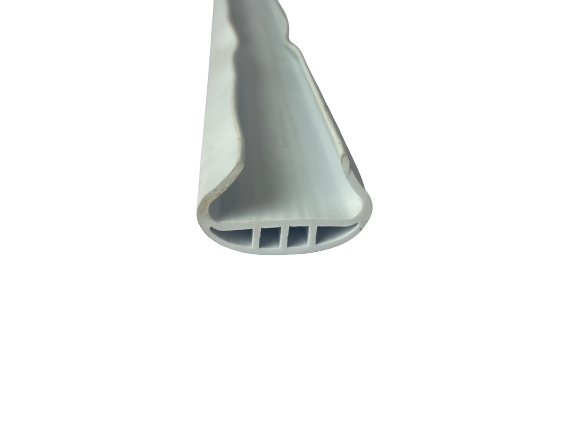

L-shaped staircase anti-skid strip

When examining solutions for enhancing energy efficiency and soundproofing in both residential and commercial buildings, the purchase of EPDM (Ethylene Propylene Diene Monomer) composite sponge door sealing strips emerges as a top choice for many industry experts. Not only are these sealing strips pivotal in minimizing energy costs by preventing unwanted air exchange, but they also offer remarkable durability and performance, making them an invaluable asset for any building project.

To build trustworthiness in their use, it is crucial to underscore the ease of installation and maintenance associated with these sealing strips. For both DIY enthusiasts and professional installers, the process of fitting EPDM strips is straightforward, requiring minimal tools and skills. Once installed, they demand little to no maintenance, demonstrating long-term value as they continue to function efficiently without frequent replacements. Such attributes not only save time and resources but also contribute to sustainability efforts by reducing waste and enhancing building longevity. The growing trend toward green building practices further highlights the importance of EPDM composite sponge door sealing strips. By effectively sealing gaps around doors, they play a vital role in improving a building's energy efficiency, a key consideration for LEED certification and other environmental standards. By choosing EPDM, building owners and developers not only adhere to regulations but also demonstrate a commitment to sustainable construction, appealing to eco-conscious consumers and tenants. In summary, EPDM composite sponge door sealing strips are an exemplary product marked by durability, effectiveness, and environmental responsibility. Their performance in various conditions, combined with easy installation and minimal upkeep, makes them a preferred choice across the construction industry. As buildings continue to adapt to the evolving demands for efficiency and sustainability, investing in EPDM sealing technology stands as a smart, future-ready decision that aligns with both economic and environmental goals.

To build trustworthiness in their use, it is crucial to underscore the ease of installation and maintenance associated with these sealing strips. For both DIY enthusiasts and professional installers, the process of fitting EPDM strips is straightforward, requiring minimal tools and skills. Once installed, they demand little to no maintenance, demonstrating long-term value as they continue to function efficiently without frequent replacements. Such attributes not only save time and resources but also contribute to sustainability efforts by reducing waste and enhancing building longevity. The growing trend toward green building practices further highlights the importance of EPDM composite sponge door sealing strips. By effectively sealing gaps around doors, they play a vital role in improving a building's energy efficiency, a key consideration for LEED certification and other environmental standards. By choosing EPDM, building owners and developers not only adhere to regulations but also demonstrate a commitment to sustainable construction, appealing to eco-conscious consumers and tenants. In summary, EPDM composite sponge door sealing strips are an exemplary product marked by durability, effectiveness, and environmental responsibility. Their performance in various conditions, combined with easy installation and minimal upkeep, makes them a preferred choice across the construction industry. As buildings continue to adapt to the evolving demands for efficiency and sustainability, investing in EPDM sealing technology stands as a smart, future-ready decision that aligns with both economic and environmental goals.