Okt. . 22, 2024 15:10 Back to list

container door rubber seal

The Importance of Container Door Rubber Seals Ensuring Security and Efficiency

In the logistics and shipping industry, the integrity of a container's contents is paramount. One of the most critical yet often overlooked components that contribute to this integrity is the rubber seal used on container doors. These seals play a vital role in ensuring that cargo remains secure, safe, and unaffected by external elements during transit.

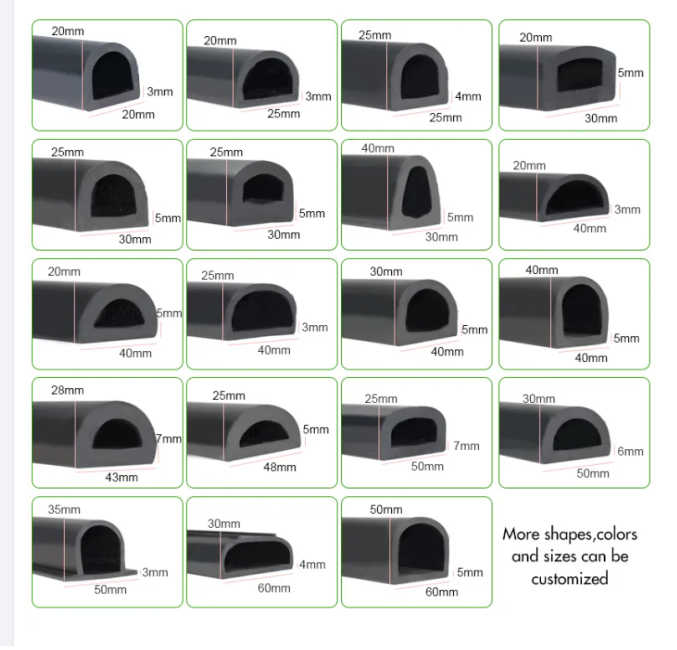

Rubber seals are designed to provide a tight and effective barrier between the inside of the container and the outside environment. They are typically made from high-quality rubber compounds that are resistant to wear and tear, UV rays, and extreme weather conditions. This durability ensures that the seals maintain their integrity over numerous voyages, protecting the contents of the container from rain, dust, and other environmental factors that could compromise the goods inside.

One of the primary functions of container door rubber seals is to provide a watertight and airtight seal that prevents moisture and air from entering the container

. This is particularly important for sensitive cargo such as food products, electronics, and pharmaceuticals, which can be adversely affected by even small amounts of moisture or exposure to air. The presence of a functional rubber seal reduces the risk of mold, corrosion, and spoilage, thereby maintaining the quality and value of the products being transported.container door rubber seal

In addition to their protective capabilities, rubber seals also aid in securing the container. A properly fitting seal ensures that the doors are securely closed, deterring theft and tampering during transit. This added layer of security is essential for businesses that rely on the safe transportation of high-value merchandise. The presence of undamaged rubber seals can also serve as an indicator of the container's condition, helping logistics personnel assess whether the container has been compromised in any way during transport.

Over time, however, rubber seals can experience wear and degradation due to exposure to harsh conditions. Factors such as extreme temperatures, prolonged UV exposure, and physical abrasion can cause the rubber to crack or lose its elasticity. Therefore, regular inspection and maintenance of container door seals are critical to ensure their continued effectiveness. Logistics companies should provide training for their staff to identify signs of wear and to replace seals promptly to avoid potential issues.

Investing in high-quality rubber seals for container doors is not just a matter of compliance; it is a commitment to maintaining the highest standards of cargo safety and quality. As businesses increasingly operate on a global scale, the importance of reliable shipping solutions cannot be overstated. By ensuring that container door seals are functioning optimally, companies can safeguard their products, enhance customer satisfaction, and ultimately improve their bottom line.

In conclusion, container door rubber seals are indispensable components that play a crucial role in the logistics and shipping industries. Their ability to provide a secure and protective barrier for cargo directly impacts the efficiency and reliability of global trade. By prioritizing the quality and maintenance of these seals, companies can ensure that their shipments reach their destinations in optimal condition, allowing them to thrive in a competitive marketplace.