Nov. . 10, 2024 02:09 Back to list

Custom Silicone Rubber Seals for Oven Doors from Leading Exporters and Suppliers

Customizable Silicone Rubber Seals for Oven Doors A Comprehensive Overview for Exporters

In the competitive world of kitchen appliances, the importance of quality components cannot be overstressed. One such critical component is the silicone rubber seal for oven doors. As manufacturers and exporters delve into the global market, the demand for customizable silicone rubber seals has surged, making it imperative to understand the key aspects of this product.

Silicone rubber seals have gained popularity due to their excellent thermal resistance, durability, and flexibility. They not only provide a reliable barrier against heat escape but also comply with food safety standards, making them ideal for cooking appliances. Since ovens are subjected to extreme temperatures, the choice of material is crucial. Silicone rubber can withstand temperatures ranging from -60°C to 230°C (-76°F to 446°F), ensuring low thermal conductivity and preventing energy loss. This characteristic is particularly beneficial for energy-efficient ovens, aligning with sustainability trends.

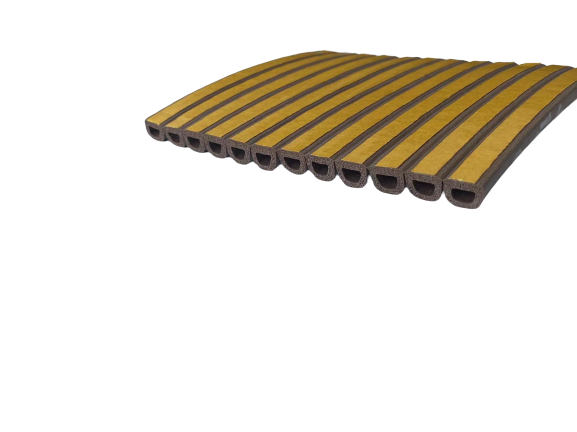

One of the primary advantages of silicone rubber seals is their versatility. Exporters can customize these seals to meet diverse specifications. Whether it’s the size, color, thickness, or hardness, manufacturers can tailor products according to the unique requirements of their clients. This adaptability is particularly vital in today’s market, where bespoke solutions are preferred. For exporters, offering customizable options can help them cater to a broader clientele while enhancing their competitive edge.

Moreover, the production process of silicone rubber seals contributes to their strong marketability. These seals are generally made using a combination of silicone and other additives, allowing for improved performance characteristics such as enhanced UV stability, weather resistance, and longevity. Advanced manufacturing technologies like injection molding or extrusion can produce seals that conform perfectly to the contours of various oven doors. This precision ensures a tight fit and effective sealing, which, in turn, helps businesses reduce recall risks associated with subpar components.

customizable silicone rubber seal for oven door exporters

When exporting silicone rubber seals for oven doors, it is vital to consider regulatory compliance. Different countries have varying regulations regarding kitchen appliances and their components. Exporters must ensure that their products meet applicable safety standards and certifications, such as FDA approval in the United States or EU specifications. Maintaining these standards not only enhances the reputation of exporters but also instills confidence in customers regarding the safety and reliability of the products they are purchasing.

Sustainability is a growing concern across all industries, including kitchen appliances. Silicone rubber is a more environmentally friendly option compared to many traditional materials. Unlike plastics, silicone rubber does not degrade into harmful microplastics, making it a preferred choice for eco-conscious manufacturers. Exporters can capitalize on this trend by highlighting the environmentally friendly aspects of their silicone rubber seals, appealing to a market that increasingly prioritizes sustainability.

Networking and collaboration also play a critical role in expanding an exporter’s reach. By forging partnerships with manufacturers of ovens and kitchen appliances, exporters can create synergies that enhance their market visibility. Participation in trade fairs and industry exhibitions provides opportunities to showcase customizable silicone rubber seals to a global audience, facilitating potential partnerships and sales leads.

In conclusion, the market for customizable silicone rubber seals for oven doors presents significant opportunities for exporters. With their versatility, resilience, and alignment with sustainability trends, these components are essential in the production of high-quality kitchen appliances. By focusing on customization, compliance, and collaboration, exporters can strategically position themselves in the competitive landscape of the kitchen appliance industry, ensuring long-term success and growth. The future is bright for those who embrace innovation and quality in their product offerings.