Dez. . 06, 2024 07:56 Back to list

epdm oil tank gasket company

EPDM Oil Tank Gasket Ensuring Reliability and Performance in Industrial Applications

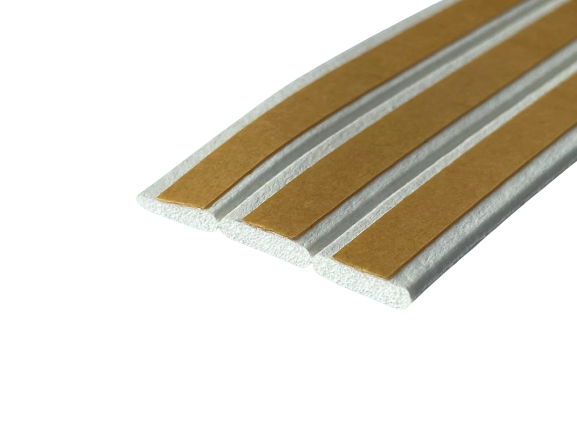

In the dynamic world of industrial operations, the significance of effective sealing solutions cannot be overstated. One of the essential components catering to this need is the EPDM (Ethylene Propylene Diene Monomer) gasket. Used primarily in oil tanks and various other applications, EPDM gaskets offer an ideal fusion of flexibility, durability, and chemical resistance, making them an essential choice for industries handling oils and other hydrocarbons.

What is EPDM?

EPDM is a synthetic rubber that boasts superior weather resistance compared to traditional elastomers. Its molecular structure allows for exceptional performance in extreme temperatures, ranging from as low as -40°C to as high as 120°C. This temperature flexibility is critical for oil tank applications, where fluctuations can be significant. Furthermore, EPDM exhibits excellent resistance to UV radiation, ozone, and aging—traits that make it suitable for outdoor use and environments subjected to harsh conditions.

Applications of EPDM Gaskets in Oil Tanks

Oil tanks are crucial infrastructure in the energy sector, storing vast amounts of crude oil, refined products, and other processed hydrocarbons. The integrity of these tanks directly influences safety, environmental compliance, and operational efficiency. A malfunctioning gasket can lead to leaks, which pose environmental hazards and can incur costly fines from regulatory bodies.

EPDM gaskets are specifically designed for these applications, offering numerous advantages

1. Chemical Resistance EPDM has a high tolerance for various chemicals, including oils, fuels, and lubricants. This makes it particularly effective for oil tank applications where exposure to hydrocarbons is inevitable.

2. Temperature Stability As previously mentioned, EPDM remains stable across a broad temperature range. This characteristic ensures that the gasket maintains its integrity, preventing leaks and failures even in extreme conditions.

3. Durability EPDM gaskets are known for their longevity. Their resistance to wear and deformation enables them to maintain effective sealing performance over extended periods, reducing maintenance costs and downtime.

4. Flexibility and Compression Set Resistance The inherent flexibility of EPDM allows it to compress effectively and create a tight seal, accommodating variations in tank surfaces and contours. Its minimal compression set ensures that the gasket recovers its shape after compression, promoting long-term sealing effectiveness.

epdm oil tank gasket company

5. Ease of Installation EPDM gaskets can be manufactured in various shapes and sizes to fit specific applications. Their lightweight nature aids in easy handling and installation, which is crucial in large industrial setups.

Choosing the Right EPDM Gasket Manufacturer

Selecting a reliable manufacturer for EPDM oil tank gaskets is paramount to ensuring the performance and safety of your operations. Companies specializing in this sector typically undergo stringent quality control measures and adhere to relevant industry standards.

When considering a gasket supplier, organizations should evaluate several factors

- Experience and Expertise A company with a solid track record in manufacturing EPDM gaskets for oil tanks will likely have the technical know-how to meet your specific needs.

- Customization Options Every oil tank has unique requirements, and a good manufacturer should offer customization services to ensure that the gaskets fit perfectly and perform optimally.

- Certifications Look for manufacturers that comply with international standards and possess certifications relevant to oil and gas operations, which can be a testament to their commitment to quality.

- Customer Support Reliable customer service can make a significant difference, particularly when it comes to troubleshooting and the provision of technical support.

Conclusion

EPDM oil tank gaskets play an indispensable role in securing the integrity and safety of oil storage facilities. Their unmatched chemical resistance, temperature stability, and longevity make them one of the best choices for industrial operations dealing with oil. By partnering with a reputable gasket manufacturer, companies can ensure that they receive high-quality products that meet rigorous industry standards, ultimately enhancing operational efficiency and environmental compliance. Selecting the right EPDM gasket is not just a matter of choice; it is a critical step in safeguarding both the environment and industrial assets.