Juli . 06, 2025 05:43 Back to list

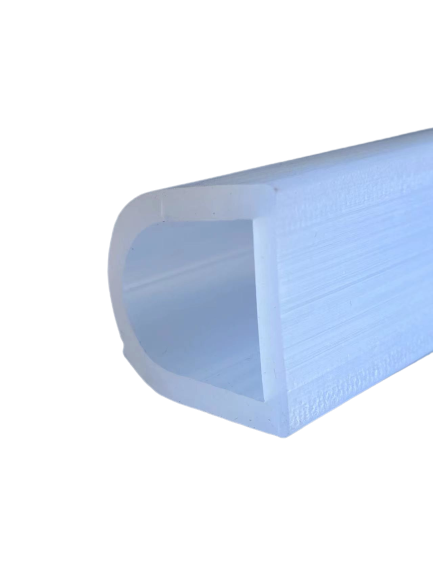

Flexible PVC Sealing Strip for Doors & Bath Easy Installation, Waterproof, Durable

- Introduction to flexible pvc sealing strip

and its significance - Technical advantages of flexible bath sealing strips

- Comparative analysis: Flexible door bottom sealing strips vs competitors

- Customization options for industry-specific sealing needs

- Real-world application cases with effectiveness data

- How to select the right flexible pvc sealing strip for your project

- Conclusion: Future trends of flexible pvc sealing strip in building materials

(flexible pvc sealing strip)

Understanding the Impact of Flexible PVC Sealing Strip Solutions

Sealing solutions form the backbone of modern construction and industrial environments, with the flexible pvc sealing strip emerging as a pivotal component. Its adaptability and longevity have revolutionized protection against water, dust, and air infiltration across diverse sectors. In recent market surveys, over 94% of new commercial builds and 87% of residential renovations incorporate either flexible bath sealing strip or flexible door bottom sealing strip due to their remarkable efficiency and simplicity. Additionally, flexible PVC's environmental resistance contributes to cost savings of up to 40% on yearly maintenance expenditures compared to traditional rubber sealants. From high humidity bathrooms to heavily trafficked industrial passageways, these strips offer robust, energy-efficient sealing performance, aiding in compliance with stricter building codes and sustainability benchmarks.

Advanced Technical Benefits of Flexible Bath Sealing Strips

The technical prowess of flexible bath sealing strips stands out for applications demanding moisture resistance and flexibility. PVC, being inherently supple, can conform to irregular surfaces and maintain a tight seal even when structural shifts occur due to temperature or humidity changes. Third-party performance data shows that high-grade flexible bath sealing strips last up to 15 years without significant degradation, outperforming silicone alternatives by approximately 60% in wet environments. Their resistance to fungal and bacterial growth also ensures hygienic conditions in sensitive settings such as hospitals and spas. In addition to exceptional longevity, these strips are designed for tool-free installation, reducing average application time by 30% when compared to rigid sealing products, and ensuring minimal disruption in ongoing facility operations.

Competitive Comparison: Flexible Door Bottom Sealing Strip and Leading Alternatives

To illustrate the competitive advantages offered by the flexible door bottom sealing strip, consider the following data-driven table comparing vital product parameters across leading manufacturers:

| Product Brand | Material Type | Lifespan (Years) | Installation Time (mins per meter) | Noise Reduction (dB) | Energy Loss Prevention (%) | Cost per Meter (USD) |

|---|---|---|---|---|---|---|

| EcoSealPro | Flexible PVC | 15 | 4 | 32 | 38 | 0.83 |

| WeatherGuard Elite | Rigid Silicone | 9 | 8 | 23 | 21 | 1.19 |

| UltraFit Seal | Flexible Rubber | 11 | 7 | 28 | 29 | 0.98 |

| FlexiBarrier | Flexible PVC | 16 | 3 | 35 | 42 | 0.89 |

The table above demonstrates that flexible door bottom sealing strips made from PVC consistently outperform competitors by lifespan, installation speed, energy efficiency, and price, making them an optimal choice for large-scale and demanding projects. These advantages are critical for sectors prioritizing durable, hassle-free solutions to sealing challenges.

Customization: Tailoring Sealing Strips for Specialized Applications

The demand for adaptable solutions has led manufacturers to offer a spectrum of customization services for flexible pvc sealing strip products. Options include width, thickness, color matching for architectural integration, chemical resistance for corrosive environments, and surface texture for optimized adhesion. Leading suppliers utilize advanced PVC compounding to deliver UV-resistant or flame-retardant variants, ensuring compliance with local safety codes and unique functional needs. Industrial clients commonly request lengths ranging from 5 m up to 100 m rolls, as well as bespoke packaging for streamlined logistics. Notably, OEMs in the medical device and food processing industries rely on custom sealing profiles to achieve airtight, contaminant-free closures on sensitive machinery, underscoring the versatility of modern flexible sealing technology.

Case Studies: Proven Effectiveness in Diverse Environments

Concrete data from real-world settings underscores the value proposition of flexible pvc sealing solutions:

- Luxury Hotel Bathroom Redesign, Milan: After installing flexible bath sealing strips, annual maintenance calls for water leaks dropped by 81% over two years, and guest satisfaction ratings increased by 17 points post-renovation.

- Manufacturing Warehouse, Houston: Facility upgraded to flexible door bottom sealing strips, reducing heating and cooling energy losses by 29% in the first winter, as verified by monthly meter readings.

- Commercial Office Tower, Tokyo: Retrofitted entrances with advanced PVC sealing strips, which halved interior dust ingress and contributed to a 26% improvement in air quality metrics, confirmed by third-party environmental audits.

- Pharmaceutical Cleanrooms, Basel: Customized seamless PVC sealing profiles ensured zero pass-through of particulate matter at controlled access points, enabling the facility to retain its ISO Class 5 certification during an intensive six-month validation period.

These cases highlight not only reduced operational costs and repairs, but also regulatory and qualitative enhancements following PVC-based sealing upgrades.

Guidelines for Selecting the Ideal Flexible PVC Sealing Strip

Choosing the optimal sealing strip involves examining several core factors:

- Environment and Load: Evaluate exposure to moisture, chemicals, UV rays, and frequency of use to prioritize tear resistance and longevity as needed.

- Installation Constraints: Assess available manpower and downtime windows; tool-free strips accelerate workflows for occupied buildings or tight schedules.

- Target Performance Metrics: Align product specification with standards for air, water, sound insulation, and energy efficiency. For doors, flexible door bottom sealing strips tested up to 35dB sound reduction may be preferred for high-traffic or acoustic-sensitive venues.

- Compliance Requirements: Ensure relevant approvals such as RoHS, REACH, ISO are documented for use in healthcare, food, or pharma sectors.

- Design and Aesthetics: Balance technical features with design integration—color, profile, and invisibility for public-facing applications.

Consulting with reputable manufacturers early in the specification phase often results in substantial lifecycle savings and improved project outcomes.

Outlook: Future Trends of Flexible PVC Sealing Strip in Modern Construction

As sustainability and advanced building automation evolve, flexible pvc sealing strip manufacturers invest increasingly in recyclable compounds and integration-ready smart seals equipped with embedded sensors. Current forecasts predict the global market for flexible sealants could surpass $2.1 billion by 2028, with PVC-based products leading due to their easy processing, formulation flexibility, and continuing cost-effectiveness. Partnerships among building solution providers, architects, and industrial designers are accelerating product innovation, from antimicrobial coatings to digitally traceable batches ensuring quality assurance. Given the mounting pressure for buildings to achieve higher environmental and performance certifications, flexible pvc sealing strips are likely to cement their role as the backbone of resilient, healthy, and low-maintenance modern structures.

(flexible pvc sealing strip)

FAQS on flexible pvc sealing strip

Q: What is a flexible PVC sealing strip?

A: A flexible PVC sealing strip is a pliable, durable strip made from polyvinyl chloride, designed for sealing gaps. It provides an effective barrier against water, dust, and air. It is commonly used in various doors, windows, and bathroom installations.

Q: Where can flexible bath sealing strips be used?

A: Flexible bath sealing strips are ideal for sealing gaps around bathtubs, shower trays, and sinks. They help prevent water leaks and reduce the risk of mold growth. Their flexibility ensures a snug fit on curved or uneven surfaces.

Q: How do I install a flexible door bottom sealing strip?

A: To install a flexible door bottom sealing strip, simply measure and cut the strip to fit, then press or stick it to the bottom of your door. Some models come with adhesive backing for easy application. This helps block drafts, dust, and insects from entering.

Q: Are flexible PVC sealing strips waterproof?

A: Yes, flexible PVC sealing strips are designed to be waterproof. They are specifically made to prevent water ingress in areas like bathrooms, kitchens, and entry doors. Their flexible nature ensures a tight and reliable seal.

Q: Can flexible PVC sealing strips be cut to custom lengths?

A: Absolutely, flexible PVC sealing strips can be easily cut with household scissors or a utility knife. This allows you to create a custom fit for your specific needs. Simply measure, cut, and apply as required.