Okt . 14, 2024 06:46 Back to list

grey epdm rubber sheet

The Versatility of Grey EPDM Rubber Sheets

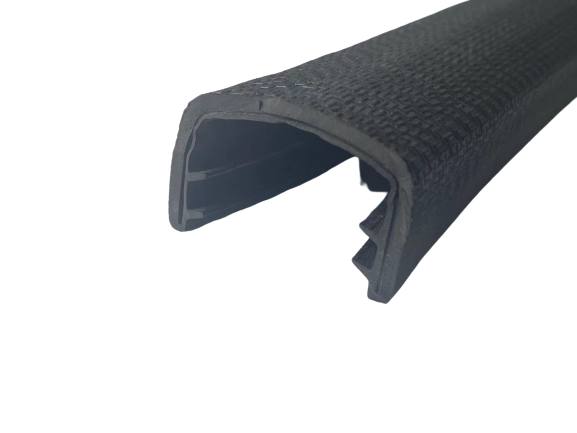

EPDM (Ethylene Propylene Diene Monomer) rubber is a synthetic polymer that has garnered significant attention in various industries due to its unique properties. Among the various types of EPDM sheets available, grey EPDM rubber sheets stand out for their aesthetic appeal and functional attributes. This article explores the features, applications, and benefits of grey EPDM rubber sheets, highlighting their versatility in different sectors.

Properties of Grey EPDM Rubber

Grey EPDM rubber sheets are characterized by their excellent weather resistance, UV stability, and ozone resistance. These properties make them suitable for outdoor applications where exposure to sunlight and harsh weather conditions is prevalent. The inherent flexibility and elasticity of EPDM rubber allow it to maintain its shape and resist wear and tear, making it a reliable choice for many industrial applications.

Another noteworthy feature of grey EPDM sheets is their thermal stability. They can withstand a wide range of temperatures, typically from -40°F to 212°F (-40°C to 100°C), without losing their physical properties. This temperature resilience makes them ideal for environments where extreme conditions are common, such as automotive and construction sectors.

Applications of Grey EPDM Rubber Sheets

1. Roofing Systems Grey EPDM rubber sheets are widely used in roofing applications due to their waterproof properties. They serve as effective membranes for flat roofs, helping to prevent leaks and water damage. The grey color also contributes to energy efficiency by reflecting sunlight, reducing heat absorption, and minimizing cooling costs.

2. Automotive Industry In the automotive sector, grey EPDM rubber sheets are utilized for gaskets, seals, and insulation. Their ability to resist high temperatures and various chemicals makes them ideal for automotive applications, extending the lifespan of vehicle components while ensuring optimal performance.

grey epdm rubber sheet

3. Industrial Applications Many industries benefit from using grey EPDM rubber sheets for manufacturing products that require durability and flexibility. These sheets are often employed in conveyor systems, vibration dampening, and as protective coverings for machinery and equipment.

4. Consumer Products In the consumer market, grey EPDM rubber sheets are used in a variety of applications, from mats and flooring solutions to protective padding in sports equipment. Their non-slip surface and cushioning properties make them suitable for creating safe and comfortable environments.

Benefits of Grey EPDM Sheets

One of the primary benefits of grey EPDM rubber sheets is their low maintenance requirements. Their resistance to weathering ensures longevity, reducing the need for frequent replacements. Additionally, their eco-friendly characteristics make them a sustainable choice, as they can be recycled and repurposed.

Furthermore, grey EPDM rubber sheets can easily be cut, shaped, and installed, offering versatility in design and application. Whether used in large-scale roofing projects or small automotive components, their adaptability meets the demands of various industries.

Conclusion

Grey EPDM rubber sheets are a valuable material with a wide range of applications. Their durability, weather resistance, and aesthetic appeal make them an excellent choice for both industrial and consumer products. As more industries recognize the benefits of using high-quality synthetic rubber, grey EPDM rubber sheets are likely to play an increasingly important role in development and innovation across various sectors. Whether for roofing, automotive parts, or consumer goods, the versatility of grey EPDM is undeniable, making it a material worth considering for future projects.