Nov. . 16, 2024 18:31 Back to list

silicone rubber door and window sealing strip factory

Exploring the Benefits of Silicone Rubber Door and Window Sealing Strips

When it comes to maintaining energy efficiency and comfort within our homes or commercial spaces, one often overlooked but critically important component is the sealing around doors and windows. A high-quality silicone rubber sealing strip can make all the difference. As we delve into the advantages and manufacturing processes of silicone rubber door and window sealing strips, we’ll uncover why they are a staple in the construction and renovation of modern buildings.

What are Silicone Rubber Sealing Strips?

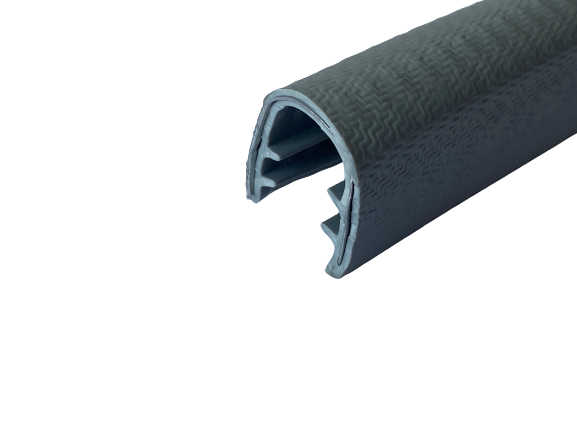

Silicone rubber sealing strips are flexible components designed to fill gaps around doors and windows. Their primary function is to prevent the entry of external elements like air, water, dust, and insects, while also ensuring that internal conditions remain stable. This is particularly important in climates that undergo extreme temperatures or frequent weather changes.

Silicone rubber is chosen for these sealing strips due to its superior properties. Unlike traditional rubber, silicones are more resilient to UV rays, ozone, and extreme temperatures, making them suitable for both indoor and outdoor applications. Their durability means that they can withstand wear and tear, maintaining their effectiveness over time.

Manufacturing Process of Silicone Rubber Sealing Strips

The production of silicone rubber sealing strips involves several key steps

1. Material Selection The process begins with the selection of high-quality silicone elastomers, which determine the final product's properties such as flexibility, durability, and resistance to environmental factors.

2. Compounding The raw silicone is mixed with various additives, including colorants, fillers, and curing agents. This stage is crucial as it enhances the physical properties of the material to meet specific application requirements.

3. Molding Once the silicone compound is prepared, it is placed into molds to give it the desired shape and dimensions. This could range from standard sizes to custom designs depending on customer specifications.

4. Curing The molded silicone is then cured through a heat or cold process. Curing is essential as it transforms the mixture into a robust elastomer capable of withstanding stress and environmental exposure.

silicone rubber door and window sealing strip factory

5. Quality Control After curing, each batch of sealing strips undergoes rigorous testing to ensure they meet industry standards. This includes evaluating their tensile strength, elasticity, and resistance to various factors.

6. Packaging Finally, the finished sealing strips are packaged for distribution to clients around the globe.

Advantages of Using Silicone Rubber Sealing Strips

1. Energy Efficiency One of the most significant advantages of using silicone rubber sealing strips is energy efficiency. By effectively sealing gaps, they prevent heated or cooled air from escaping the interior spaces of buildings, leading to lower energy bills.

2. Weather Resistance Silicone rubber's resistance to extreme temperatures and UV rays ensures that sealing strips remain effective in varying weather conditions. This longevity reduces the need for frequent replacements.

3. Easy Installation Most silicone sealing strips come with adhesive backing or can be easily fitted into existing channels without the need for specialized tools. This simplifies the installation process for both builders and homeowners.

4. Versatile Applications Silicone rubber sealing strips are versatile and can be used in a variety of contexts, including residential, commercial, and industrial settings. Whether it's for windows, doors, or even vehicles, their adaptability makes them an essential accessory.

5. Aesthetic Appeal Available in different colors and designs, silicone sealing strips can enhance rather than detract from the visual appeal of a building, blending seamlessly into any environment.

Conclusion

In conclusion, silicone rubber door and window sealing strips are a vital component in enhancing the energy efficiency, durability, and overall quality of building structures. Their unique properties and manufacturing processes exemplify the advancements in material science that cater to modern construction needs. Investing in high-quality sealing strips not only helps in maintaining a comfortable indoor environment but also contributes to long-term savings in energy costs. As sustainability and efficiency become increasingly important in construction, the role of silicone rubber sealing strips will undoubtedly continue to grow.