Δεκ . 25, 2024 22:18 Back to list

1 mm epdm rubber sheet

The Versatile Applications of 1% 20 mm EPDM Rubber Sheets

EPDM rubber, short for Ethylene Propylene Diene Monomer, is a synthetic rubber that has gained significant popularity due to its impressive durability, flexibility, and resistance to extreme weather conditions. Among various thickness options, 20 mm EPDM rubber sheets, especially those with a 1% composition contributing to specific characteristics, are finding applications across various industries. This article explores the unique properties of these sheets and their multifaceted applications.

Exceptional Properties of EPDM Rubber Sheets

The 1% formulation in 20 mm EPDM rubber sheets refers to the specific additives included in the compound to enhance certain properties. Typically, these additives can improve the rubber's tensile strength, increase its resistance to ultraviolet (UV) radiation, and enhance its performance in extreme temperatures, ranging from -40°F to +250°F. This versatility makes EPDM suitable for outdoor applications where exposure to the elements is a concern.

Additionally, EPDM rubber is inherently non-toxic and environmentally friendly, further elevating its appeal for many manufacturers. It is also resistant to ozone degradation, which means it will not crack or deteriorate when exposed to natural atmospheric conditions. This durability translates into long service life, reducing the need for frequent replacements and minimizing maintenance costs.

Applications in Various Industries

1. Construction Industry One of the most common applications for 20 mm EPDM rubber sheets is in the construction sector. These sheets can serve multiple purposes, from roofing materials to waterproofing membranes. In flat and low-slope roofing systems, EPDM provides excellent weather resistance and an effective barrier against water infiltration. This capability helps protect structures from potential water damage, thereby extending their lifespan.

1 mm epdm rubber sheet

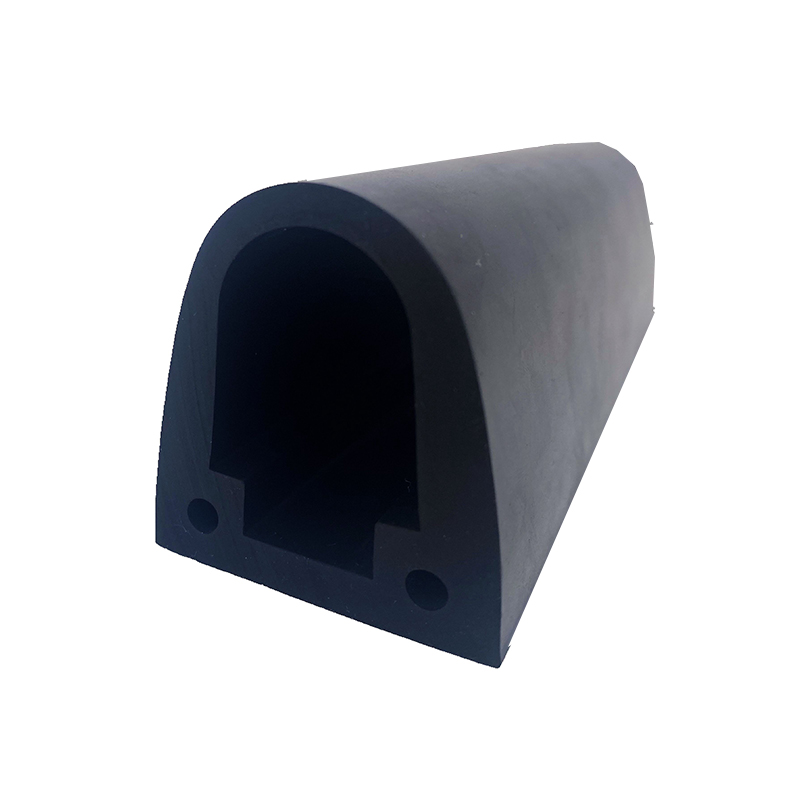

2. Automotive Sector EPDM rubber sheets are widely used in the automotive industry, where they contribute to the production of various seals and gaskets. Their resistance to heat and aging ensures that these components maintain their integrity over time, providing reliable performance in high-stress environments. This property is particularly essential for parts exposed to engine heat or harsh weather conditions.

3. Marine Applications The marine industry also benefits from the use of EPDM rubber sheets. The material's resistance to saltwater, UV rays, and extreme temperatures makes it an ideal choice for boat covers, dock bumpers, and seals. These applications require materials that can endure harsh marine environments while maintaining their structural integrity, which EPDM readily provides.

4. Industrial Uses In industrial settings, 20 mm EPDM rubber sheets can serve as protective mats, vibration dampers, or soundproofing materials. Their ability to absorb shock and reduce noise levels makes them suitable for machinery and equipment areas where sound attenuation and protection from vibrations are necessary.

5. Agricultural Sector The agricultural industry also utilizes EPDM rubber sheets for various applications, such as waterproof covers and liners for irrigation systems. Their resistance to wear and tear from exposure to fertilizers and chemicals makes them an excellent choice for ensuring longevity and effectiveness in agricultural practices.

Conclusion

The 1% 20 mm EPDM rubber sheet stands out as an exceptionally versatile material with applications spanning multiple industries. Its unique combination of durability, flexibility, and resistance to environmental factors makes it an ideal choice for construction, automotive, marine, industrial, and agricultural applications. As industries continue to demand reliable materials that can withstand challenging conditions, the importance and usage of EPDM rubber sheets are only expected to grow, solidifying their role in modern manufacturing and construction processes.