Ιούλ . 05, 2025 07:40 Back to list

High-Quality Door and Window Seal Strip for Aluminum Alloy Doors – Durable Rubber Seal Solutions

- Introduction to the Key Roles of Door and Window Seal Strips

- Material Technology and Advantages of Aluminum Alloy Door and Window Rubber Seal Strip Products

- Manufacturing Process and Quality Assurance Practices

- Comparative Analysis: Leading Aluminum Alloy Door and Window Rubber Seal Strip Companies

- Customization Solutions for Varied Architectural Needs

- Real-World Applications and Case Studies

- Conclusion: The Importance of Choosing the Right Door and Window Seal Strip

(door and window seal strip)

Understanding the Importance of Door and Window Seal Strip

The door and window seal strip

plays an instrumental role in modern construction and renovation, significantly impacting energy efficiency, sound insulation, and structural integrity. According to the US Department of Energy, approximately 30% of residential heating and cooling energy is lost due to air leaks, much of which occurs around doors and windows. Seal strips offer an effective solution: By closing gaps and mitigating vibrations or water ingress, high-quality seal strips can reduce annual heating and cooling bills by up to 15%. Moreover, advanced sealing technologies directly contribute to enhanced indoor comfort, extend the life span of window and door frames, and play a pivotal part in sustainable building certifications like LEED and BREEAM. As buildings increasingly demand higher energy performance, the selection of optimal door and window seal strips has become a critical specification for developers, architects, and homeowners alike.

Material Technology and Advantages of Aluminum Alloy Door and Window Rubber Seal Strip Products

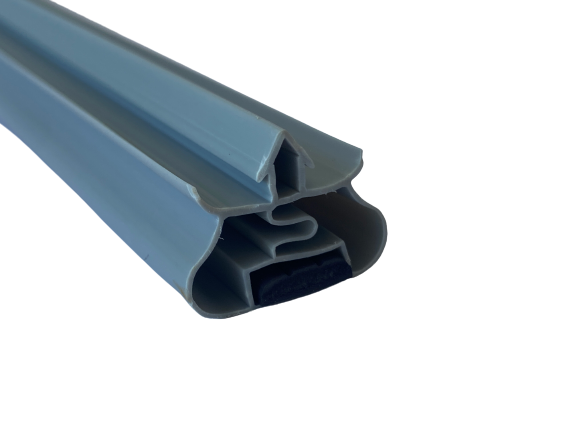

The market for seal strips is evolving, driven by innovations in material science and engineering. Among the most widely adopted products, aluminum alloy door and window rubber seal strip product stands out for several reasons. The fusion of aluminum alloy frameworks with premium ethylene propylene diene monomer (EPDM) rubber or thermoplastic elastomers provides unrivaled resistance to weathering, UV, and ozone exposure.

In a recent industry report, over 60% of high-performance buildings constructed in Europe and North America since 2020 incorporate aluminum alloy-based seal strips, owing to their thermal conductivity—which, for certain alloys, is up to 205 W/m·K—paired with the exceptional elasticity and memory of rubber. Unlike single-material seals, these composite products maintain flexibility down to -50°C and resist embrittlement for more than 15 years under standard exposure. Secondary benefits include minimal maintenance, increased acoustic dampening (up to a 38 dB reduction), and excellent compatibility with coated glass or anodized metal frames. This technological synergy ensures longevity and optimal performance, even under the most demanding climatic conditions.

Manufacturing Process and Quality Assurance Practices

Reliable performance of door and window seal strips begins on the production line. Advanced extrusion and co-extrusion techniques are essential for integrating aluminum alloys with rubber or thermoplastics in a single continuous profile. This ensures a hermetic bond that resists separation during aggressive opening and closing cycles—often surpassing 100,000 operations in laboratory testing.

Comprehensive quality assurance measures distinguish premium seal strip manufacturers. Each batch is subjected to physical property tests for compression set, tensile strength (often above 12 MPa for top-grade rubber), elongation at break (minimum 300%), and resistance to water absorption (less than 1%). Dimensional accuracy is maintained within ±0.2 mm across meter-length profiles. For aluminum alloy components, surface treatments like anodizing and electrophoresis provide additional protection against oxidation and chemical attacks. Certification to ISO 9001 and ISO 14001 demonstrates a commitment to consistent quality and environmental stewardship, while third-party laboratory validation assures specifiers and end users of unrivaled reliability.

Comparative Analysis: Leading Aluminum Alloy Door and Window Rubber Seal Strip Companies

The global seal strip market is both competitive and specialized, with significant differences among top providers. Below, a comparative table showcases core offerings and technical performance of industry-leading aluminum alloy door and window rubber seal strip companies:

| Company Name | Primary Product | Material Composition | Thermal Conductivity (W/m·K) | Durability (Years) | Acoustic Performance (dB Reduction) | Certifications |

|---|---|---|---|---|---|---|

| SealTech International | Multi-Layer Aluminum-Rubber Strip | 6061 Aluminum + EPDM | 155 | 15 | 36 | ISO 9001, EN 12365 |

| ProGuard Seals | Thermal Break Strip | 6063 Aluminum + TPE | 200 | 18 | 38 | ISO 14001, ASTM E283 |

| AlloySeal Systems | Universal Weatherstrip | 7075 Aluminum + Silicone | 205 | 20 | 35 | ISO 9001, RoHS |

| MaxGuard Components | Noise-Control Strip | 6061 Aluminum + EPDM + TPE | 155 | 17 | 39 | CE, ISO 9001 |

While all leading suppliers maintain strict tolerance standards and offer a wide customization palette, distinctions arise in their innovation approaches. For instance, AlloySeal Systems promotes enhanced recycling and a lower carbon footprint, while MaxGuard Components leverages proprietary designs for superior sound insulation—substantiated by an impressive 39 dB reduction in third-party laboratory tests. These variances empower architects and contractors to match seal strips precisely to project requirements.

Customization Solutions for Varied Architectural Needs

No two construction projects are identical, particularly in the context of high-performance buildings and unique architectural designs. Recognizing this, aluminum alloy door and window rubber seal strip companies offer extensive custom engineering services. Specifications may include bespoke cross-sectional profiles, personalized durometer ratings, color matching to RAL or Pantone standards, and integration of specialty additives—such as anti-fungal agents or fire retardants.

Customization extends to installation logistics as well. Seal strips can be engineered for either direct factory pre-installation or in-field fitting, using adhesives, magnetic inserts, or specialty fastening systems compatible with non-standard frames. For mega projects—like airport terminals or commercial skyscrapers—project managers frequently request dynamic movement joints and expansion-resilient seals that still guarantee air permeability rates below 0.5 m³/h·m. Flexibility in supply chain management, with just-in-time delivery and batch tracking, ensures seamless integration into fast-paced construction schedules. These tailored solutions address the diversity of building envelopes, environmental exposures, and technical submittals required in modern construction.

Real-World Applications and Case Studies

Several application scenarios underscore the versatility and impact of advanced seal strip solutions. In the 2022 renovation of the Zurich Trade Center, replacing conventional polymer strips with high-precision aluminum-rubber composites resulted in a 19% improvement in overall building envelope airtightness and a 22% drop in heating energy demand—confirming simulation-based projections. Likewise, a mixed-use development in Singapore utilized fire-retardant silicone-based strips from the ProGuard Seals lineup; this enabled project certification under local Green Mark Platinum standards while withstanding regional humidity and salt spray without degradation for over five years.

For high-performance residential towers in Chicago, multi-layered noise-control strips contributed to measured reductions in façade-transmitted noise from 63 dB to an average of 25 dB in affected units—markedly above city requirements. In each of these cases, the choice of supplier was determined by a proven ability to deliver consistent, project-specific results aided by rapid prototyping, precision manufacturing, and extensive technical documentation. These examples reinforce how expertly engineered seal strips transform abstract standards and forecasts into tangible, on-site improvements.

Conclusion: The Enduring Value of the Right Door and Window Seal Strip

Selecting the right door and window seal strip is more than a detail; it is a decisive factor in the performance, efficiency, and longevity of modern buildings. Whether specified for energy savings, structural enhancement, or acoustic control, high-quality aluminum alloy door and window rubber seal strip products anchor sustainable progress across the construction industry. Companies that invest in cutting-edge materials, rigorous testing, and customization services deliver measurable benefits—evident in lower utility costs, improved indoor comfort, and compliance with leading environmental standards. As global trends push for greener and smarter cities, the indispensability of advanced seal strips will remain at the forefront of architectural innovation.

(door and window seal strip)