Μάι . 30, 2025 11:09 Back to list

EPDM Rubber Sheet Specifications Durable, Weather-Resistant Rolls

- Understanding EPDM Rubber Sheet Technical Properties

- Key Manufacturing Advantages in EPDM Production

- Technical Specification Comparison: Leading Producers

- Industry-Specific Formulation Requirements

- Custom EPDM Sheet Engineering Process

- Documented Performance in Extreme Environments

- Implementing EPDM Specifications in Projects

(epdm rubber sheet specification)

Comprehensive Guide to EPDM Rubber Sheet Specification Fundamentals

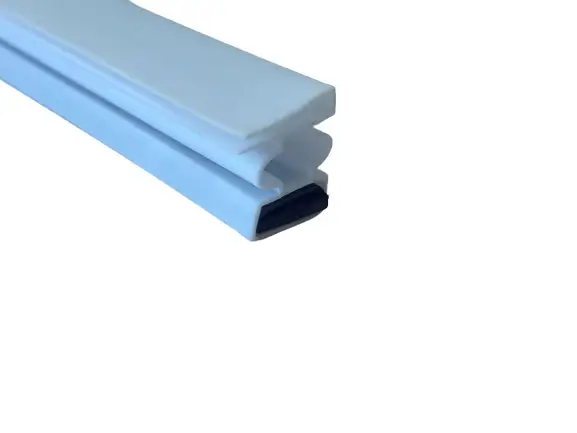

EPDM rubber sheets demonstrate exceptional weather resistance, withstanding temperatures from -50°C to +150°C. These synthetic rubber sheets maintain flexibility across industrial applications due to their stable polymer backbone structure. Key specification parameters include thickness tolerance (±0.2mm for premium grades), density (0.85 to 1.50 g/cm³), and durometer hardness (40 to 90 Shore A). Environmental certifications like NSF/ANSI 61 validate potable water safety, while UL listings confirm electrical insulation properties.

Manufacturing Advantages of Quality EPDM Products

Premium EPDM compounds incorporate patented antioxidant packages that extend service life beyond 25 years in UV-exposed applications. Modern vulcanization techniques achieve uniform cross-linking density within ±5% variation across the entire roll of rubber sheet EPDM rubber. Advanced calendering technology maintains dimensional stability within 0.3% linear expansion coefficient during temperature cycling. Leading producers now incorporate recycled EPDM content up to 40% without compromising physical properties, verified through ASTM D2000 testing.

Performance Comparison: Industry-Leading Producers

| Specification | Premium Brand A | Industrial Brand B | Economy Brand C |

|---|---|---|---|

| Tensile Strength (ASTM D412) | 17.2 MPa | 14.0 MPa | 9.8 MPa |

| Elongation at Break | 400% | 350% | 250% |

| Compression Set (22hr/100°C) | 15% | 25% | 35% |

| Weathering Resistance (ASTM G155) | 5000hr | 3000hr | 1500hr |

| Permeability (cm³·cm/cm²·s·Pa) | 0.6×10⁻¹³ | 1.2×10⁻¹³ | 3.8×10⁻¹³ |

Industry-Specific Formulation Requirements

Roofing membranes require carbon black masterbatches that achieve 98% UV absorption efficiency. Potable water applications demand FDA-compliant formulations with zero heavy metal accelerators. Electrical applications specify controlled volume resistivity between 10¹² and 10¹⁵ ohm·cm. Food processing environments require antimicrobial EPDM grades with efficacy against E.coli and Salmonella exceeding 99.9% reduction. Automotive weather seals utilize peroxide-cured compounds with consistent 55±5 IRHD hardness for optimal glass channel sealing.

Custom EPDM Sheet Engineering Protocol

Specialized production begins with compound rheology analysis using MDR (Moving Die Rheometer) to confirm cure characteristics. Custom-width rolls are calendered to tolerances of ±0.15mm across 2-meter widths. Post-curing treatments stabilize polymer networks through controlled thermal cycles in 30-meter continuous ovens. For EMI shielding applications, nickel-coated aramid fiber reinforcement increases conductivity to 10⁻¹ S/cm while maintaining 97% elongation properties.

Verified Performance in Critical Applications

EPDM roofing membranes at Dallas-Fort Worth Airport demonstrate zero cracking after 15 years of UV exposure and thermal cycling. Industrial gasketing in chemical processing plants withstands continuous exposure to 50% sulfuric acid at 80°C with less than 5% volume swell. Solar thermal panel seals maintain compression set below 20% after 8 years of service at 130°C operational temperatures. Below-grade waterproofing sheets installed in Chicago transit tunnels show 0% water transmission after 10 years in continuously submerged conditions.

Implementing Precise EPDM Rubber Sheet Specifications

Selecting appropriate EPDM rubber sheet specification requires cross-referencing ASTM standards with application-specific requirements. Factory production control systems should verify batch-to-batch consistency through statistical process control maintaining 6σ quality levels. Installation best practices require humidity-controlled storage at 40-60% RH before deployment. Third-party validation through accredited laboratories provides material traceability documentation, particularly crucial for roll of rubber sheet EPDM rubber used in critical infrastructure where material certificates must follow EN 10204 3.1 standards.

(epdm rubber sheet specification)

FAQS on epdm rubber sheet specification

Q: What are the standard specifications for EPDM rubber sheets?

A: EPDM rubber sheets typically range from 1.5mm to 12mm in thickness, with standard widths of 1m or 1.2m. They feature a hardness of 50-80 Shore A and meet ASTM D4637 standards for durability and weather resistance.

Q: What applications are EPDM rubber sheets suitable for?

A: EPDM rubber sheets are ideal for roofing membranes, HVAC seals, and waterproofing applications. Their ozone and UV resistance make them perfect for outdoor and industrial environments requiring temperature tolerance (-50°C to 150°C).

Q: What sizes do EPDM rubber sheet rolls come in?

A: Rolls of EPDM rubber sheets are commonly available in 10m, 20m, or 30m lengths. Custom roll lengths up to 50m can be manufactured for large-scale commercial projects.

Q: Does EPDM rubber sheet meet fire safety certifications?

A: Yes, EPDM sheets often comply with fire-resistance standards like UL 94-HB and BS 476. Specific formulations can achieve higher fire ratings (e.g., Class B1) for construction applications.

Q: How should I store EPDM rubber sheet rolls?

A: Store rolls vertically in cool, dry areas below 35°C, away from direct sunlight. Avoid stacking heavy materials on rolls to prevent deformation, and keep them 10cm above flooring to prevent moisture absorption.