Δεκ . 06, 2024 08:48 Back to list

epdm rubber roll

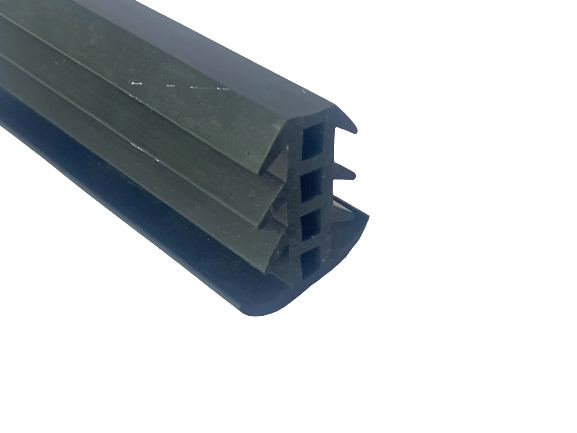

Exploring EPDM Rubber Rolls Versatile Solutions for Various Applications

Ethylene Propylene Diene Monomer (EPDM) rubber has gained significant popularity in various industries due to its exceptional properties and versatility. EPDM rubber rolls are widely used in applications ranging from automotive and construction to roofing and general industrial uses. This article delves into the characteristics, benefits, and applications of EPDM rubber rolls to better understand their importance in today’s production and construction environments.

What is EPDM Rubber?

EPDM rubber is a type of synthetic rubber that is known for its excellent resistance to heat, ozone, and weathering. It is a copolymer made of ethylene and propylene, with a small percentage of diene, which provides unsaturation and contributes to its unique set of properties. This robust chemical structure makes EPDM rubber an ideal choice for outdoor applications where exposure to harsh environmental conditions is a concern.

Key Characteristics of EPDM Rubber Rolls

1. Durability One of the standout features of EPDM rubber rolls is their durability. They can withstand extreme temperatures, ranging from -40°F to 140°F (-40°C to 60°C), without losing their physical properties. This makes them suitable for both hot and cold environments.

2. Weather Resistance EPDM does not degrade easily when exposed to UV rays, ozone, or moisture, ensuring a long service life even in outdoor applications. This weather resistance is particularly advantageous for roofing and automotive components.

3. Flexibility EPDM rubber rolls maintain excellent flexibility, making them easy to handle and install. This characteristic allows for a variety of applications, including seals and gaskets, where movement and compression are required.

4. Chemical Resistance EPDM demonstrates good resistance to many polar solvents, acids, and alkaline materials, although it is not suitable for use with oils or petroleum-based products. This makes it particularly useful in chemical processing environments.

5. Sound and Vibration Dampening The elastic properties of EPDM rubber provide effective sound insulation and vibration dampening, making it a preferred choice for applications requiring noise reduction.

epdm rubber roll

Applications of EPDM Rubber Rolls

EPDM rubber rolls find application in numerous sectors due to their favorable properties. Here are some significant uses

1. Roofing Membranes One of the most prominent applications of EPDM rubber is in roofing systems. EPDM rubber rolls are used as a durable membrane that provides waterproofing for commercial and residential buildings while also reflecting UV rays, thereby improving energy efficiency.

2. Automotive Components In the automotive industry, EPDM rubber is used for seals, gaskets, and hoses. Its resistance to heat and environmental factors ensures that these components perform reliably over a long period, enhancing vehicle durability.

3. Industrial Applications EPDM rubber rolls are utilized in vibration isolation mats, conveyor belt covers, and various handling systems in manufacturing and industrial settings. Their adaptability and resilience make them suitable for such rigorous conditions.

4. Consumer Products From playground surfaces to gardening hoses, EPDM rubber is increasingly found in consumer products where durability and safety are paramount. Its non-toxic composition also makes it safe for use in children’s toys and activities.

5. Electrical Insulation The electrical insulating properties of EPDM make it an excellent choice for applications requiring electrical safety, including wire and cable insulation.

Conclusion

EPDM rubber rolls represent a reliable and versatile material choice across a variety of industries. Their unique properties—such as weather resistance, durability, and flexibility—make them suitable for both demanding industrial applications and everyday consumer products. As industries continue to seek materials that combine performance with longevity, EPDM rubber will undoubtedly remain a go-to option for manufacturers and builders alike. Understanding the characteristics and applications of EPDM rubber rolls can help businesses make informed decisions when selecting materials for specific projects, ensuring that they meet performance standards while also maximizing cost-effectiveness.