Δεκ . 31, 2024 13:42 Back to list

epdm rubber sheet pricelist

Understanding EPDM Rubber Sheet Pricing

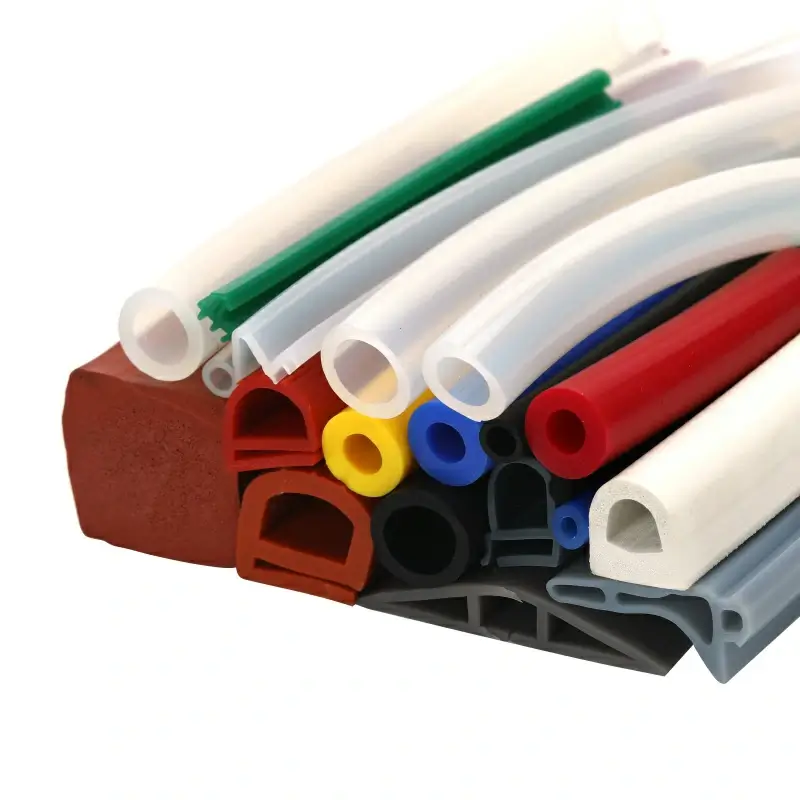

EPDM (Ethylene Propylene Diene Monomer) rubber is a versatile synthetic rubber known for its exceptional resistance to weathering, UV radiation, ozone, and high temperatures. As a result, EPDM rubber sheets are widely used across various industries such as automotive, construction, and manufacturing. The pricing of EPDM rubber sheets can vary significantly based on several factors, including the thickness, reinforcement, dimensions, and manufacturers. This article aims to provide insights into the pricing structure of EPDM rubber sheets.

Factors Affecting EPDM Rubber Sheet Prices

1. Thickness One of the primary factors influencing the price of EPDM rubber sheets is their thickness. Thicker sheets typically cost more due to the increased amount of raw material used in production. Sheets can range from a few millimeters to several centimeters in thickness, catering to different applications.

2. Material Quality The quality of the EPDM rubber used also affects pricing. Industrial-grade EPDM, which is designed for heavy-duty applications, will generally be more expensive than consumer-grade options. Manufacturers that offer enhanced durability, better UV resistance, and low-temperature flexibility may charge a premium for their products.

3. Dimensions The size of the EPDM rubber sheet plays a crucial role in determining its price. Larger sheets usually come with a higher price tag due to the larger volume of material. Custom sizes can also lead to increased costs, particularly if they require specialized manufacturing processes.

4. Reinforcement and Additives Some EPDM rubber sheets are reinforced with fabric or incorporate additives for specific applications, such as increased strength, better tear resistance, or chemical stability. These enhancements can raise the price due to their complex manufacturing process and the cost of additional materials.

epdm rubber sheet pricelist

5. Supplier and Brand Reputation Different suppliers and brands will have varying pricing strategies based on their market positioning, reputation, and manufacturing processes. Established brands with a history of quality may charge higher prices but could also offer assurance regarding the product's longevity and performance.

6. Order Quantity Bulk purchasing often results in lower per-unit costs. Many suppliers offer discounts for high-volume orders, which can be a significant factor for businesses that require large amounts of EPDM rubber sheets for their operations.

7. Market Trends The pricing of raw materials can fluctuate based on market demand, economic conditions, and availability. Keeping an eye on these market trends can provide insights into potential changes in EPDM rubber sheet pricing.

Typical Price Range

As of late 2023, the cost of EPDM rubber sheets typically ranges from $1 to $5 per square foot. However, specialty sheets can exceed this range, especially those designed for specific applications like roofing or automotive components. It’s advisable for buyers to compare various suppliers to find the best deals that meet their quality and performance requirements.

Conclusion

When considering the purchase of EPDM rubber sheets, understanding the factors that influence pricing is essential. By evaluating thickness, material quality, dimensions, reinforcement, supplier reputation, order quantity, and market trends, buyers can make informed decisions that best suit their needs. Whether for individual projects or large-scale manufacturing requirements, EPDM rubber sheets offer excellent durability and versatility, making them a valuable investment in various applications.