Φεβ . 08, 2025 02:00 Back to list

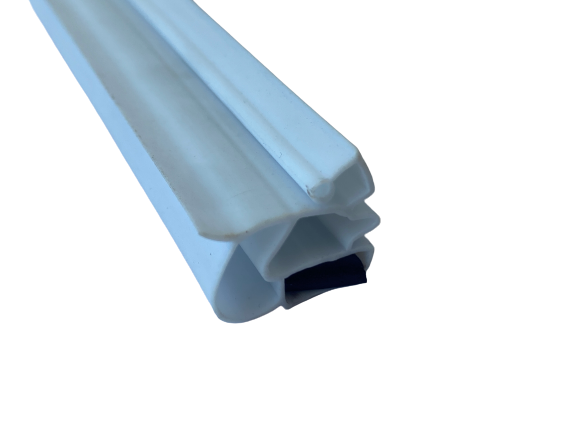

high quality epdm automotive fuel tank gasket

Navigating the intricate landscape of automotive components, the importance of high-quality EPDM (ethylene propylene diene monomer) rubber gaskets, particularly for fuel tanks, cannot be overstated. Professionals in the automotive industry understand that the reliability and safety of vehicles heavily depend on the quality of their parts. This is why EPDM gaskets, renowned for their durability and performance, are an essential component in fuel tank systems, ensuring optimal sealing and efficient functionality.

Authoritativeness in the automotive industry often links back to the quality standards adhered to during manufacturing. EPDM gaskets for fuel tanks should comply with international standards such as ASTM D2000, which specifies the physical and chemical properties of vulcanized rubber. Car manufacturers and automotive component suppliers recognize compliance with such standards as a testament to the product’s quality and reliability. When choosing EPDM gaskets, opting for products manufactured by companies with ISO 9001 certification further enhances their credibility, ensuring that production processes meet stringent quality management criteria. Reflecting on trustworthiness, consider the real-world applications and testimonials surrounding high-quality EPDM gaskets. Extensive in-field testing and consumer reports consistently underscore their capacity to perform under demanding conditions. Customers often cite enhanced vehicle performance, fewer maintenance-related issues, and long-term cost benefits when using these gaskets. Feedback from automotive engineers and maintenance experts also highlights the ease of installation and consistent performance of EPDM gaskets compared to alternative materials, which sometimes require more frequent replacements. Ultimately, investing in high-quality EPDM automotive fuel tank gaskets translates to bolstered vehicle efficacy, reduced environmental impact, and enhanced safety for consumers. As advancements in automotive technology persist, the role of durable, reliable components like EPDM gaskets become increasingly vital. For manufacturers and maintenance providers aiming to deliver excellence, these gaskets offer an unmatched balance of performance, resilience, and long-term value.

Authoritativeness in the automotive industry often links back to the quality standards adhered to during manufacturing. EPDM gaskets for fuel tanks should comply with international standards such as ASTM D2000, which specifies the physical and chemical properties of vulcanized rubber. Car manufacturers and automotive component suppliers recognize compliance with such standards as a testament to the product’s quality and reliability. When choosing EPDM gaskets, opting for products manufactured by companies with ISO 9001 certification further enhances their credibility, ensuring that production processes meet stringent quality management criteria. Reflecting on trustworthiness, consider the real-world applications and testimonials surrounding high-quality EPDM gaskets. Extensive in-field testing and consumer reports consistently underscore their capacity to perform under demanding conditions. Customers often cite enhanced vehicle performance, fewer maintenance-related issues, and long-term cost benefits when using these gaskets. Feedback from automotive engineers and maintenance experts also highlights the ease of installation and consistent performance of EPDM gaskets compared to alternative materials, which sometimes require more frequent replacements. Ultimately, investing in high-quality EPDM automotive fuel tank gaskets translates to bolstered vehicle efficacy, reduced environmental impact, and enhanced safety for consumers. As advancements in automotive technology persist, the role of durable, reliable components like EPDM gaskets become increasingly vital. For manufacturers and maintenance providers aiming to deliver excellence, these gaskets offer an unmatched balance of performance, resilience, and long-term value.