Δεκ . 31, 2024 02:25 Back to list

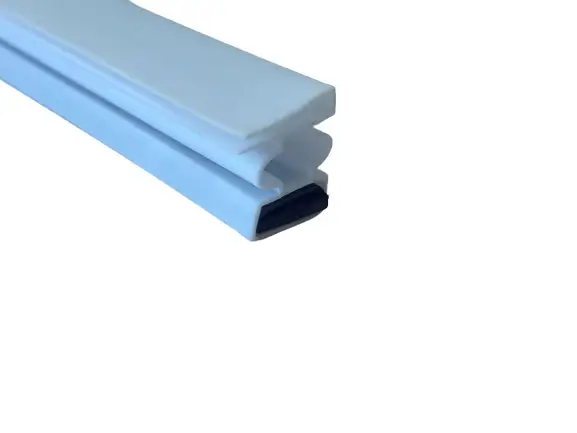

oem epdm rubber sheet

Understanding OEM EPDM Rubber Sheets

EPDM rubber, or Ethylene Propylene Diene Monomer, is a versatile synthetic rubber that has gained significant popularity across various industries. Known for its excellent weatherability, ozone resistance, and ability to withstand extreme temperatures, EPDM rubber is a preferred choice for many applications. When we refer to OEM EPDM rubber sheets, we are discussing Original Equipment Manufacturer (OEM) products made specifically for different uses and technical specifications.

What is EPDM Rubber?

EPDM rubber is a copolymer that consists of ethylene, propylene, and a diene monomer. This unique combination gives it properties that are superior to natural rubber, particularly in outdoor and demanding applications. EPDM’s resistance to weathering, UV radiation, and heat makes it suitable for products exposed to the elements. Furthermore, EPDM is known for its impressive resistance to oxidation and aging, which ensures a longer life span for the products made from it.

Advantages of OEM EPDM Rubber Sheets

1. Custom Specifications OEM manufacturers can tailor EPDM rubber sheets to meet specific requirements related to thickness, size, and performance characteristics. This customization is crucial for industries that need precise materials for their products.

2. Versatility EPDM rubber sheets can be used in a variety of applications, including roofing, automotive components, seals, and gaskets. Their adaptability makes them a popular choice in construction, automotive, and industrial sectors.

3. Durability One of the standout features of EPDM is its durability under a wide range of climatic conditions. It can perform effectively in both extremely low and high temperatures, making it an excellent choice for outdoor applications.

4. Chemical Resistance EPDM is resistant to a range of chemicals, including acids and alkalis. This property makes it suitable for applications in chemical processing and storage, where exposure to various substances is a concern.

oem epdm rubber sheet

5. Cost-Effectiveness While premium materials often come with a high price tag, OEM EPDM rubber sheets offer a balance of affordability and performance. Their long lifespan can lead to lower overall costs by reducing the frequency of replacement.

Applications of OEM EPDM Rubber Sheets

OEM EPDM rubber sheets find applications across numerous industries

- Construction EPDM is frequently used in roofing systems due to its waterproof qualities. EPDM roofing membranes are popular because they can easily conform to various shapes and resist environmental stressors.

- Automotive In the automotive industry, EPDM rubber sheets are used for seals, gaskets, and weatherstripping. They help provide insulation and protect against the elements, enhancing vehicle durability and performance.

- HVAC In heating, ventilation, and air conditioning (HVAC) systems, EPDM rubber sheets are employed to create seals and gaskets that play a critical role in maintaining efficiency and preventing leaks.

- Manufacturing In the manufacturing sector, EPDM rubber is used in machinery and equipment where flexibility and resistance to wear and tear are necessary.

Conclusion

As industries continue to evolve, the demand for high-quality materials like OEM EPDM rubber sheets is expected to grow. Their unique combination of properties and adaptability makes them an invaluable resource across various fields. When considering materials for specific applications, understanding the advantages and versatility of EPDM rubber is essential. Whether used for construction, automotive, or industrial purposes, OEM EPDM rubber sheets provide solutions that meet performance, durability, and cost-effectiveness standards. Investing in high-quality EPDM products can lead to enhanced operational efficiency and prolonged product life spans, making them a worthwhile addition to any industrial supply chain.