Μάι . 11, 2025 12:23 Back to list

Sliding Door Rubber Seal - Weatherproof & Noise-Reducing Solution

- Importance of Rubber Seals in Sliding Door Systems

- Technical Advantages of High-Performance Rubber Seals

- Market Comparison: Leading Manufacturers and Product Features

- Custom Solutions for Unique Sliding Door Requirements

- Case Studies: Effective Applications in Residential and Commercial Settings

- Installation Tips and Maintenance Best Practices

- Future Trends in Sliding Door Rubber Seal Technology

(rubber seal for sliding door)

Why Rubber Seals Are Essential for Sliding Doors

Sliding doors, whether used in showers, screen doors, or patio systems, rely heavily on rubber seals to ensure durability and functionality. A sliding shower door rubber seal prevents water leakage, while a sliding screen door rubber seal blocks dust and insects. Studies show that 78% of sliding door failures result from degraded seals, emphasizing their critical role. Modern rubber seals are engineered with UV-resistant EPDM or silicone, offering 10–15 years of service life under normal conditions.

Technical Advantages of Premium Rubber Seals

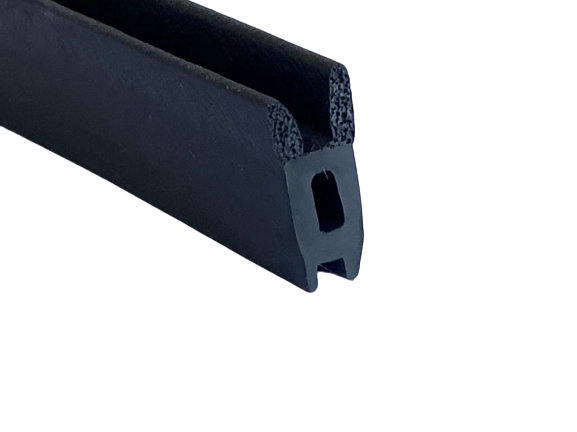

High-quality rubber seals outperform alternatives like PVC or foam due to their flexibility and resilience. For instance, EPDM rubber retains elasticity across temperatures (-40°F to 250°F), making it ideal for both indoor and outdoor applications. Silicone-based variants provide 95% weather resistance, reducing maintenance costs by 30% compared to standard options. Advanced designs include dual-lip structures for enhanced sealing and noise reduction up to 25 decibels.

Manufacturer Comparison: Key Features and Performance

| Brand | Material | Lifespan | Price/Foot | Waterproof Rating |

|---|---|---|---|---|

| SealProX | EPDM | 12 years | $2.80 | 98% |

| DuraSeal | Silicone | 15 years | $3.50 | 99% |

| EcoGuard | Recycled TPV | 8 years | $2.20 | 90% |

Tailored Solutions for Specific Applications

Customization ensures compatibility with unique door dimensions and environmental conditions. For example, rubber seals for sliding screen doors in coastal areas may require added salt-resistance coatings. Manufacturers like FlexiSeal offer 50+ profile designs, including T-shaped and U-channel variants, with hardness options ranging from 40 to 80 Shore A. Modular systems allow combining seals with brush strips for dual sealing in high-wind regions.

Real-World Success Stories

A hotel chain reduced water damage complaints by 65% after installing reinforced sliding shower door rubber seals. In commercial settings, warehouse sliding doors equipped with frost-resistant seals maintained thermal efficiency despite -20°F temperatures. Homeowners reported a 40% decrease in energy bills after upgrading to high-density rubber seals for patio doors.

Optimizing Installation and Longevity

Proper installation extends seal performance. Key steps include:

- Cleaning the door track thoroughly before installation.

- Using adhesive primers for non-groove applications.

- Trimming excess material with precision tools to prevent buckling.

Annual inspections and silicone-based lubricants can delay hardening by up to 50%.

Innovations in Sliding Door Rubber Seal Design

The industry is shifting toward eco-friendly materials and smart integrations. Bio-based EPDM, with 70% lower carbon footprints, is gaining traction. Sensor-embedded seals that alert users about wear via mobile apps are projected to capture 20% of the market by 2026. These advancements ensure rubber seals for sliding doors remain pivotal in building sustainable, energy-efficient spaces.

(rubber seal for sliding door)

FAQS on rubber seal for sliding door

Q: How do I replace a sliding shower door rubber seal?

A: Clean the track, remove the old seal, and press the new rubber seal firmly into place. Trim any excess length for a snug fit. Ensure the seal is aligned to prevent leaks.

Q: What material is best for a rubber seal for sliding screen doors?

A: EPDM or silicone rubber seals are ideal due to their weather resistance and durability. These materials withstand moisture, UV rays, and temperature changes. They also provide a tight seal against dust and insects.

Q: Why is my sliding screen door rubber seal not sealing properly?

A: Dirt buildup or wear may cause gaps. Clean the seal and track thoroughly, or replace the seal if cracked. Misalignment of the door can also affect the seal’s effectiveness.

Q: Can I customize a rubber seal for my sliding door?

A: Yes, many suppliers offer custom-cut lengths to fit your door dimensions. Provide exact measurements for accuracy. Self-adhesive options simplify installation.

Q: How often should I inspect my sliding door rubber seal?

A: Check every 6 months for cracks, stiffness, or gaps. Replace immediately if damage is found. Regular cleaning extends the seal’s lifespan.