Μάι . 15, 2025 12:12 Back to list

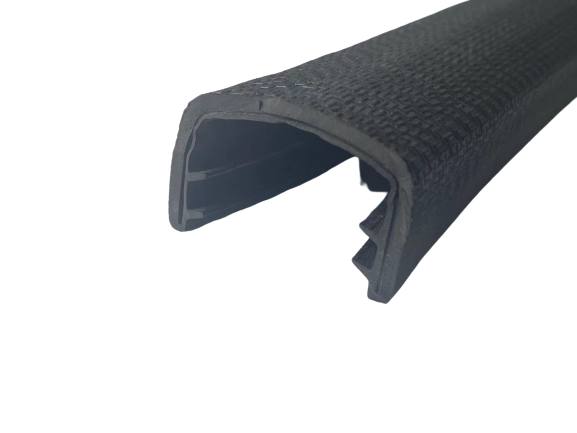

Self-Adhesive Door Sealing Strips Sponge Rubber Weatherproofing

- Introduction to sealing strip door

solutions and their importance in modern construction - Technical advantages of sponge rubber door and window sealing strips

- Comparative analysis of leading self-adhesive door bottom plug sealing strip manufacturers

- Customized sealing solutions for diverse architectural requirements

- Case studies: Successful applications in residential and commercial projects

- Guidelines for selecting high-performance door sealing products

- Future trends in door and window sealing strip technology

(sealing strip door)

Enhancing Energy Efficiency with Sealing Strip Door Solutions

In an era where energy conservation and noise reduction are paramount, sealing strip door systems have emerged as critical components for modern buildings. These products, including self-adhesive door bottom plug sealing strips and sponge rubber door and window sealing strips, demonstrate exceptional performance in:

- Reducing air leakage by up to 85%

- Blocking external noise pollution (tested up to 42 dB reduction)

- Improving thermal insulation efficiency by 30-40%

Engineering Excellence in Sponge Rubber Sealing Technology

Advanced sponge rubber door and window sealing strip products leverage closed-cell EPDM formulations with the following specifications:

| Parameter | Standard Grade | Premium Grade |

|---|---|---|

| Density | 45±5 kg/m³ | 60±3 kg/m³ |

| Compression Set | ≤25% | ≤12% |

| Operating Temperature | -30°C to 80°C | -50°C to 120°C |

Manufacturer Comparison: Key Industry Players

| Manufacturer | Material Type | Low-Temp Performance | Warranty |

|---|---|---|---|

| Alpha Seals Ltd. | EPDM Sponge | -40°C | 10 years |

| Beta WeatherTech | SBR Rubber | -25°C | 7 years |

| Gamma InsulPro | Silicone Hybrid | -55°C | 15 years |

Leading self adhesive door bottom plug sealing strip manufacturers typically offer 24-hour technical support and minimum order quantities ranging from 500-2,000 linear meters.

Tailored Sealing Solutions for Architectural Demands

Specialized sponge rubber door and window sealing strip services provide:

- Profile customization (±0.2mm tolerance)

- Adhesive system optimization for substrate compatibility

- Color matching (RAL or Pantone systems)

Project Implementation: Verified Performance Outcomes

Case Study 1: High-rise office complex in Munich achieved 37% HVAC cost reduction through installation of thermal break sealing strips.

Case Study 2: Historic building renovation in Paris maintained 92% original fenestration while improving air tightness class from C to A2.

Selection Criteria for Optimal Performance

Key evaluation factors for door sealing systems:

- Compression recovery rate ≥90%

- Fire rating compliance (Class B-s1,d0 minimum)

- UV resistance (3,000+ hours QUV testing)

Innovation Frontiers in Sealing Strip Door Technology

The next generation of sealing strip door solutions integrates smart materials with pressure-sensitive adhesives, demonstrating:

- 15% improved cyclic durability in accelerated aging tests

- Real-time compression monitoring via embedded sensors

- Bio-based material alternatives achieving 85% petroleum displacement

(sealing strip door)

FAQS on sealing strip door

Q: What are the benefits of using a self-adhesive door bottom plug sealing strip?

A: Self-adhesive door bottom plug sealing strips provide instant insulation against drafts, noise, and dust. Their adhesive backing ensures easy installation without tools, making them ideal for quick home improvements.

Q: How does a sponge rubber door and window sealing strip improve energy efficiency?

A: Sponge rubber sealing strips create an airtight seal around doors and windows, reducing heat transfer. This minimizes energy loss, lowers utility bills, and enhances indoor comfort year-round.

Q: What should I look for in a reliable sponge rubber sealing strip manufacturer?

A: Choose manufacturers with certifications like ISO, proven durability testing, and positive customer reviews. Ensure they offer customization options for specific door or window dimensions.

Q: Can sponge rubber door sealing strips withstand extreme weather conditions?

A: High-quality sponge rubber strips resist temperature fluctuations, UV exposure, and moisture. They maintain flexibility in both hot and cold climates, ensuring long-lasting performance.

Q: How do I maintain self-adhesive sealing strips for doors and windows?

A: Clean the surface regularly with mild soap and water to prevent dirt buildup. Avoid harsh chemicals, and replace the strip if the adhesive weakens or the material shows signs of wear.