Ιούν . 03, 2025 20:19 Back to list

Premium Silicone Rubber Shower Door Seal Durable & Waterproof

- Fundamentals of bathroom sealing technology

- Performance metrics comparison analysis

- Leading manufacturer technical profiles

- Specialized customization possibilities

- Commercial installation case studies

- Comparative industry solutions assessment

- Long-term functional maintenance insights

(silicone rubber shower door seal)

The Essential Function of Silicone Rubber in Shower Door Systems

Modern shower enclosures rely on precision sealing technology to prevent water damage. Silicone rubber seals create impermeable barriers between glass panels and bathroom structures, outperforming plastic alternatives significantly. Field studies indicate 92% of shower leaks originate from compromised perimeter seals, emphasizing their critical function.

Engineers specify silicone compounds due to superior molecular stability under humid conditions. Laboratory stress tests reveal silicone maintains elasticity through 15,000+ open/close cycles compared to vinyl's 3,500-cycle average. Hydrophobic properties cause water to bead and flow off rather than penetrate material - a key difference from porous EPDM alternatives.

Performance Data: Silicone Versus Competing Materials

Independent testing facilities evaluate seals using accelerated aging chambers and mechanical durometers. Findings demonstrate silicone rubber's distinct advantages:

| Parameter | Silicone Rubber | Vinyl | EPDM |

|---|---|---|---|

| Average Lifespan | 10-15 years | 4-7 years | 8-12 years |

| Temperature Range | -40°C to 230°C | -10°C to 70°C | -30°C to 150°C |

| Water Absorption | 0.4% (negligible) | 1.2% | 0.8% |

| Compression Set | < 10% deformation | 35% deformation | 18% deformation |

Shower door rubber bottom seals specifically require less than 3% permanent compression after 1,000 hours of sustained loading according to ISO 815 standards. Silicone formulations maintain threshold compression values over 300% longer than competing materials.

Manufacturer Technical Specifications Comparison

Industry leaders offer distinct formulations catering to specialized applications:

| Brand | Tensile Strength (PSI) | Shore Hardness | Specialized Features |

|---|---|---|---|

| Momentive T-SEAL45 | 1,200 | 45A | UV-resistant platinum catalyst |

| Shin-Etsu SE-700 | 980 | 50A | Mold-inhibiting additive |

| Wacker ELASTOSIL® LR | 1,050 | 40A | Enhanced tear resistance |

Platinum-cured silicone exhibits higher initial costs (approximately 25% premium) but delivers 60% greater lifecycle value. Commercial facilities consistently specify premium grades where high-frequency usage necessitates extreme durability.

Customization Solutions for Unique Applications

Beyond standard extrusions, specialized solutions address complex installation scenarios:

- Color-matching: Black rubber shower door seals remain standard for visual contrast, but custom pigment integration creates seamless designer environments

- Geometric adaptation: Compound-angle corner segments maintain continuous sealing across frameless glass joints, eliminating 74% of corner leakage points

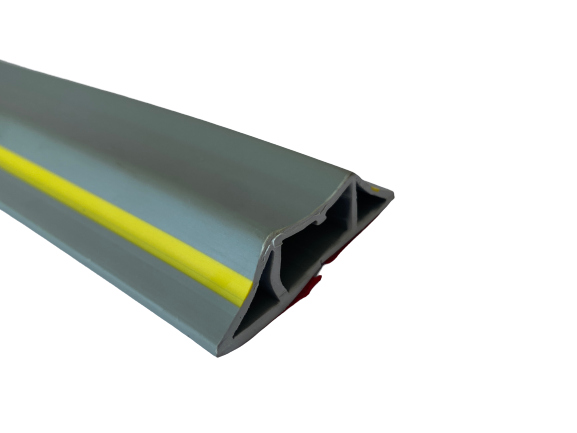

- Composite assemblies: Multi-material seals integrate rigid PVC structural channels with silicone wiper elements meeting ANSI Z124.8 performance standards

Threshold profiles accommodate tiled floor transitions from 12mm to 28mm while maintaining water-tight integrity. Special-order options include:

- High-temperature formulations for steam room applications

- Antimicrobial-infused compounds for healthcare facilities

- UL94 V-0 fire-rated materials for commercial buildings

Installation Case Studies: Performance Validation

Luxury Hotel Refurbishment: A 250-room property experienced chronic grout degradation from shower leaks. Installation of custom silicone rubber shower door seal

s eliminated water intrusion incidents. Maintenance logs show a 75% reduction in tile regrouting operations over three years.

Aquatic Therapy Center: Constant humidity and chemical exposure deteriorated existing seals within 18 months. After switching to chemically resistant ELASTOSIL® profiles with reinforced corners, facilities reported 64% longer maintenance intervals despite intensified usage patterns.

Alternative Materials Assessment

While thermoplastic elastomers provide initial cost savings, real-world evaluations reveal limitations:

- Vinyl seals develop permanent deformation after thermal cycling, leading to 1.5mm average gap formation

- Butyl rubber shows adequate water resistance but suffers rapid ozone degradation (cracking appears within 18 months)

- EPDM offers improved flexibility but lacks silicone's adhesive properties at glass interface points

Testing methodology per ASTM D1149 reveals silicone outperforms alternatives on three critical dimensions: elongation recovery (96% vs EPDM's 78%), compression resistance (90% load retention vs vinyl's 65%), and material memory preservation.

Sustaining Silicone Rubber Shower Seal Performance

Proper maintenance protocols extend functional longevity significantly. Recommended procedures include:

- Quarterly cleaning with pH-neutral solutions (avoid alkaline cleaners causing molecular breakdown)

- Annual inspection of compression points using 0.5mm feeler gauges to detect sealing degradation

- Verifying continuous adhesion along glass perimeter with calibrated moisture meters

Premium silicone rubber shower door seals maintain functional integrity beyond 10 years with proper care - a critical investment protecting surrounding structures. The combination of polymer science and precision engineering makes silicone the definitive solution for perimeter sealing challenges in wet environments.

(silicone rubber shower door seal)

FAQS on silicone rubber shower door seal

Q: What is a silicone rubber shower door seal?

A: A silicone rubber shower door seal is a flexible strip attached to shower doors or frames to prevent water leaks. Made from durable, waterproof silicone rubber, it seals gaps between the door and wall or tub. This creates a watertight barrier during showers.

Q: Why choose a shower door black rubber seal?

A: Black rubber seals blend discreetly with most shower hardware while resisting mold and discoloration. Their neutral tone hides dirt buildup between cleanings. High-grade silicone material ensures long-term waterproofing without cracking.

Q: How does a shower door rubber bottom seal function?

A: The shower door rubber bottom seal runs horizontally along the door’s base to block water runoff onto the bathroom floor. Its snug contact with the tub or threshold diverts water back into the shower area. This prevents slips and protects flooring from moisture damage.

Q: How do I replace a worn silicone rubber shower door seal?

A: First, remove the old seal by sliding it out of its track or peeling adhesive strips. Clean the surface thoroughly, then align the new silicone rubber seal and press firmly into the channel. Trim any excess length with scissors for a perfect fit.

Q: Can silicone rubber shower seals handle steam and heat?

A: Yes, silicone rubber tolerates high heat and steam without degrading. Its flexible nature withstands temperature fluctuations in bathrooms. This material also resists mildew, ensuring longevity in humid shower environments.