Dic . 01, 2024 13:49 Back to list

Car Window Rubber Seal Manufacturers for Quality and Durability

The Role of Car Window Rubber Seal Factories in Automotive Manufacturing

In the automotive industry, every component plays a vital role in ensuring the performance, safety, and comfort of a vehicle. One often-overlooked but crucial component is the rubber seal used around car windows. These seals, designed for both functionality and aesthetics, are manufactured in specialized factories dedicated to producing high-quality rubber products. This article will explore the significance of car window rubber seal factories in automotive manufacturing and their contribution to vehicle performance and passenger comfort.

The Importance of Rubber Seals

Rubber seals serve multiple purposes in a vehicle. They are primarily designed to prevent water, dust, and air from entering the car. This is particularly important for maintaining the interior environment of a vehicle, ensuring that passengers enjoy a comfortable ride free from external noise and elements. Additionally, rubber seals help reduce vibrations and rattling sounds, thus enhancing the overall driving experience.

Moreover, these seals play a significant role in vehicle safety. A proper seal ensures that windows and windshields adhere securely to the car frame, which is crucial during accidents. In such scenarios, well-fitted rubber seals can help maintain structural integrity, preventing glass from shattering and providing a protective barrier for occupants.

Manufacturing Process of Rubber Seals

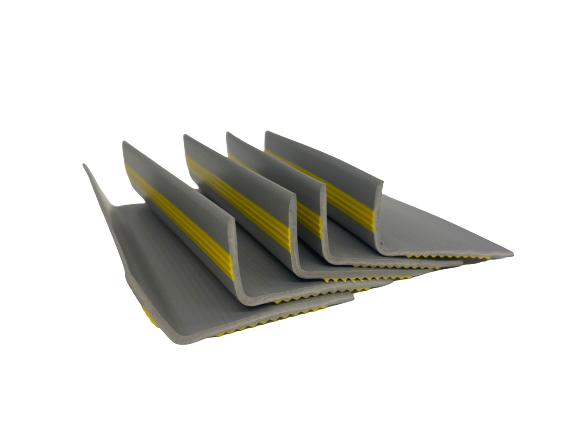

The production of rubber seals is a meticulous process that involves several stages. Car window rubber seal factories utilize advanced technology and precision engineering to ensure that each product meets stringent industry standards. The process typically begins with the selection of high-quality raw materials, which may include different types of synthetic rubber and additives. These materials are chosen based on their durability, weather resistance, and flexibility.

car window rubber seal factories

Once the materials are sourced, the production process commences with the mixing of raw materials to create a uniform compound. This mixture is then formed into the desired shape using various techniques such as extrusion or molding. Extrusion is a common method for creating long sections of seals, while molding is often used for producing specific shapes that conform to various window designs.

After forming, the seals undergo a curing process, where they are heated to enhance their properties. This vulcanization process is critical as it gives the rubber its elastic and durable characteristics. The final stage involves quality control, where each batch of seals is meticulously inspected for flaws or inconsistencies. Only those that pass rigorous quality checks are designated for use in automotive production.

Innovations in Seal Technology

As the automotive industry evolves, so does the technology used in rubber seal production. Car window rubber seal factories are now incorporating advanced materials and innovative manufacturing processes to improve the effectiveness and longevity of their products. For instance, the use of thermoplastic elastomers (TPE) is becoming increasingly common due to their excellent weather resistance and ability to withstand extreme temperatures.

Furthermore, factory automation is revolutionizing the production process. Automated machinery allows for greater precision and speed, reducing production times while maintaining high-quality standards. Additionally, the shift towards sustainable practices is prompting many factories to explore eco-friendly materials and recycling methods, aligning with the global push for greener manufacturing.

Conclusion

In conclusion, car window rubber seal factories play an essential role in the automotive manufacturing landscape. By producing high-quality seals, these factories contribute significantly to vehicle performance, safety, and passenger comfort. As technology continues to advance, the evolution of rubber seal manufacturing will likely lead to even greater innovations in the automotive sector. The commitment of these factories to quality and innovation ensures that vehicles are equipped with the best components, ultimately enhancing the driving experience for consumers around the world.