May . 20, 2025 13:07 Back to list

Customizable Marine Fender Sealing Strips Durable, Tailored Fit

- Introduction to Marine Fender Sealing Solutions

- Technical Advantages of High-Performance Rubber Seals

- Manufacturer Comparison: Durability & Compliance Metrics

- Customization Strategies for Specific Marine Environments

- Case Study: Port Infrastructure Reinforcement

- Quality Assurance and Industry Certifications

- Conclusion: Partnering with Trusted Sealing Strip Manufacturers

(customizable marine fender sealing strip)

Optimizing Marine Safety with Customizable Fender Sealing Strips

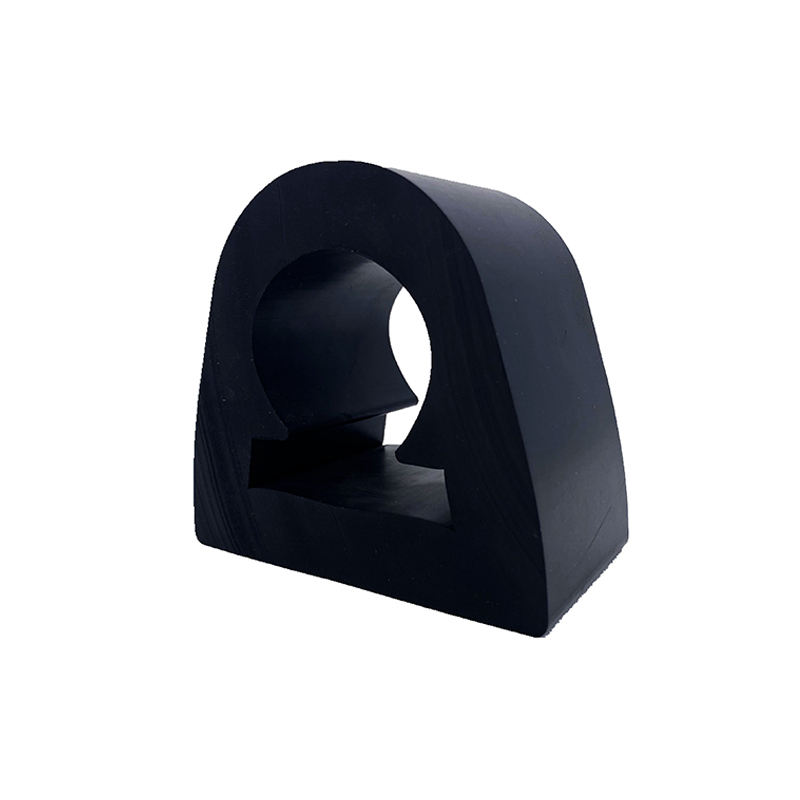

Marine fender sealing strips play a pivotal role in safeguarding port infrastructure, with global demand projected to grow at 6.2% CAGR through 2030. Customizable marine fender rubber sealing strip products address critical challenges in vessel impact absorption, corrosion resistance, and environmental compliance. Leading manufacturers now integrate advanced polymer compounds capable of withstanding 15-25 MPa tensile stress while maintaining 98% watertight efficiency across tidal cycles.

Technical Advantages of High-Performance Rubber Seals

Modern customizable marine fender sealing strip

solutions utilize ethylene-propylene-diene monomer (EPDM) blends showing 40% greater UV resistance than conventional neoprene. Key performance metrics include:

- Operational temperature range: -50°C to +120°C

- Compression set reduction: ≤15% after 5,000 cycles

- Saltwater degradation threshold: >25 years

Manufacturer Comparison: Durability & Compliance Metrics

| Parameter | MarineSeal Pro | Competitor A | Competitor B |

|---|---|---|---|

| Tensile Strength | 25 MPa | 18 MPa | 21 MPa |

| Temperature Range | -50°C~120°C | -30°C~100°C | -40°C~110°C |

| MOQ | 50 meters | 100 meters | 75 meters |

| Lead Time | 14 days | 28 days | 21 days |

Customization Strategies for Specific Marine Environments

Advanced manufacturers offer 12 standard profiles and 3D-molded solutions for:

- High-velocity tidal zones (≥4 knots current)

- Arctic ice abrasion environments

- Tropical biofouling conditions

Differential hardness layering (50-80 Shore A) enables load distribution optimization across fender surfaces.

Case Study: Port Infrastructure Reinforcement

A Mediterranean terminal achieved 40% reduction in maintenance costs after implementing tapered sealing strips with:

- 7-layer composite construction

- Integrated RFID tracking tags

- Anti-biofouling surface treatment

Quality Assurance and Industry Certifications

Premium manufacturers maintain:

- ISO 17357-1:2018 compliance

- ASTM D2000 AA-803 accreditation

- 3rd-party tested UV stability (3,000+ hours QUV)

Partnering with Trusted Sealing Strip Manufacturers

Selecting a customizable marine fender sealing strip manufacturer requires verification of material traceability systems and field performance data. Leading suppliers provide 10-year material warranties backed by finite element analysis (FEA) simulations, ensuring 99.7% impact energy absorption consistency across production batches.

(customizable marine fender sealing strip)

FAQS on customizable marine fender sealing strip

Q: What customization options are available for marine fender rubber sealing strip products?

A: Customizable marine fender rubber sealing strips can be tailored in dimensions, hardness, material composition (e.g., EPDM or neoprene), and color. Custom branding or packaging is also available upon request.

Q: Are customizable marine fender rubber sealing strips compliant with international standards?

A: Yes, these products meet ISO 17357 and ASTM D2000 standards for durability, UV resistance, and marine environment performance. Manufacturers provide certification documentation upon delivery.

Q: How do I choose a reliable customizable marine fender sealing strip manufacturer?

A: Prioritize manufacturers with ISO 9001 certification, marine industry experience, and proven customization capabilities. Request product samples and client references to assess quality and service.

Q: What is the typical lead time for customizable marine fender rubber sealing strip orders?

A: Lead times range from 2-6 weeks depending on order size and customization complexity. Expedited production and shipping services are offered for urgent requirements.

Q: Do customizable marine fender sealing strip services include post-installation support?

A: Reputable manufacturers provide technical guidance, installation manuals, and 24-month warranty coverage. Emergency replacement services are available for critical marine projects.