Dic . 21, 2024 23:09 Back to list

custom sponge rubber door and window seals are available factories

Custom Sponge Rubber Door and Window Seals A Comprehensive Guide

In today's world, ensuring energy efficiency and enhancing comfort within our homes and commercial spaces is paramount. One of the often-overlooked elements in achieving these goals is the quality of door and window seals. Custom sponge rubber door and window seals are increasingly becoming popular due to their durability, flexibility, and excellent sealing properties. In this article, we will explore the benefits of using these custom seals, the manufacturing process involved, and how to choose the right factory for your needs.

What are Custom Sponge Rubber Seals?

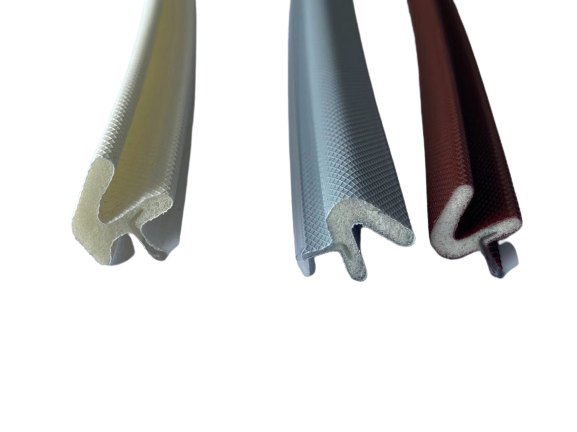

Custom sponge rubber seals are made from closed-cell sponge rubber, which is known for its lightweight and elastic properties. These seals are designed to fit snugly around doors and windows, preventing drafts, moisture, dust, and noise from entering the living or working environment. Tailored to specific dimensions, these seals can accommodate a variety of door and window styles, making them a versatile choice for both residential and commercial applications.

Advantages of Using Sponge Rubber Seals

1. Energy Efficiency One of the primary benefits of custom sponge rubber seals is their ability to create a barrier against air leakage. By ensuring that doors and windows are tightly sealed, these products play a significant role in reducing heating and cooling costs. Improved insulation leads to a more comfortable environment and lower energy bills, making it an investment that pays for itself over time.

2. Noise Reduction Sponge rubber seals are effective at minimizing sound transmission. Whether you live in a bustling city or a noisy neighborhood, these seals can help create a quiet and peaceful indoor atmosphere.

3. Moisture and Dust Barrier The closed-cell structure of sponge rubber makes it resistant to water absorption, preventing moisture from entering. This characteristic is especially beneficial in preventing mold growth and maintaining indoor air quality. The seals also keep out dust and allergens, contributing to a healthier living space.

4. Durability and Longevity Custom sponge rubber seals are designed to withstand various environmental conditions. They are resistant to aging, UV rays, and extreme temperatures, ensuring that they maintain their shape and functionality over time.

5. Easy Installation Most sponge rubber seals come with adhesive backing, making installation a straightforward process. They can be easily cut to size and affixed to the desired surfaces without the need for specialized tools.

The Manufacturing Process

The production of custom sponge rubber seals involves several steps to ensure that they meet specific quality standards and customer requirements

custom sponge rubber door and window seals are available factories

1. Material Selection Smart factories prioritize high-quality materials to ensure durability and performance. Advanced materials improve insulation properties and longevity.

2. Custom Design Customers can provide specifications including dimensions, shapes, and colors. The manufacturing process can be tailored to meet unique requirements, allowing for a perfect fit.

3. Cutting and Shaping Once designs are finalized, the sponge rubber is cut and shaped using precision machinery. This ensures consistent quality and accurate dimensions for each seal.

4. Quality Control Rigorous testing is conducted to ensure that the seals meet performance standards. This includes testing for air and water resistance and overall durability.

Choosing the Right Factory

When looking for a factory to supply your custom sponge rubber door and window seals, consider the following factors

1. Reputation and Experience Look for manufacturers with a strong track record and positive reviews. An experienced factory will have the capability to meet varying needs.

2. Customization Options Ensure the factory can provide the level of customization you require, whether in terms of size, shape, or material.

3. Quality Assurance A good manufacturer will have quality control processes in place to ensure the final product meets or exceeds expectations.

4. Customer Service Choose a factory that values communication and customer support. This will ease the process from order placement to delivery.

Conclusion

Custom sponge rubber door and window seals are an essential investment for enhancing energy efficiency, comfort, and the overall quality of your indoor environment. By understanding their benefits and knowing how to choose a reliable factory for production, you can significantly improve the insulation and aesthetic appeal of your space. Whether for a new construction, renovation, or simply upgrading existing seals, these custom solutions offer the flexibility and functionality needed in today’s market.