Nov . 24, 2024 07:12 Back to list

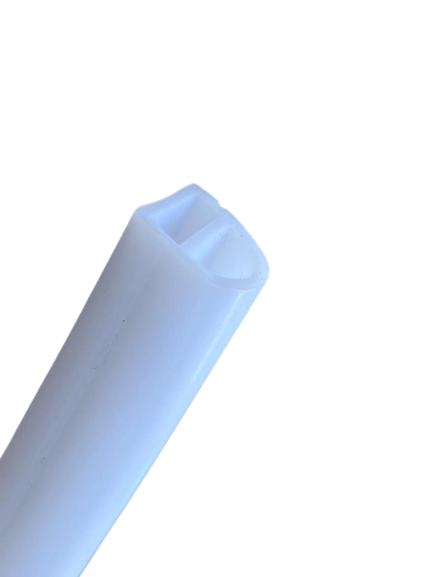

gum rubber roll

The Versatility and Applications of Gum Rubber Rolls

Gum rubber roll is a frequently overlooked yet exceptionally versatile material used across various industries. Known for its elastic properties and durability, gum rubber rolls are manufactured from natural rubber latex, which provides a dense, strong, and flexible product. This article explores the characteristics, benefits, and applications of gum rubber rolls, shedding light on why they are an essential material in many sectors.

Characteristics of Gum Rubber Rolls

Gum rubber rolls are characterized by their unique properties, which make them stand out in the market. Firstly, they possess excellent tensile strength, allowing them to withstand substantial stretching and deformation without damage. This characteristic makes gum rubber rolls ideal for applications that require flexibility and resilience.

Furthermore, gum rubber is known for its high coefficient of friction. This means that it provides a superior grip, making it useful for various sporting and industrial applications where traction is crucial. Additionally, gum rubber rolls have good resistance to abrasions, which extends their lifespan and efficacy in demanding environments.

Another key attribute is the natural non-porous surface of gum rubber. This feature makes it resistant to water, gases, and many chemicals, thus enabling its usage in diverse environments without the risk of degradation.

Benefits of Using Gum Rubber Rolls

The benefits of using gum rubber rolls are manifold

. Firstly, their durability means that they are a cost-effective option in the long run, as they require less frequent replacement compared to other materials. The flexibility of gum rubber also contributes to a decrease in the risk of breakage or damage during installation or use.gum rubber roll

Moreover, gum rubber rolls are highly customizable. They can be produced in various thicknesses, widths, and lengths, allowing them to meet specific requirements for different applications. This adaptability is one of the reasons why gum rubber rolls are favored in various sectors.

In addition to their physical properties, gum rubber rolls are also environmentally friendly. Being made from natural rubber, they can be sourced sustainably under proper practices, thus appealing to companies aiming to reduce their carbon footprint and embrace green initiatives.

Applications of Gum Rubber Rolls

Gum rubber rolls find use in a wide range of applications. One of the most notable is in the flooring industry. Many sports facilities and gyms utilize gum rubber rolls for their floors due to the superior shock-absorbent qualities that help minimize injuries during physical activities. The skid resistance and cushion properties of gum rubber make it an excellent choice for high-impact sports environments.

Beyond recreational spaces, gum rubber rolls are also used in industrial settings. They are commonly applied as conveyor belts, where the friction and durability of gum rubber contribute to safe and efficient transportation of goods. Additionally, in manufacturing, they are often used to create protective mats and beading, reducing noise and vibration and providing a non-slip surface for workers.

The automotive industry benefits from gum rubber rolls as well, where they serve as seals and gaskets, providing effective insulation against heat and preventing leaks. These applications highlight the crucial role that gum rubber plays in ensuring safety and efficiency in various products and processes.

Conclusion

In summary, gum rubber rolls are an invaluable material celebrated for their versatility and wide-ranging applications. With characteristics such as durability, flexibility, and excellent grip, they are widely used in sports facilities, industrial settings, and even the automotive industry. As industries continue to evolve, the demand for innovative, sustainable materials will grow, keeping gum rubber rolls relevant for years to come. Embracing this material means recognizing its ability to contribute to more efficient and safer practices across numerous fields, ultimately driving progress in both manufacturing and consumer-oriented applications.