Oct . 18, 2024 16:11 Back to list

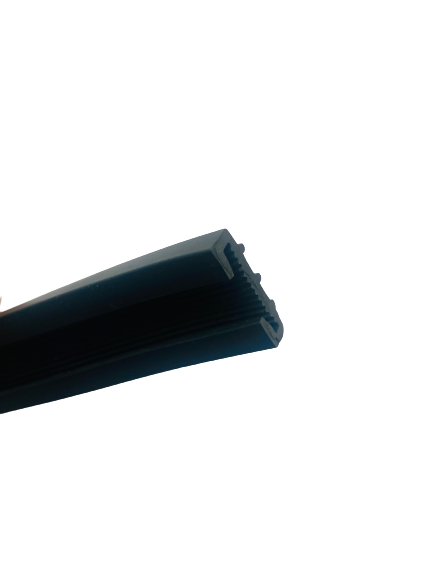

OEM PU Sealing Strips for Doors and Windows for Optimal Insulation and Durability

Understanding OEM PU Door and Window Sealing Strips A Comprehensive Guide

In the construction and manufacturing industries, the importance of sealing strips cannot be overstated. They play a crucial role in ensuring the integrity of structures by enhancing insulation, preventing air leaks, and improving overall energy efficiency. Among the various types of sealing materials available, OEM (Original Equipment Manufacturer) PU (Polyurethane) door and window sealing strips stand out for their exceptional durability and performance. This article aims to explore the features, benefits, applications, and considerations associated with OEM PU door and window sealing strips.

What are OEM PU Sealing Strips?

OEM PU sealing strips are specifically designed sealing solutions tailored for manufacturers looking to integrate high-quality materials into their products. The OEM designation indicates that these strips are produced to meet the precise specifications and quality standards set by the manufacturers who incorporate them into their products, such as doors and windows. PU, or polyurethane, is a versatile polymer known for its flexibility, resilience, and excellent adhesion properties.

Features of OEM PU Sealing Strips

1. Weather Resistance PU sealing strips are engineered to withstand various weather conditions, including extreme temperatures, humidity, and UV exposure. This quality ensures that they maintain their integrity and performance over time.

2. Flexibility and Compression Recovery One of the standout features of PU sealing strips is their remarkable flexibility. They can compress and expand without losing their original shape, making them ideal for applications subject to movement and shifting.

3. Excellent Insulation Properties OEM PU sealing strips provide superior thermal and acoustic insulation. This feature not only enhances energy efficiency by minimizing air leakage but also creates a more comfortable indoor environment by reducing outside noise.

4. Ease of Installation Designed for convenience, these sealing strips often come with strong adhesive backing, allowing for quick and straightforward installation. Manufacturers find this feature advantageous, as it reduces labor costs and installation time.

5. Customizability OEM manufacturers can request sealing strips in various shapes, sizes, and hardness levels to suit specific applications. This customization greatly enhances the versatility of their products.

Benefits of Using OEM PU Sealing Strips

1. Energy Efficiency By providing a tight seal around doors and windows, PU sealing strips help to reduce energy consumption associated with heating and cooling, leading to lower energy bills and a reduced carbon footprint.

2. Longevity The durability of PU makes these sealing strips resistant to wear and tear, reducing the need for frequent replacements. This longevity translates to cost savings for manufacturers and end-users alike.

oem pu door and window sealing strip

3. Enhanced Aesthetics OEM PU sealing strips can be designed to match various architectural styles and colors, ensuring that they blend seamlessly with the overall aesthetic of the building.

4. Increased Property Value High-quality sealing solutions contribute to a building's overall quality, leading to higher property values. Buyers are increasingly looking for homes and commercial spaces that offer energy efficiency and durability.

5. Compliance with Standards OEM sealing strips are often manufactured in compliance with industry standards and regulations, ensuring that they meet safety and environmental requirements.

Applications of OEM PU Sealing Strips

OEM PU door and window sealing strips are used in a variety of applications, including

- Residential Buildings For doors and windows in homes, these sealing strips provide insulation and protect against the elements, enhancing comfort and energy savings. - Commercial Structures Retail outlets, offices, and warehouses benefit from the reliability and performance of PU sealing strips to maintain energy efficiency.

- Automotive In the automotive industry, PU sealing strips are used to ensure airtightness and enhance the longevity of vehicle components.

- Industrial Machinery Equipment and machinery often utilize these sealing strips to protect internal mechanisms from dust and moisture.

Considerations When Choosing OEM PU Sealing Strips

When selecting OEM PU sealing strips, manufacturers should consider factors such as the specific application, environmental conditions, and compliance with relevant standards. Additionally, working closely with suppliers can ensure that the chosen seals meet all performance criteria and are tailored to the needs of the project.

Conclusion

OEM PU door and window sealing strips are essential components in modern construction and manufacturing. Their superior properties, combined with the advantages of customization and compliance, make them ideal for a wide range of applications. By investing in quality sealing solutions, manufacturers can enhance their products' performance and durability while contributing to a more energy-efficient future.