Feb . 11, 2025 00:08 Back to list

L-shaped staircase anti-skid strip

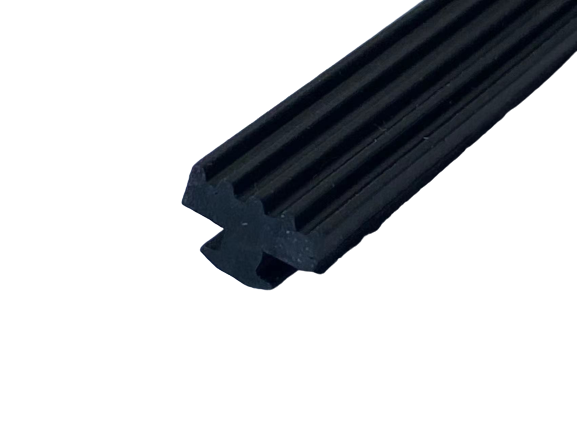

OEM ship sealing strips, often overlooked, are pivotal components in the maritime industry, providing essential protection and efficiency for vessels of all sizes. These sealing strips are integral for preventing water ingress, reducing noise pollution, and enhancing fuel efficiency by improving the aerodynamics of a ship. Understanding the value and application of OEM ship sealing strips can significantly influence a vessel's performance and longevity, while also contributing to environmental sustainability.

From an expertise standpoint, OEM (Original Equipment Manufacturer) sealing strips are crafted to meet precise specifications and tolerances. This ensures that they fit perfectly with the designated ship model, providing optimal performance without the need for modifications or adjustments. The precision involved in designing these components underscores the importance of collaboration between naval architects, marine engineers, and OEM manufacturers. This professional synergy guarantees the development of sealing solutions that match the exact needs of modern maritime vessels. The authoritativeness of OEM ship sealing strips is supported by comprehensive research and testing. Manufacturers typically put these products through rigorous quality assurance processes, simulating real-world maritime conditions to verify their effectiveness. This ensures that ship operators receive a product that not only performs well under normal circumstances but can also stand up to extreme situations, such as severe weather or high-pressure environments. The reliability of OEM seals underpins their authoritative status in the maritime industry. Trustworthiness of OEM ship sealing strips is crucial for ship builders and owners. These stakeholders rely on the integrity and longevity of sealing strips to safeguard valuable assets and crew members. Trust is built through a consistent track record of performance and positive feedback from customers across the industry. Trustworthy OEMs provide ample documentation and support to demonstrate their product's reliability, and they are often willing to collaborate with clients to tailor solutions that meet specific operational needs. In conclusion, OEM ship sealing strips are indispensable elements of modern maritime practices. They provide essential benefits such as protection against water ingress, noise reduction, fuel efficiency, and regulatory compliance. Their role is supported by solid experience, professional expertise, authoritative research, and trustworthy partnerships between manufacturers and maritime operators. Investing in high-quality OEM sealing strips is not merely a precaution; it is a strategic move that ensures vessels operate optimally and sustainably, safeguarding both human and environmental interests.

From an expertise standpoint, OEM (Original Equipment Manufacturer) sealing strips are crafted to meet precise specifications and tolerances. This ensures that they fit perfectly with the designated ship model, providing optimal performance without the need for modifications or adjustments. The precision involved in designing these components underscores the importance of collaboration between naval architects, marine engineers, and OEM manufacturers. This professional synergy guarantees the development of sealing solutions that match the exact needs of modern maritime vessels. The authoritativeness of OEM ship sealing strips is supported by comprehensive research and testing. Manufacturers typically put these products through rigorous quality assurance processes, simulating real-world maritime conditions to verify their effectiveness. This ensures that ship operators receive a product that not only performs well under normal circumstances but can also stand up to extreme situations, such as severe weather or high-pressure environments. The reliability of OEM seals underpins their authoritative status in the maritime industry. Trustworthiness of OEM ship sealing strips is crucial for ship builders and owners. These stakeholders rely on the integrity and longevity of sealing strips to safeguard valuable assets and crew members. Trust is built through a consistent track record of performance and positive feedback from customers across the industry. Trustworthy OEMs provide ample documentation and support to demonstrate their product's reliability, and they are often willing to collaborate with clients to tailor solutions that meet specific operational needs. In conclusion, OEM ship sealing strips are indispensable elements of modern maritime practices. They provide essential benefits such as protection against water ingress, noise reduction, fuel efficiency, and regulatory compliance. Their role is supported by solid experience, professional expertise, authoritative research, and trustworthy partnerships between manufacturers and maritime operators. Investing in high-quality OEM sealing strips is not merely a precaution; it is a strategic move that ensures vessels operate optimally and sustainably, safeguarding both human and environmental interests.