joulu . 04, 2024 16:44 Back to list

Neoprene Rubber Sheets for Diaphragm Applications and Various Uses

Understanding Neoprene Diaphragm Rubber Sheets Versatile Solutions for Various Applications

Neoprene diaphragm rubber sheets are remarkably versatile materials that have gained popularity in various industries, thanks to their unique properties and adaptability. Neoprene, a synthetic rubber known for its durability and flexibility, is a key ingredient in these rubber sheets, making them ideal for applications requiring resilience, chemical resistance, and temperature stability.

What is Neoprene?

Neoprene, also known as polychloroprene, was first developed in the 1930s and has since become a staple in the rubber industry. It is a synthetic rubber that retains its flexibility and strength across a wide range of temperatures, typically from -40°F to 175°F (-40°C to 80°C). This unique characteristic makes neoprene an excellent choice for many applications, including automotive, construction, and marine environments.

Characteristics of Neoprene Diaphragm Rubber Sheets

Neoprene diaphragm rubber sheets boast several key features that contribute to their effectiveness in various applications

1. Durability Neoprene is resistant to wear and tear, making it an excellent material for applications that involve constant movement or pressure. Its resistance to abrasion ensures longevity, reducing the need for frequent replacements.

2. Chemical Resistance One of the standout properties of neoprene is its resistance to a wide range of chemicals, oils, and solvents. This makes it a suitable choice for industries such as automotive and chemical processing, where exposure to harsh substances is common.

3. Temperature Stability Neoprene maintains its performance even in extreme temperatures. This thermal stability makes it ideal for environments that fluctuate between hot and cold conditions.

4. Flexibility and Elasticity The elastic nature of neoprene allows for significant deformation without permanent damage. This makes neoprene diaphragm rubber sheets suitable for applications requiring movement, such as seals, gaskets, and diaphragms.

5. Water Resistance Neoprene is inherently resistant to water, making it an excellent choice for applications involving exposure to moisture, whether indoors or outdoors.

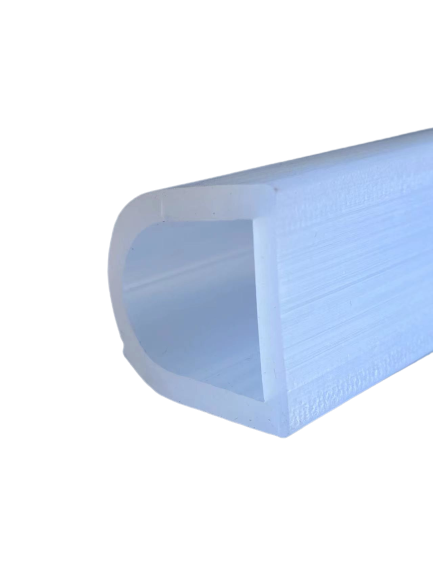

neoprene diaphragm rubber sheet

Applications of Neoprene Diaphragm Rubber Sheets

Neoprene diaphragm rubber sheets find applications across various sectors, including

- Automotive Industry In vehicles, neoprene rubber is commonly used for gaskets, seals, and diaphragm applications due to its durability and ability to withstand extreme conditions, including oil exposure.

- Aerospace The aerospace industry utilizes neoprene rubber sheets for similar reasons. Their lightweight nature and resilience against high temperatures and chemicals make them suitable for many aircraft components.

- Construction and HVAC In construction, neoprene rubber sheets are often used for roofing membranes, sealants, and vibration dampening. In HVAC systems, they serve as gaskets and seals, providing efficiency in thermal insulation.

- Medical Equipment Neoprene’s biocompatibility makes it a common choice for medical applications, including seals in pumps and valves.

- Marine Applications The water-resistant properties of neoprene make it ideal for marine environments, where components are routinely exposed to moisture and saltwater.

Conclusion

Neoprene diaphragm rubber sheets are invaluable tools in various industries due to their unique properties and versatility. From automotive to marine applications, the benefits of neoprene—such as durability, chemical resistance, and temperature stability—ensure that products made from this material perform reliably over time. As industries continue to evolve, the use of neoprene diaphragm rubber sheets is likely to expand, proving that this synthetic rubber remains a crucial component in modern engineering and manufacturing.

Whether you are looking for reliable materials for an automotive project, seeking solutions for HVAC systems, or requiring durable components for medical devices, neoprene diaphragm rubber sheets stand out as a solution that combines flexibility, resilience, and adaptability under various conditions. As we navigate a future of increasing technological reliance, the demand for such high-performance materials will continue to grow, solidifying neoprene's role in innovative applications.