joulu . 03, 2024 10:19 Back to list

rubber seals for wooden doors and windows exporter

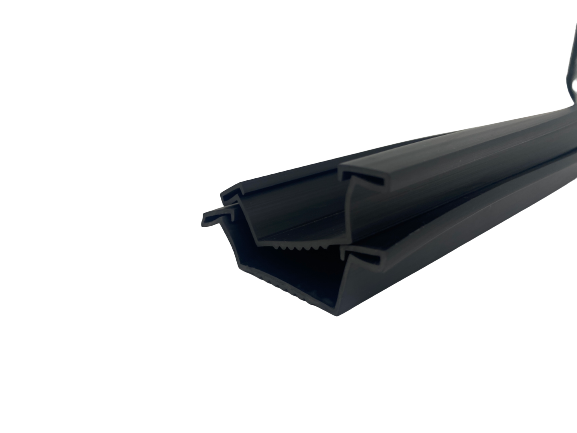

Rubber Seals for Wooden Doors and Windows Exporter

In today's rapidly evolving construction and manufacturing industries, the demand for high-quality materials is more important than ever. Among these materials, rubber seals for wooden doors and windows have emerged as a crucial component, playing a significant role in ensuring energy efficiency, durability, and aesthetic appeal. As an exporter of rubber seals, understanding the market dynamics, manufacturing processes, and benefits of these seals is essential for success.

Importance of Rubber Seals

Rubber seals are designed to prevent air and water infiltration, which is particularly critical for wooden doors and windows. Wooden structures can be susceptible to the elements, leading to issues such as rotting, warping, and a decrease in thermal efficiency. By employing high-quality rubber seals, manufacturers can enhance the longevity of wooden installations and minimize maintenance costs.

These seals serve various purposes, including

1. Weatherproofing Rubber seals protect against rain, wind, dust, and insects, creating a more comfortable indoor environment. 2. Energy Efficiency By preventing drafts, rubber seals help maintain stable indoor temperatures, reducing heating and cooling costs.

3. Noise Reduction Quality seals can act as sound barriers, leading to a more peaceful indoor atmosphere.

4. Aesthetics Rubber seals can be designed in various colors and finishes, providing a visually appealing solution that compliments wooden features.

Manufacturing Process

The process of manufacturing rubber seals involves several key steps. Initially, high-grade rubber materials are sourced, ensuring that the final product meets international quality standards. The production process typically includes

2. Molding The compounded rubber is shaped into the desired seal profiles using molds, which can be customized based on specifications.

3. Curing The molded seals undergo a curing process, where they are heated to ensure proper vulcanization, resulting in enhanced elasticity and strength.

rubber seals for wooden doors and windows exporter

4. Quality Control After production, seals undergo rigorous testing to ensure they meet predefined standards regarding size, shape, and physical properties such as tensile strength and hardness.

Market Dynamics

As an exporter of rubber seals for wooden doors and windows, understanding the market trends is crucial. The demand for these products is on the rise, driven by a growing focus on sustainable construction practices. Additionally, the increase in new residential and commercial construction projects presents an opportunity for exporters to expand their reach.

Regions such as North America and Europe are prime markets due to stringent building codes and a push towards energy-saving solutions. On the other hand, emerging markets in Asia and South America are also seeing rapid growth, attributed to urbanization and increased disposable incomes.

Challenges and Opportunities

While the market for rubber seals is promising, exporters may face several challenges, including

1. Competition The global market is competitive, with numerous manufacturers producing similar products. Innovation and customization can help distinguish one’s offerings.

2. Regulations Compliance with local and international standards is vital. Exporters must stay abreast of any changes in regulations that might affect their products.

3. Supply Chain Issues Global supply chains have been disrupted in recent years, affecting the timely delivery of raw materials. Building strong relationships with suppliers can mitigate these risks.

Despite these challenges, opportunities abound. Advances in manufacturing technology, such as automated production lines and improved material formulations, can increase efficiency and reduce costs. Additionally, a growing trend towards eco-friendly materials provides a chance for exporters to innovate with sustainable options in their product lines.

Conclusion

Rubber seals for wooden doors and windows are more than just functional components; they are integral to modern construction practices that prioritize longevity, energy efficiency, and aesthetics. As an exporter in this niche market, it is essential to focus on quality, market trends, and customer needs to thrive. By leveraging manufacturing innovations and staying informed about industry dynamics, exporters can capitalize on the growing demand for rubber seals and contribute significantly to the sustainable development of the construction sector.